Atomizing pump head

A technology of spray pump and nozzle head, which is applied in the field of spray pump head, which can solve the problems of fast liquid flow, affecting user experience, pressure difference, etc., achieves the effect of fewer parts, convenient processing, and helpful spring reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

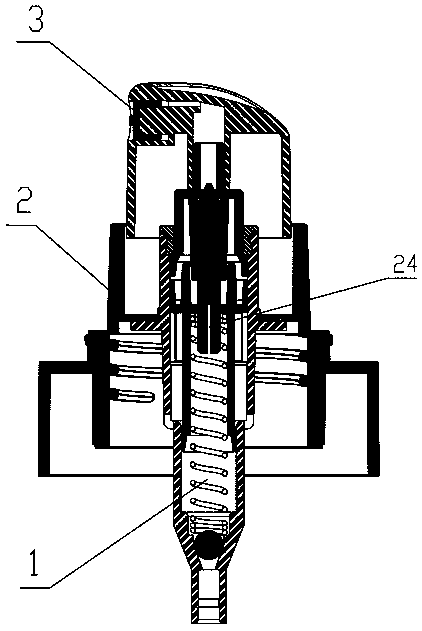

[0031] The invention relates to a high-efficiency spray pump head, such as figure 1 As shown, it consists of a pump core 1, a middle cover 2, and a nozzle head 3. The pump core is fixed in the center of the middle cover, and the nozzle head is set on the upper side of the middle cover, and moves up and down relative to the middle cover. The nozzle head is connected with a spray channel, and the lower part of the pump core is stretched under the liquid level of the bottle cavity through a flexible pipe.

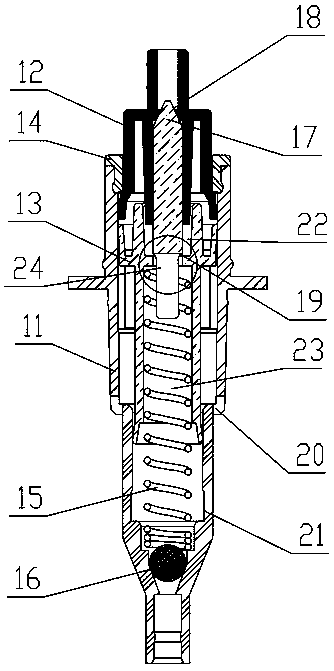

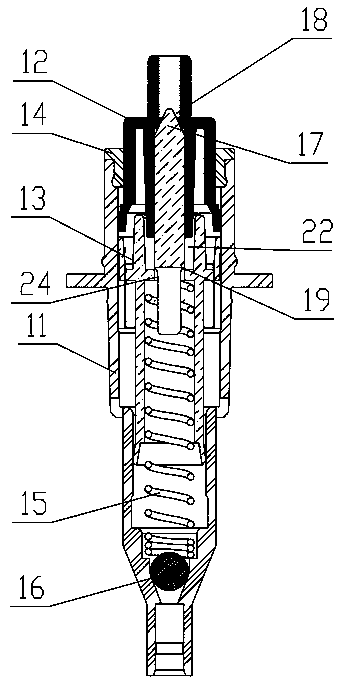

[0032] like figure 2 As shown, the pump core includes a pump core main body 11, an upper piston 12, a reverse thrust plug 13, a sealing ring 14, etc., the pump core main body is a hollow barrel-shaped structure with a multi-layer stepped structure, the pump core main body and the upper piston, reverse thrust The plug is slidingly fitted, and the anti-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com