A graphene-wrapped nickel-nickel oxide catalyst and its application in the preparation of lactic acid

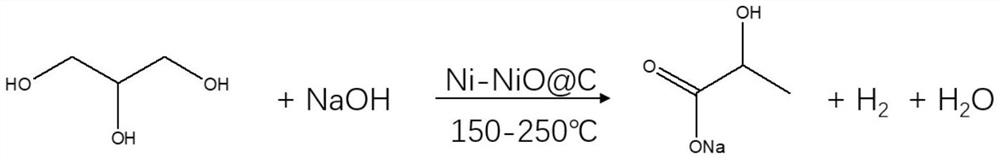

A graphene encapsulation and catalyst technology, which is applied in the oxidation preparation of carboxylic acid, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. The effect of protecting metal loss, shortening reaction time and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

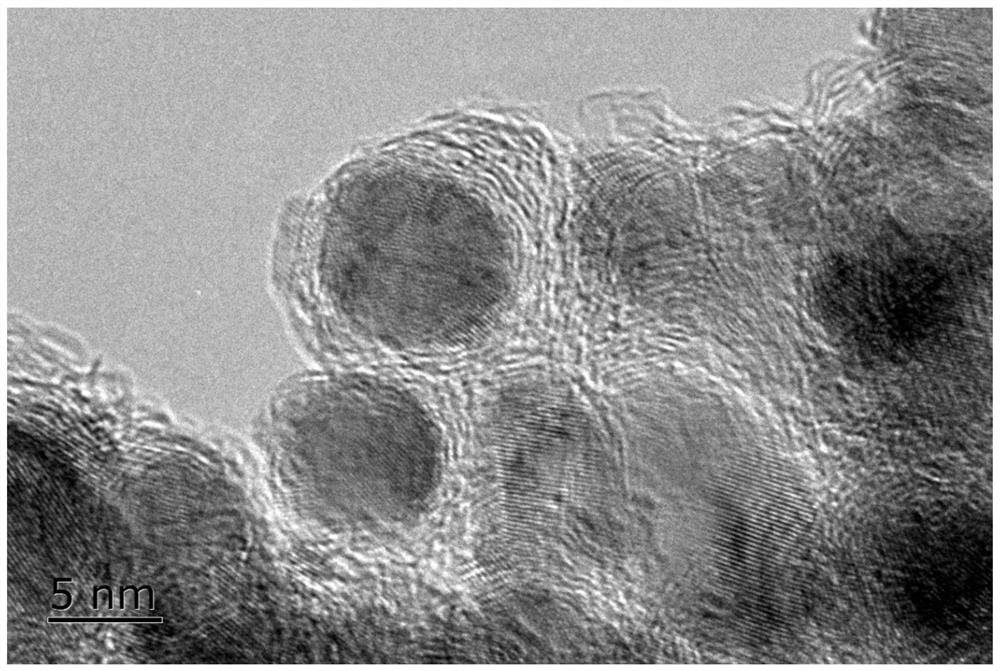

[0031] The preparation of graphene-wrapped nickel-nickel oxide catalyst Ni-NiO@C includes the following steps:

[0032] (1) Preparation of catalyst precursor CA-Ni: 17.8g Ni(NO 3 ) 2 ·6H 2 O, 11.72g of citric acid was dissolved in 5mL of water, stirred at 70°C for 6h to gel, and then dried in a vacuum oven at 60°C for 10h to obtain the precursor powder CA-Ni;

[0033] (2) Preparation of encapsulated catalyst Ni@C: put the above precursor CA-Ni in 30mL / min N 2 In the airflow, heat up to 600°C and maintain it for 3 hours. The heating rate is 5°C / min. The gas is taken out and the calcined catalyst is poured into 1mol / L sulfuric acid solution and stirred at 70°C for 12h to wash away the insufficiently wrapped catalyst. nickel particles. The acid-washed catalyst was fully washed several times in distilled water to achieve neutrality, and then dried in a vacuum freeze dryer to obtain the catalyst Ni@C;

[0034] (3) Preparation of graphene-wrapped nickel-nickel oxide catalyst Ni-N...

Embodiment 2

[0037] The preparation of graphene-wrapped nickel-nickel oxide catalyst Ni-NiO@C includes the following steps:

[0038] (1) Preparation of catalyst precursor CA-Ni: 17.8g Ni(NO 3 ) 2 ·6H 2 O, 11.72g of citric acid was dissolved in 5mL of water, stirred at 60°C for 6h to gel, and then dried in a vacuum oven at 50°C for 12h to obtain the precursor powder CA-Ni;

[0039] (2) Preparation of encapsulated catalyst Ni@C: put the above precursor CA-Ni in 30mL / min N 2 In the airflow, heat up to 500°C and keep it for 4 hours, the temperature rise rate is 5°C / min, the gas is taken out, the roasted catalyst is poured into 1mol / L sulfuric acid solution, and stirred at 70°C for 12h to wash away the insufficiently wrapped catalyst. nickel particles. The acid-washed catalyst was fully washed several times in distilled water to achieve neutrality, and then dried in a vacuum freeze dryer to obtain the catalyst Ni@C;

[0040] (3) Preparation of graphene-wrapped nickel-nickel oxide catalyst ...

Embodiment 3

[0042] The preparation of graphene-wrapped nickel-nickel oxide catalyst Ni-NiO@C includes the following steps:

[0043] (1) Preparation of catalyst precursor CA-Ni: 17.8g Ni(NO 3 ) 2 ·6H 2 O, 11.72g of citric acid was dissolved in 5mL of water, stirred at 80°C for 6h to gel, and then placed in a vacuum oven at 70°C for 8h to obtain the precursor powder CA-Ni;

[0044] (2) Preparation of encapsulated catalyst Ni@C: put the above precursor CA-Ni in 30mL / min N 2 In the airflow, heat up to 700°C and maintain it for 2 hours. The heating rate is 5°C / min. The gas is taken out and the calcined catalyst is poured into a 1mol / L sulfuric acid solution and stirred at 70°C for 12 hours to wash away the insufficiently wrapped catalyst. nickel particles. The acid-washed catalyst was fully washed several times in distilled water to achieve neutrality, and then dried in a vacuum freeze dryer to obtain the catalyst Ni@C;

[0045] (3) Preparation of graphene-wrapped nickel-nickel oxide cata...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com