Artificial surface plasmon transmission line-based filtering array antenna and manufacturing method thereof

An artificial surface plasmon and filter array technology, applied in antenna arrays, specific array feeding systems, antennas, etc., can solve problems such as low efficiency, high frequency loss, and difficult to control, and achieve small volume and high emission. Efficiency, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

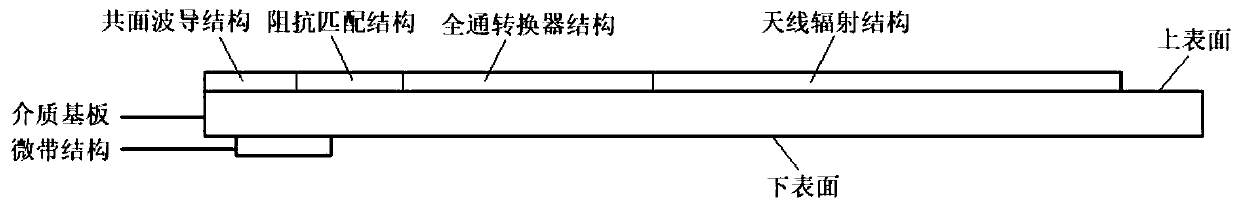

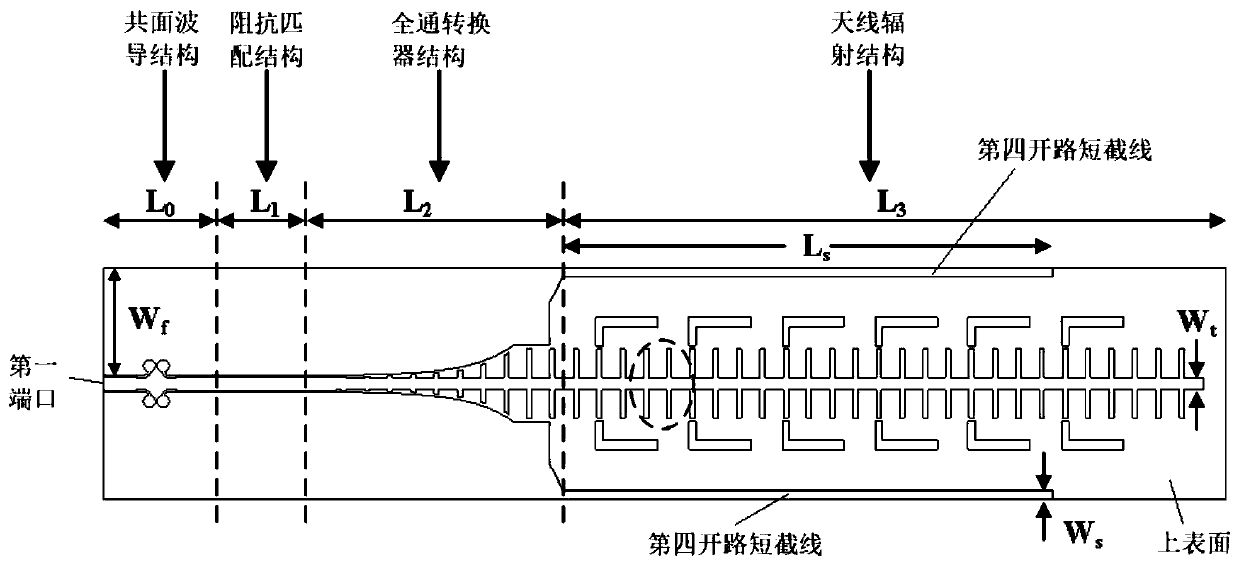

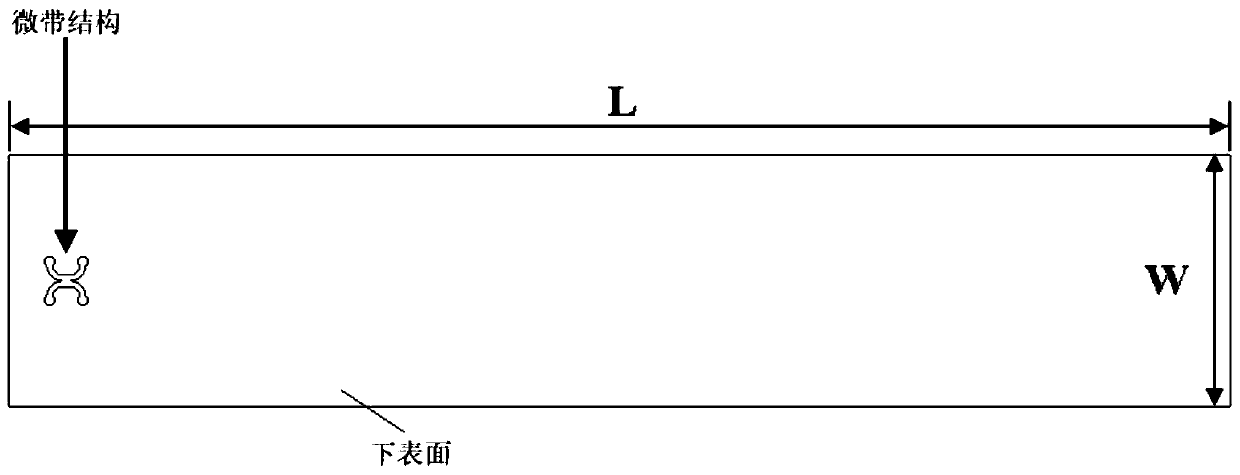

[0031] In this embodiment, the filter array antenna based on the artificial surface plasmon transmission line has a structure such as figure 1 As shown, it includes a dielectric substrate, the upper surface of the dielectric substrate is provided with a coplanar waveguide structure, an impedance matching structure, an all-pass converter structure and an antenna radiation structure connected in sequence, and the lower surface of the dielectric substrate is provided with a microstrip structure .

[0032] In this embodiment, the dielectric substrate is a rectangular thin plate, and the "upper surface" and "lower surface" of the dielectric substrate are only used to distinguish the two surfaces of the dielectric substrate, and do not represent the "upper surface" when the filter array antenna of the present invention works Must be up or the "lower surface" must be down. refer to figure 1 , when the upper surface of the dielectric substrate is upward, the filter array antenna of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com