Preparation method of 2:17 type rare earth-iron-nitrogen composite magnetic material for high frequency use

A composite magnetic material and technology of magnetic materials, which are applied in the field of preparation of 2:17 type rare earth-iron-nitrogen composite magnetic materials for high frequency, can solve the problems of electromagnetic wave absorption and shielding failure, large eddy current loss, etc. Morphology rules, raw material cost reduction, and the effect of improving nitrogen absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A method for preparing a 2:17 type rare earth-iron-nitrogen composite magnetic material for high frequency, comprising the following steps:

[0042] 1) Preparation of 2:17 type rare earth-iron-nitrogen magnetic powder

[0043] S11: Use rare earth oxides, carbonyl iron powder and / or iron oxides, and reducing agents as raw materials to perform a reduction diffusion reaction to obtain a 2:17 type rare earth-iron magnetic material Re 2 Fe 17 ; Wherein, R is a rare earth element;

[0044] S12: performing hydrogen absorption and dehydrogenation treatment on the 2:17 type rare earth-iron magnetic material obtained in S11;

[0045] S13: The product obtained in S12 is subjected to a nitrogen absorption reaction, washed with water, dried, and ball milled to obtain a 2:17 type rare earth-iron-nitrogen magnetic powder;

[0046] 2) Preparation of 2:17 type rare earth-iron-nitrogen composite magnetic materials for high frequency

[0047] S21: Mix 2:17 type rare earth-iron-nitroge...

Embodiment

[0083] 1. Preparation of 2:17 type rare earth-iron-nitrogen magnetic powder

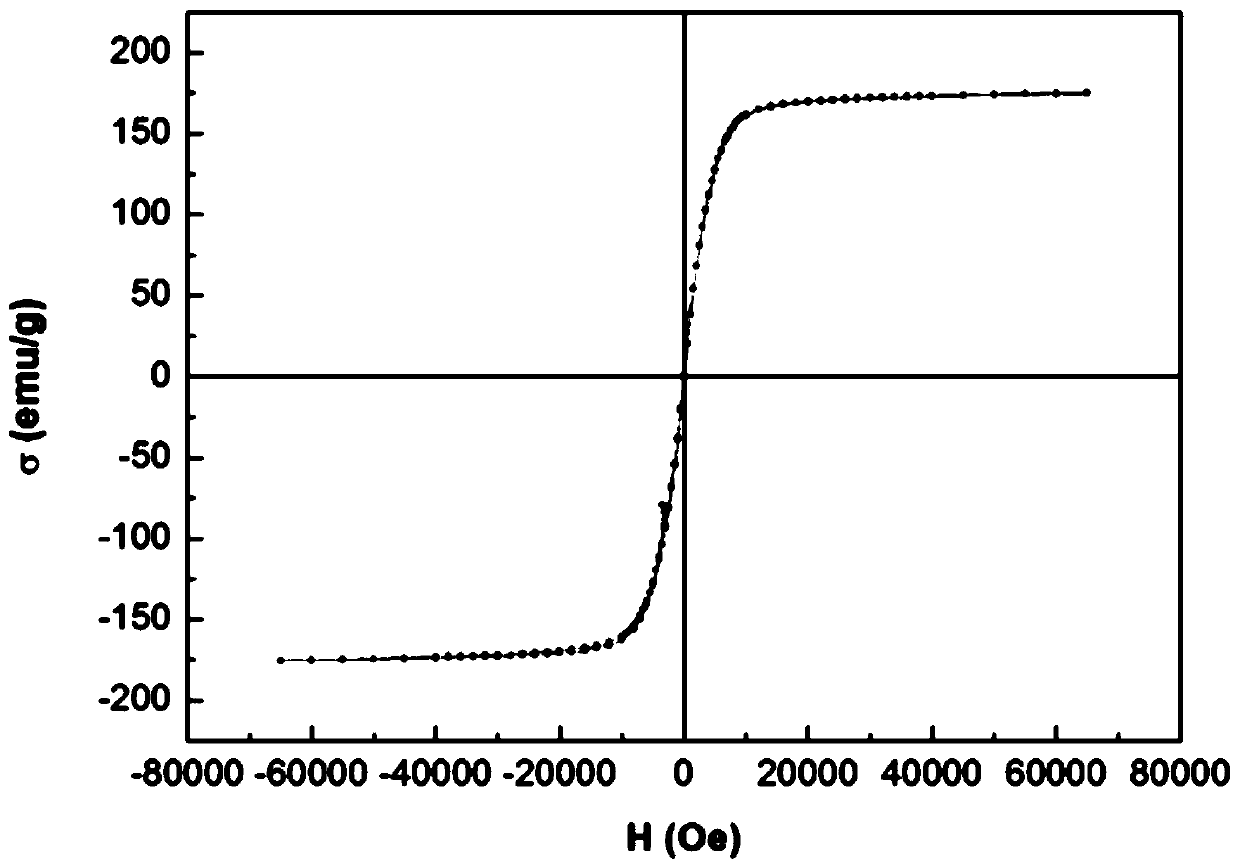

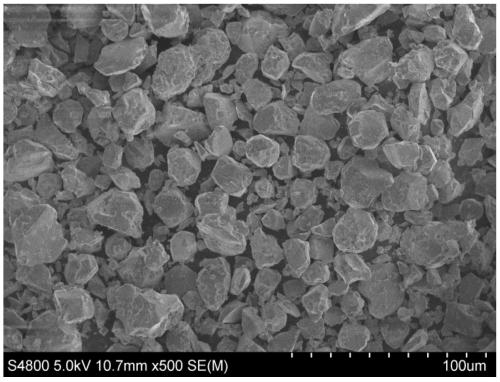

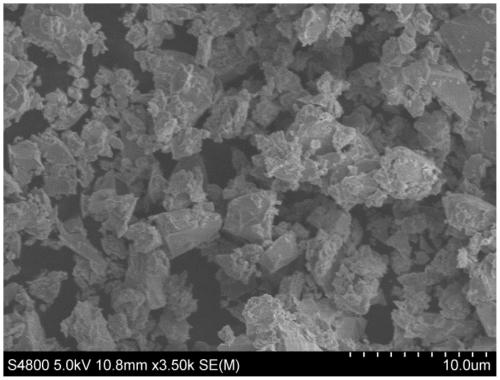

[0084] Nd with a purity of 99.9% is selected 2 o 3 Carbonyl iron powder (average particle size is 5 μ m) of powder and purity 98.6%, according to equation (1) calculate the stoichiometric dose of each reactant required, Nd 2 o 3 The added mass is over 30% stoichiometric, the metal Ca particle size is 3-5mm, and the added amount is based on Nd 2 o 3 The actual amount added is metered, and the chemical dosage over metered is 50%. The reduction-diffusion reaction was carried out at 1160° C. for 4 hours under the protection of argon. Then draw a high vacuum to 10 -5 mbar, into H 2 Gas, heat up to 250°C and keep it warm for 2 hours to absorb hydrogen; switch to Ar gas, heat up to 400°C, stop flowing Ar, and vacuum for 40 minutes to carry out dehydrogenation. Stop vacuuming, feed N 2 Gas (flow rate is 500sccm) and H 2 Gas (flow rate: 50 sccm) mixed gas, the temperature was raised to 480° C., and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com