Rail wear degree identification method and system

A wear degree and recognition method technology, applied in character and pattern recognition, image data processing, instruments, etc., can solve the problems of inaccurate judgment, inability to collect two-dimensional images, and high deployment costs, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

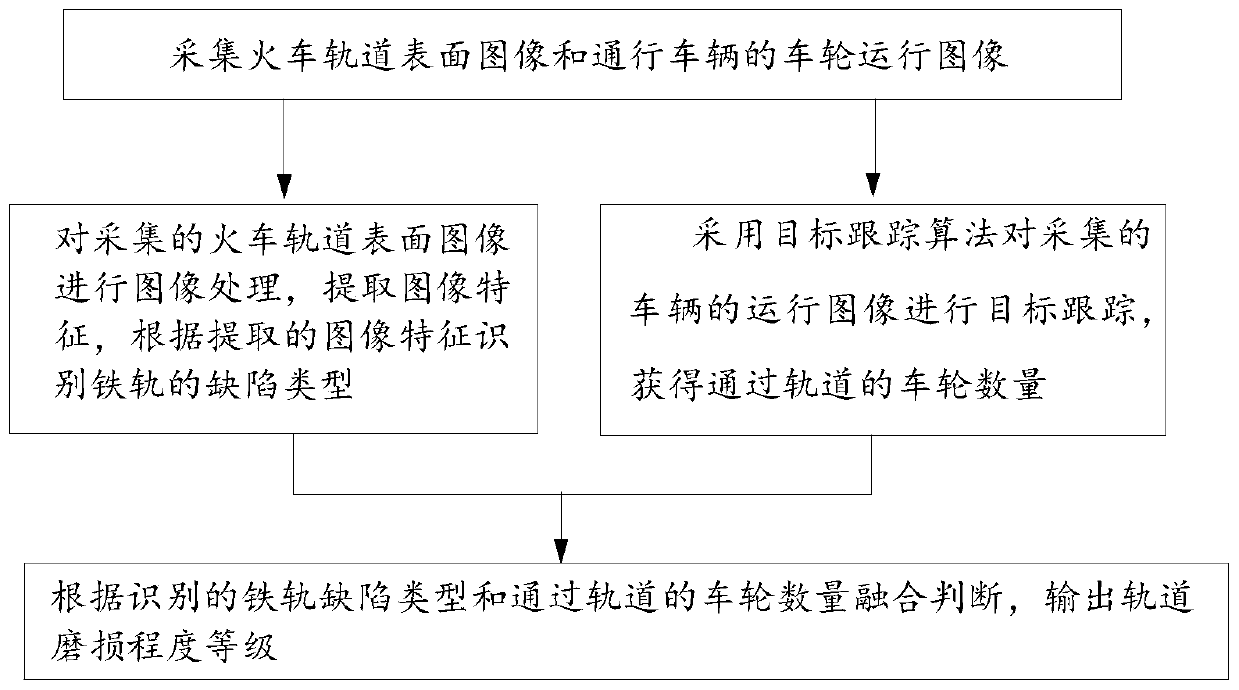

[0087] This embodiment provides an identification system for the degree of track wear, including:

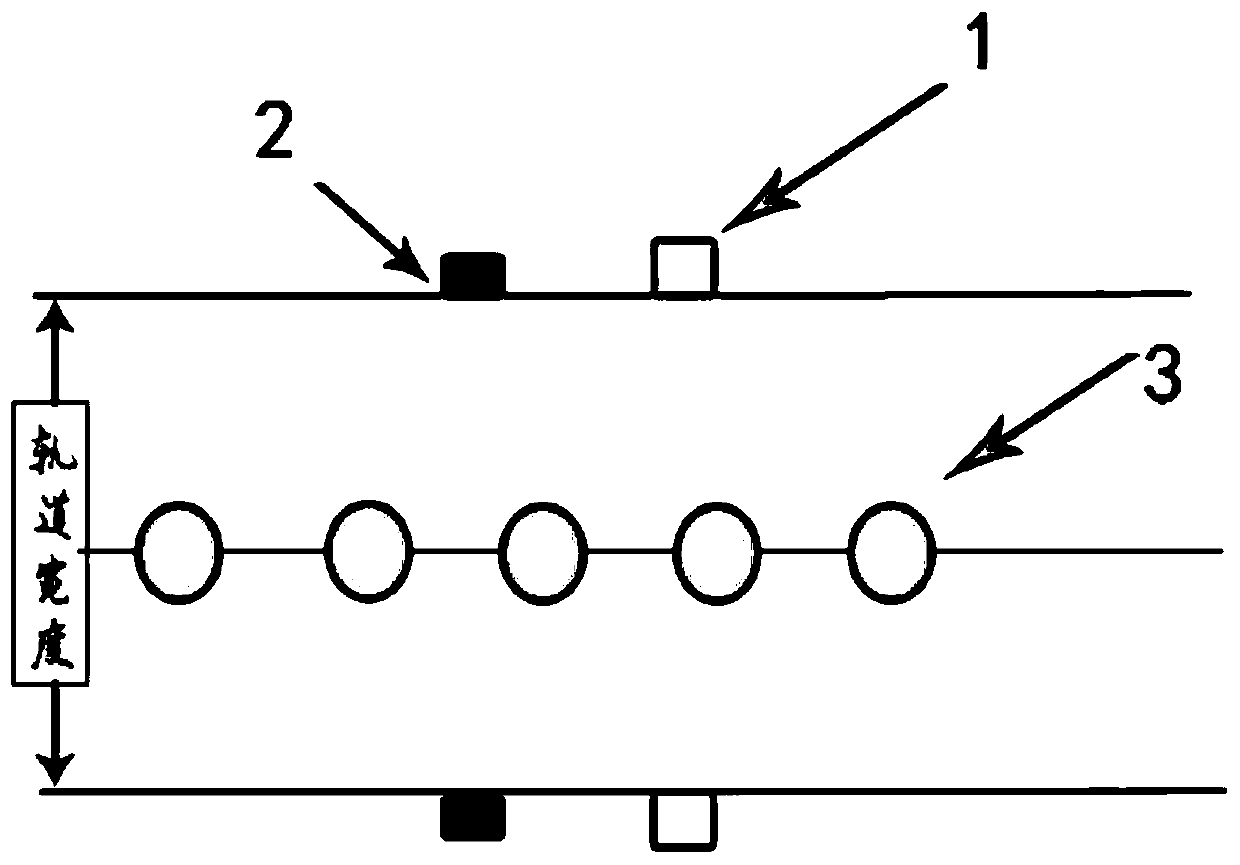

[0088] Image acquisition module: used to acquire train track surface images and wheel running images of passing vehicles;

[0089] Defect type identification module: used to perform image processing on the collected train track surface image, extract image features, and identify the defect type of the rail according to the extracted image features;

[0090] Wheel counting module: it is used to track the target of the collected running image of the vehicle by using the target tracking algorithm to obtain the number of wheels passing through the track;

[0091] Track wear degree grade judgment module: used to fuse and judge the identified rail defect type and the number of wheels passing through the track, and output the track wear degree grade.

Embodiment 3

[0093] This embodiment also provides an electronic device, including a memory, a processor, and computer instructions stored in the memory and run on the processor. When the computer instructions are executed by the processor, the method in the first embodiment is completed. step.

Embodiment 4

[0095] This embodiment also provides a computer-readable storage medium for storing computer instructions, and when the computer instructions are executed by a processor, the steps of the method in the first embodiment are completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com