Tartary buckwheat drying device

A drying device, tartary buckwheat technology, applied in the direction of drying, dryer, heating device, etc., can solve the problems that the drying temperature cannot be effectively controlled, and the drying equipment cannot be effectively, fully and uniformly dried, and achieve the goal of drying Uniform and thorough, prevent the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

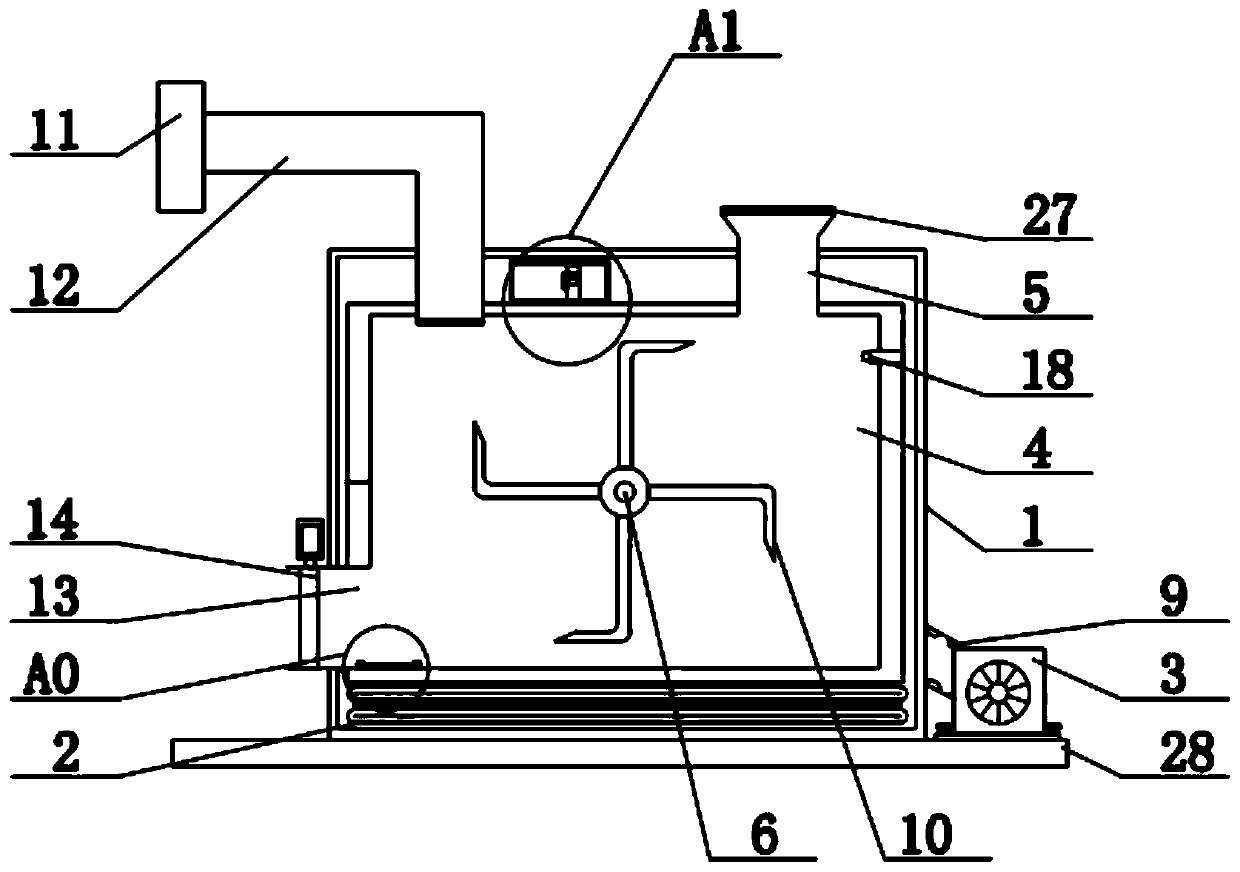

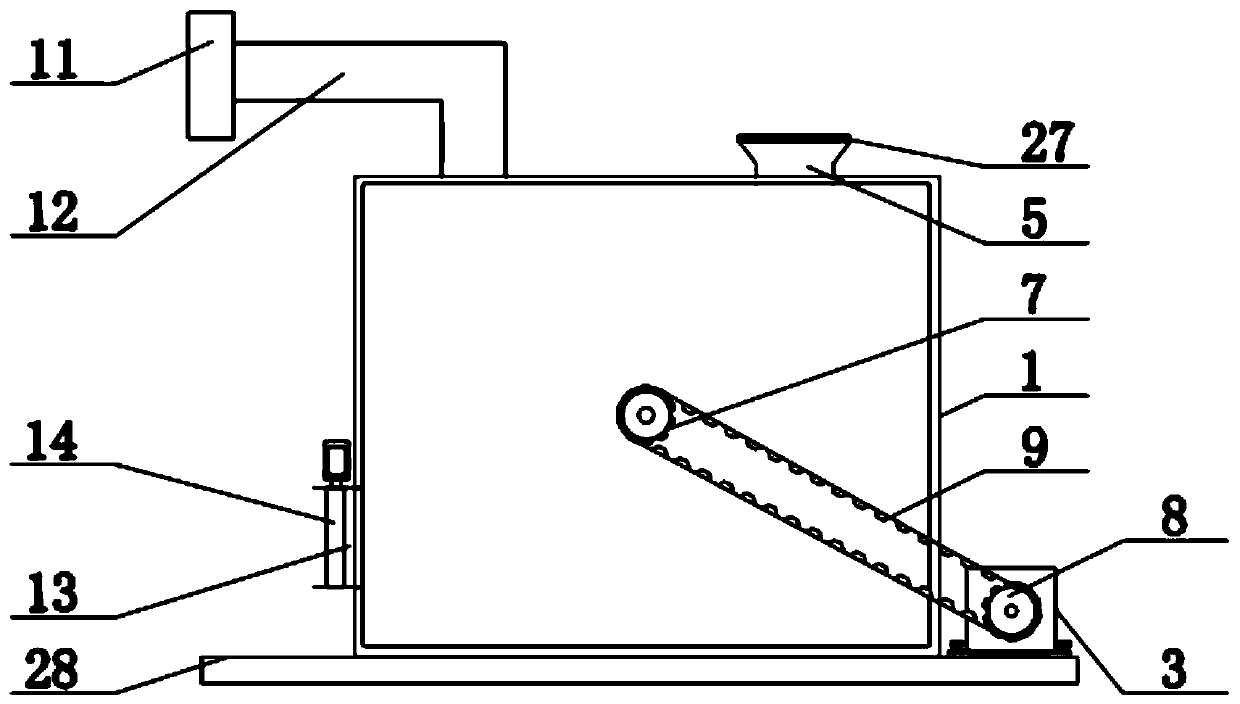

[0028] See figure 1 —5. A tartary buckwheat drying device, comprising a device housing 1, an electric heating wire 2, a rotating motor 3, a drying cavity 4 is arranged inside the device housing 1, and a heat-resistant brick is laid on the inner edge of the drying cavity 4 , The top of the device housing 1 is provided with a feed pipe 5, the device housing 1 is provided with an electric heating wire 2 at the bottom of the drying cavity 4, the drying cavity 4 is provided with a rotating shaft 6 and the rotating shaft 6 passes through the device The back of the housing 1 is connected to the outside world. A driven gear 7 is fixedly connected to the outer end of the rotating shaft 6, a rotating motor 3 is fixedly connected to one side of the device housing 1, and a driving gear is fixedly connected to the rotating shaft 6 of the rotating motor 3 8. The main gear and the driven gear 7 are connected by a chain 9. The end of the rotating shaft 6 inside the drying chamber 4 is fixedly c...

Embodiment 2

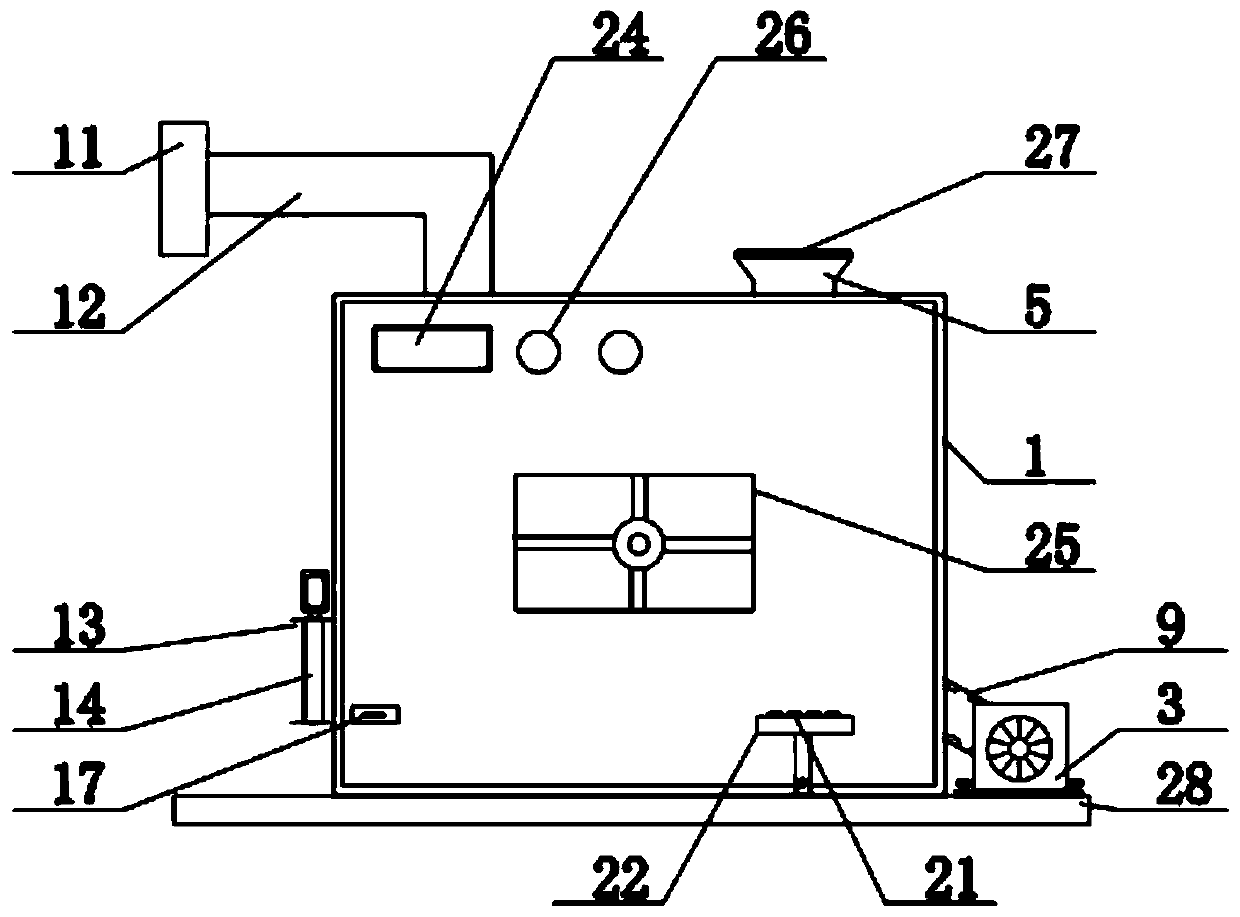

[0031] See figure 1 —5. A tartary buckwheat drying device, which is basically the same as the first embodiment, with further settings. The upper part of the device housing 1 is provided with a control cavity, the control housing 20 is installed in the control cavity, and the control housing 20 and the control A heat shield 23 is arranged between the cavities to prevent the high temperature generated by the operation of the device from affecting the inverter 19;

[0032] The device casing 1 is provided with a display screen 24 on the front side, and the display screen 24 is connected with the temperature sensor 18, so that the detected temperature can be displayed by the display screen 24 for the staff's reference. The device casing 1 is provided with an observation port 25 in the middle. Tempered glass is embedded in 25, and the observation port 25 is mainly used to observe the drying degree of tartary buckwheat inside the drying chamber 4;

[0033] The top of the feeding pipe 5 is...

Embodiment 3

[0041] See figure 1 —5. A tartary buckwheat drying device whose working principle is: when in use, add tartary buckwheat from the feed inlet to the inside of the drying cavity 4, when the addition is completed, close the lid 27, turn on the power, and pass The control knob controls the heating wire 2 to start heating. The heating wire 2 generates heat to dry the tartary buckwheat inside the drying cavity 4. At the same time, the rotating motor 3 is started, so that the driving gear 8 drives the driven gear 7 to rotate through the chain 9. Thus, the rotating shaft 6 and the stirring blade 10 are driven to rotate. The rotating stirring blade 10 continuously stirs the internal tartary buckwheat, so that the drying is sufficiently uniform, and the steam generated during the drying process is exhausted from the air by the fan 11 The pipe 12 is discharged, and the display 24 can always display the temperature data transmitted from the temperature sensor 18 during the drying process. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com