Underwater constructed water sealing layer monitoring device for vertical shaft

A technology for monitoring devices and water layers, applied in construction and other directions, to achieve the effect of ensuring one-time success rate and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

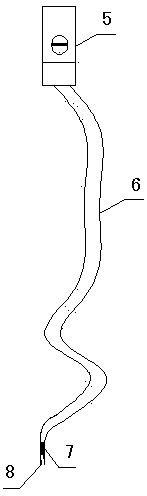

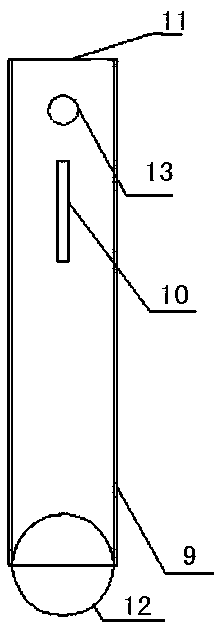

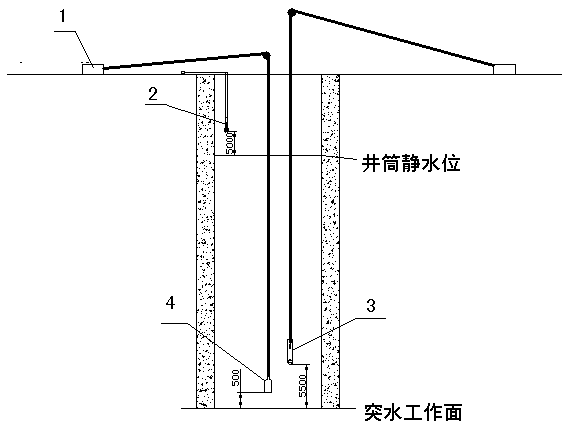

[0020] Embodiment 1: A vertical well underwater construction water sealing layer monitoring device, including a lifting device 1, a water level monitoring device 2, a slurry sampling device 3 and a deep well imager 4, there are several lifting devices, and the water level monitoring device includes a multimeter 5. Electric wire 6, insulating plate 7 and electrode tip 8, the electrode tip is installed on the insulating plate, one end of the electric wire is connected to the electrode tip through the insulating plate, and the other end is connected to the multimeter, and the slurry sampling device includes a tube body 9, The slurry inlet 10 and the sealing plate 11, the slurry inlet is arranged on the side wall of the pipe body, the sealing plate is connected with the pipe body, and there are several lifting devices connected with the deep well imager and the pipe body respectively.

Embodiment 2

[0021] The difference between embodiment 2 and embodiment 1 is that it also includes a solid sphere 12 and a suspension hole 13, the solid sphere is fixedly connected to the bottom of the pipe body, there is one sealing plate and the sealing plate is divided into two halves. It is connected to both sides of the top of the pipe body, at least half of which is movably connected to the top of the pipe body. The suspension hole is opened on the side wall of the pipe body and is located above the slurry inlet. One of the lifting devices is connected to the pipe body through the suspension hole.

[0022] Among the present invention, hoisting device can adopt the equipment such as stabilizing car, winch, winch etc. in the prior art. During the monitoring process of the water level monitoring device, when the electrode head touches the water surface, a loop is formed, and the number displayed by the multimeter changes at this time, and the water level in the wellbore can be calculated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com