A large-scale valve and large-diameter pipeline pre-spliced short connection manufacturing and hoisting method

A hoisting method and pre-assembled technology, applied in pipeline systems, welding equipment, manufacturing tools, etc., can solve problems such as difficult to guarantee quality, many hidden dangers in high-altitude operation, and long construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

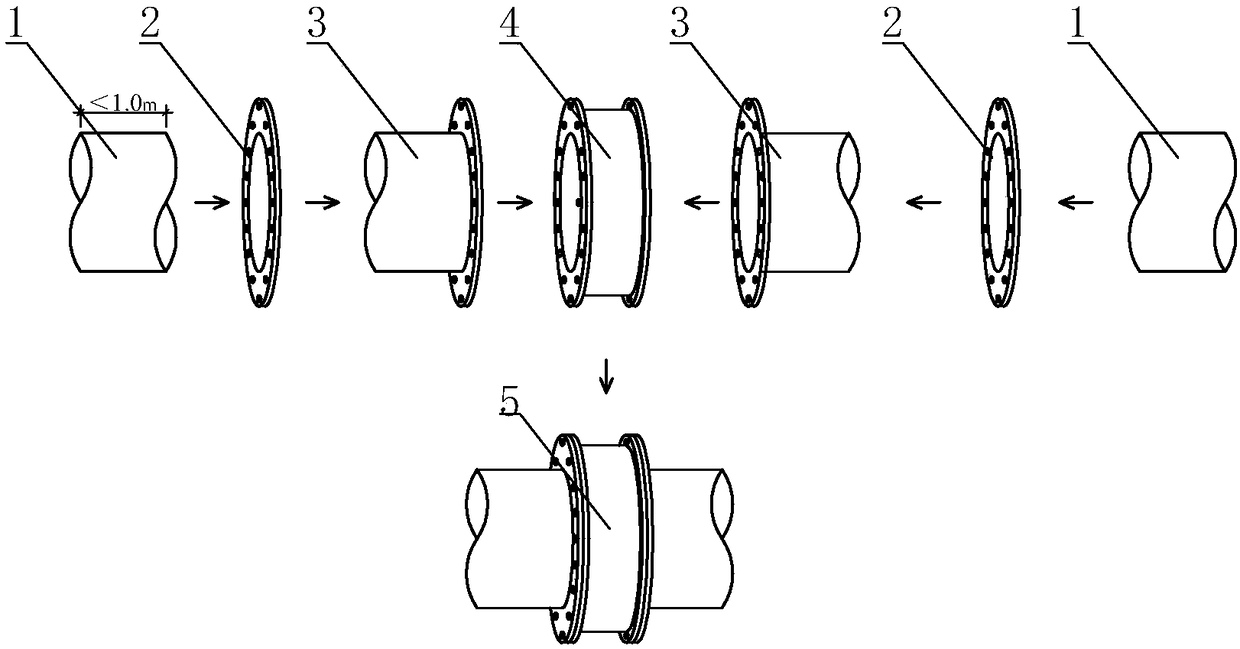

[0156] A large-scale valve and large-diameter pipeline pre-assembled short connection manufacturing and hoisting method, the manufacturing and hoisting method is to make a prefabricated section and a pre-assembled whole in a ground processing site, and then use a vertical transport machine to hoist the pre-assembled whole in place The method of butt welding with the installed overhead large-diameter pipeline;

[0157] Its technological process is:

[0158] Construction preparation→production of prefabricated section→production of pre-assembled whole→hoisting of pre-assembled whole→butt welding of pre-assembled whole and installed overhead pipeline→acceptance;

[0159] Specific steps include:

[0160] The first step, construction preparation

[0161] (1) Technical preparation

[0162] (1) Determine the short and large diameter pipeline prefabrication scheme based on the BIM model and pipeline single-line diagram, combined with the measured installation size, and adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com