Floating thread connection weaving method

A floating thread and yarn technology, which is applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of small friction coefficient of yarn surface and affect the weaving effect, so as to improve the sense of quality, enrich the contrast of texture and color, and apply wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

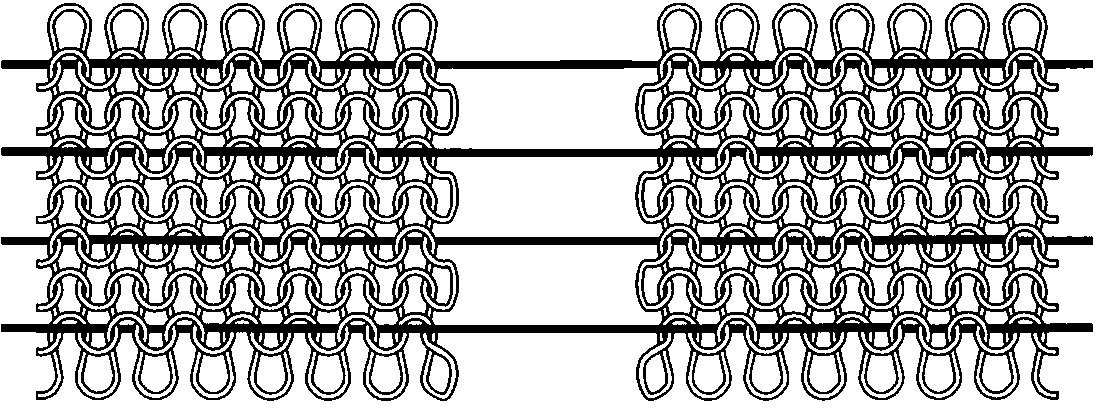

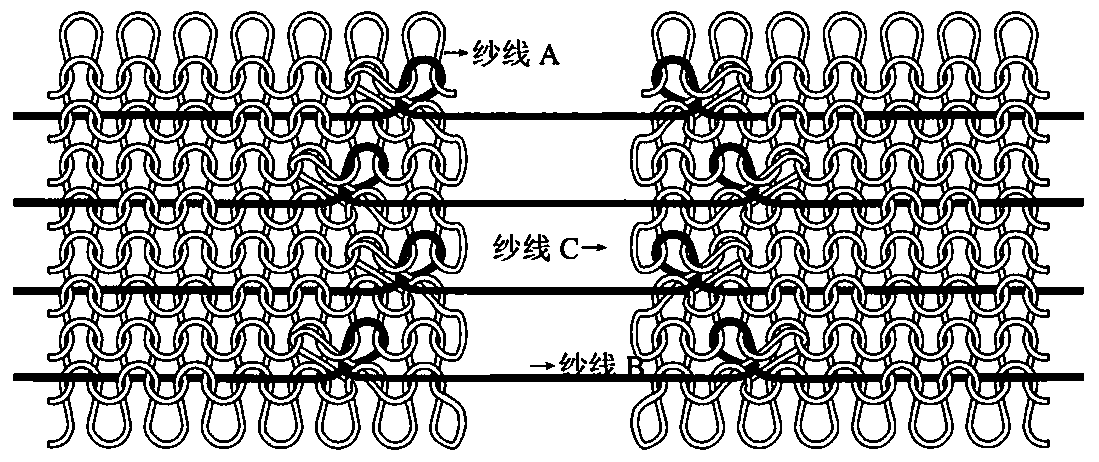

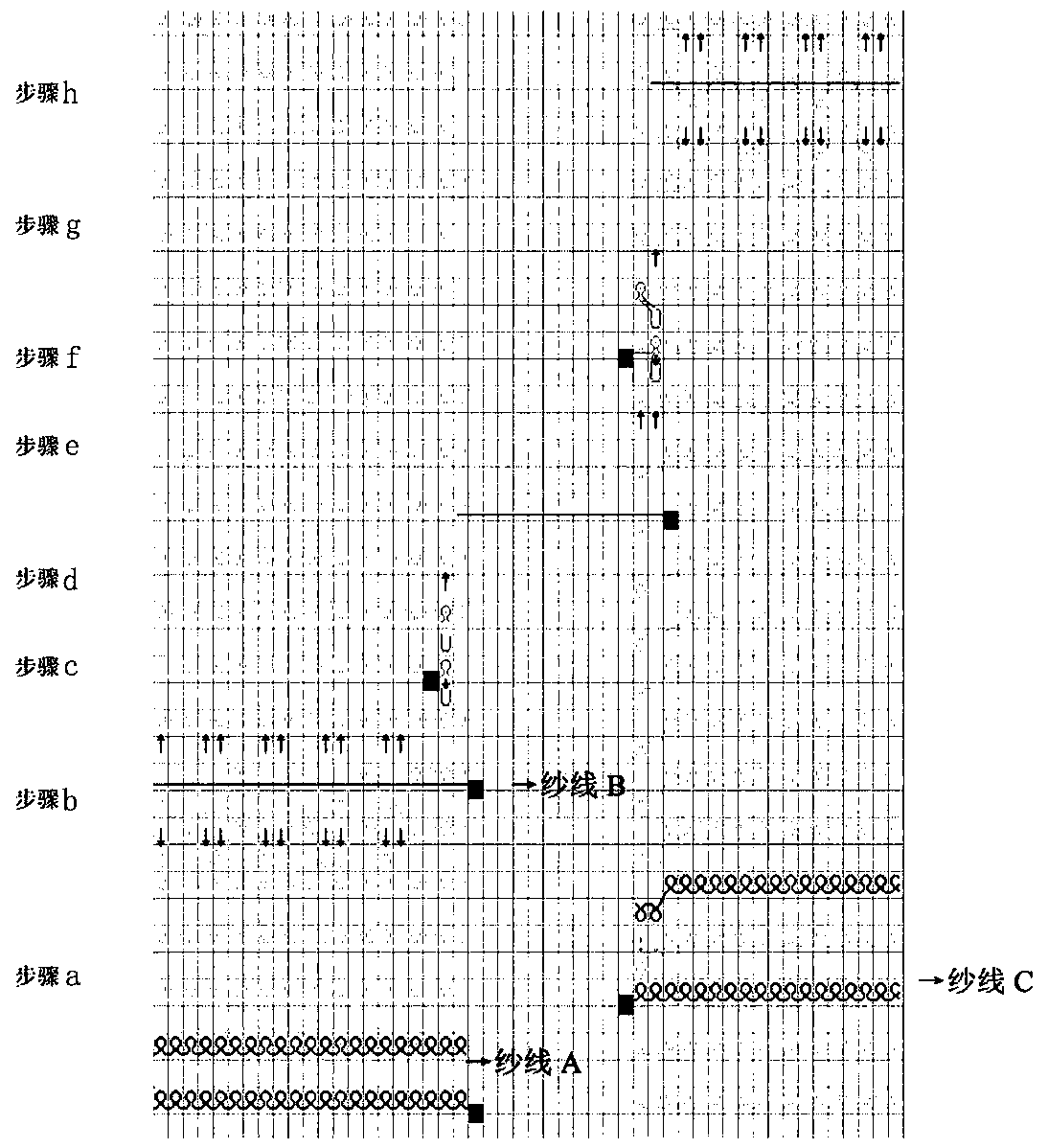

[0021] The floating line connection knitting method described in this embodiment, such as figure 2 As shown, a floating thread joint knitting method uses a flat knitting machine with a pair of front and rear needle beds extending in the left-right direction and facing each other in the front-back direction. The flat knitting machine feeds yarn A, yarn B, and yarn C For knitting, yarn A and yarn C are used to connect two different pattern knitting areas through yarn B. At the same time, yarn B is twisted into a loop knitting at the connecting part, and the minute needle moves to form a floating line connection structure. The above knitting method is divided into when the yarn B is left and when the yarn B is right when weaving, it specifically includes the following steps:

[0022] Such as image 3 As shown, (1) When yarn B runs to the left:

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com