A kind of aluminum alloy U-shaped frame profile for aerospace and preparation method thereof

An aluminum alloy and U-shaped technology, which is applied in the field of aerospace aluminum alloy U-shaped frame profiles and their preparation, can solve the problems of uneven manual processing area, uneven bending radian, low production efficiency, etc., and achieve strong practical strengthening effect. , Improve the accuracy and the effect of good plane flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

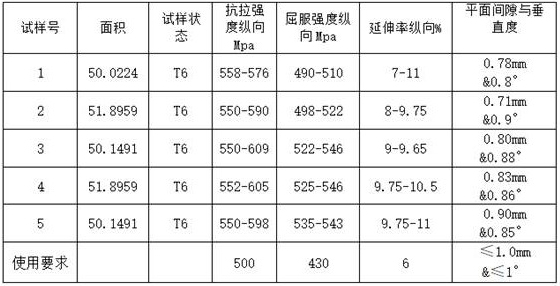

Examples

Embodiment 1

[0028] An aluminum alloy U-shaped frame profile for aerospace, which is composed of the following elements in weight percentage: Zn5.6%, Cu2.4%, Mn<0.1%, Mg1.8%, Cr0.25%, Fe0.25%, Si≤0.1%, Ti<0.08%, and the balance is Al.

[0029] The preparation method of the aluminum alloy U-shaped frame profile for aerospace comprises the following steps:

[0030] (1) Select remelted aluminum ingots, zinc ingots, magnesium ingots, electrolytic copper plates, Al-4Cr alloys, and Al-10Fe alloys with a grade ≥99.85% as raw materials according to the composition of elements;

[0031] (2) Use a resistance reverberatory furnace to melt remelted aluminum ingots, Al-4Cr alloys, and Al-10Fe alloys at 700 ° C. After melting, add zinc ingots, magnesium ingots and electrolytic copper plates into the melt, and stir and melt to form an alloy melt;

[0032] (3) Use nitrogen-chlorine mixed gas blowing method to purify the melt, and the ratio of nitrogen-chlorine mixed gas is N 2 =84%, Cl 2 =16%, blowing ...

Embodiment 2

[0040] An aluminum alloy U-shaped frame profile for aerospace, which is composed of the following elements in weight percentage: Zn6.0%, Cu2.0%, Mn<0.1%, Mg2.2%, Cr0.22%, Fe0.30%, Si≤0.1%, Ti<0.08%, and the balance is Al.

[0041] The preparation method of the aluminum alloy U-shaped frame profile for aerospace comprises the following steps:

[0042] (1) Select remelted aluminum ingots, zinc ingots, magnesium ingots, electrolytic copper plates, Al-4Cr alloys, and Al-10Fe alloys with a grade ≥99.85% as raw materials according to the composition of elements;

[0043] (2) Use a resistance reverberatory furnace to melt remelted aluminum ingots, Al-4Cr alloys, and Al-10Fe alloys at 760 ° C. After melting, add zinc ingots, magnesium ingots and electrolytic copper plates into the melt, and stir and melt to form an alloy melt;

[0044] (3) Use nitrogen-chlorine mixed gas blowing method to purify the melt, and the ratio of nitrogen-chlorine mixed gas is N 2 =84%, Cl 2 =16%, blowing ...

Embodiment 3

[0052] An aluminum alloy U-shaped frame profile for aerospace, which is composed of the following elements in weight percentage: Zn6.5%, Cu1.4%, Mn<0.1%, Mg2.6%, Cr0.2%, Fe0.35%, Si≤0.1%, Ti<0.08%, and the balance is Al.

[0053] The preparation method of the aluminum alloy U-shaped frame profile for aerospace comprises the following steps:

[0054] (1) Select remelted aluminum ingots, zinc ingots, magnesium ingots, electrolytic copper plates, Al-4Cr alloys, and Al-10Fe alloys with a grade ≥99.85% as raw materials according to the composition of elements;

[0055] (2) Use a resistance reverberatory furnace to melt remelted aluminum ingots, Al-4Cr alloys, and Al-10Fe alloys at 730°C. After melting, add zinc ingots, magnesium ingots, and electrolytic copper plates into the melt, and stir and melt to form an alloy melt;

[0056] (3) Use nitrogen-chlorine mixed gas blowing method to purify the melt, and the ratio of nitrogen-chlorine mixed gas is N 2 =84%, Cl 2 =16%, the blowin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com