Phase-transition temperature adjustable composite phase-change material

A composite phase-change material and phase-change temperature technology, which is applied in the field of phase-change energy storage, can solve the problems of complex and economical selection of phase-change materials, and achieve the effects of reducing cumbersome steps in material selection, low price, and strong economy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

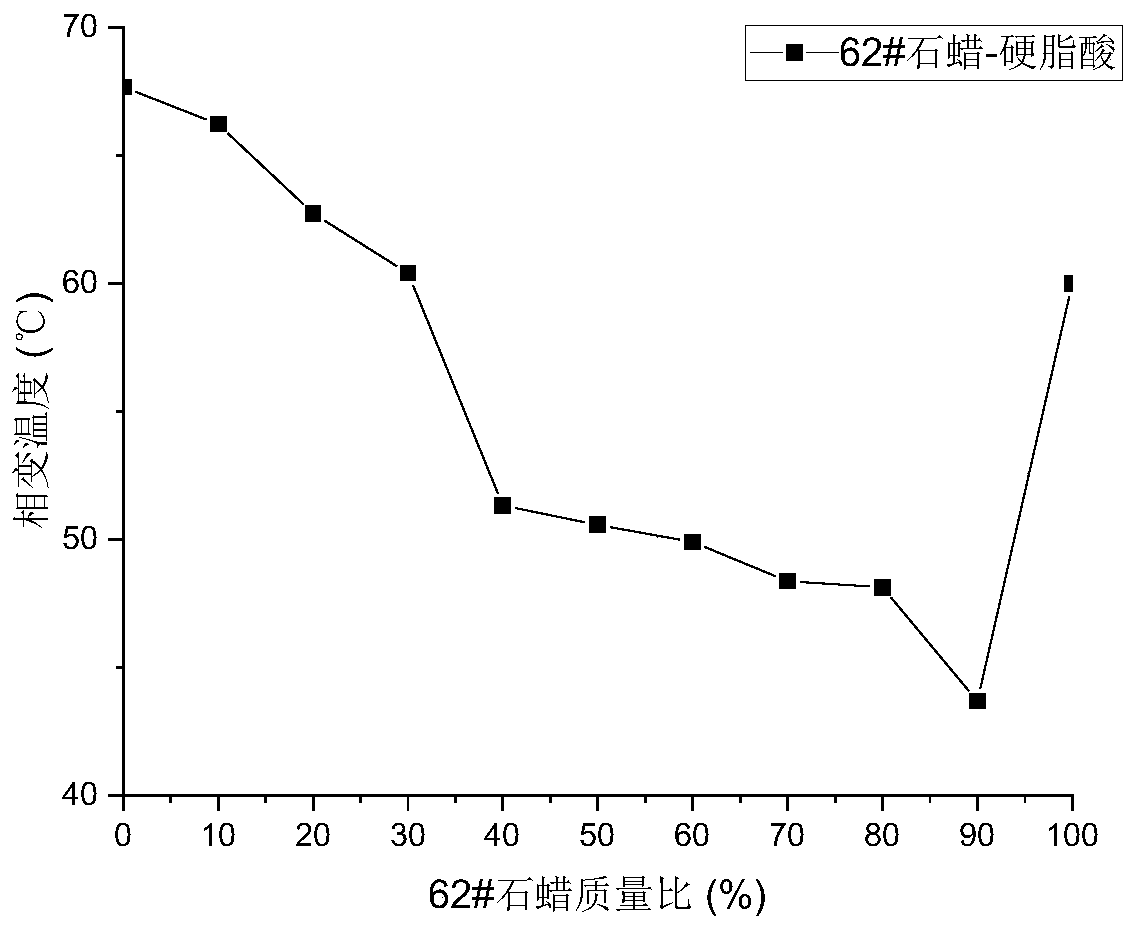

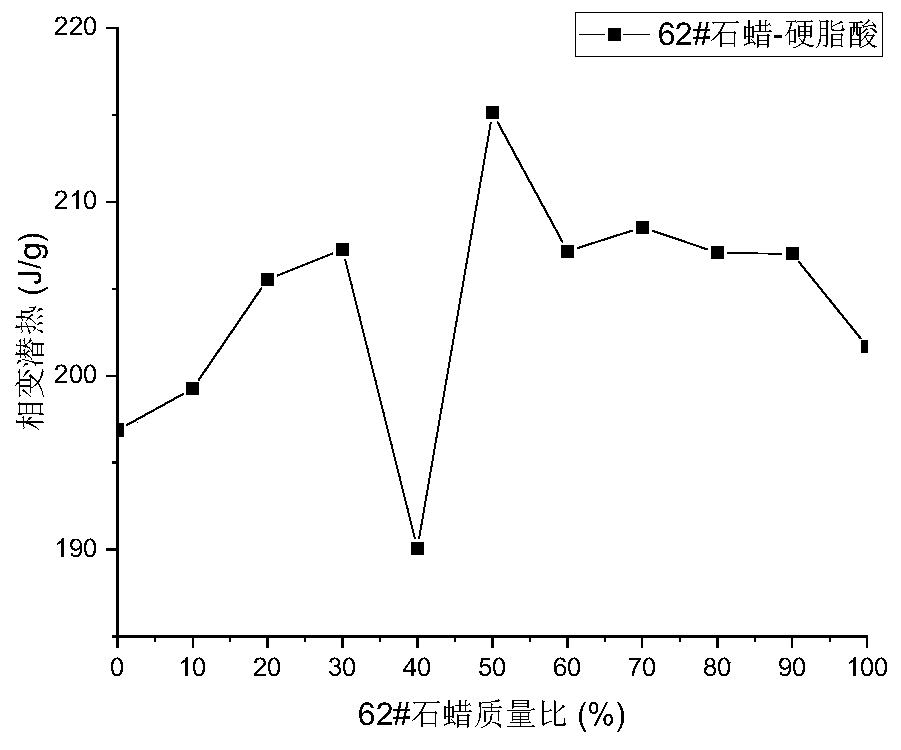

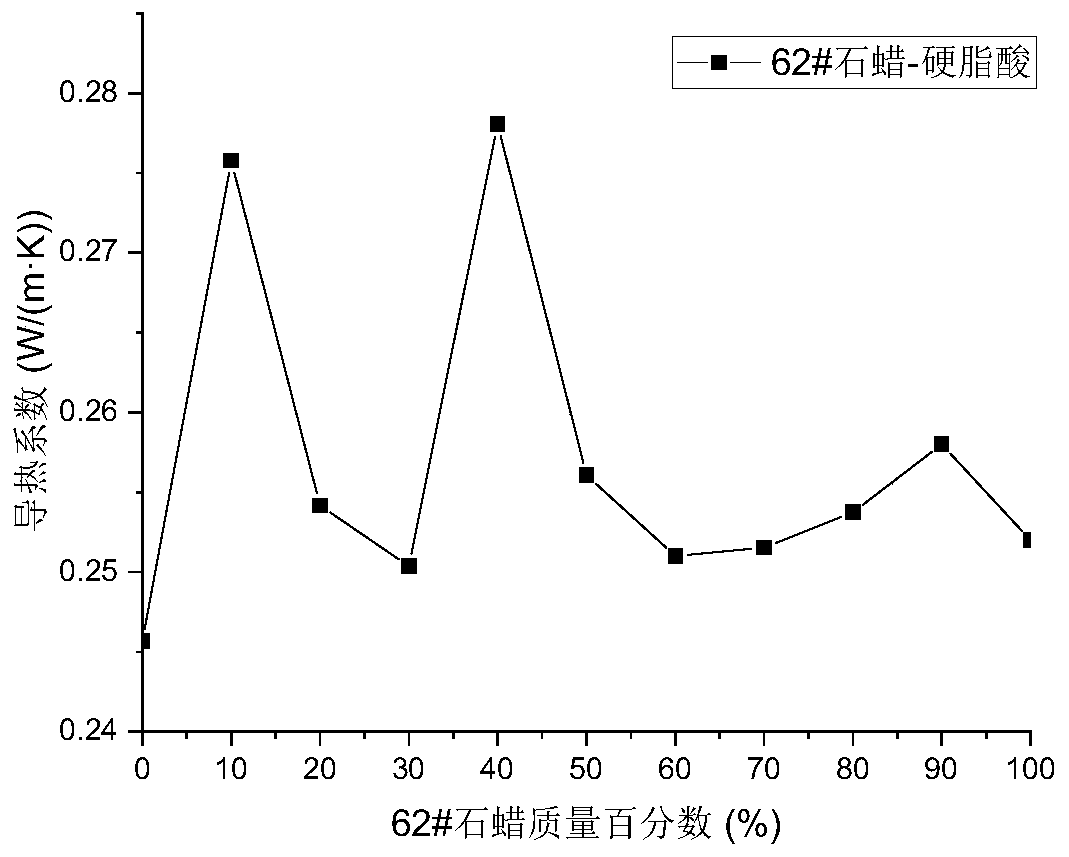

[0026] The fatty acid used in the composite phase change material with adjustable phase change temperature in the embodiment of the present invention is stearic acid, by changing the ratio of 62# paraffin wax and stearic acid, the experiment of phase change temperature is carried out, adopting thermal analysis method (Differential Scanning Calorimeter, DSC) tests the phase change temperature and latent heat of phase change of the composite phase change material. Through the analysis software, the initial point is used as the phase change temperature of the sample, and the area is used as the latent heat of phase change, and the thermal conductivity tester is used to test the composite phase change material The thermal conductivity is measured, and its specific ratio and results are shown in Table 1 below, and the corresponding test results are as follows figure 1 , figure 2 and image 3 shown.

[0027] Table 1

[0028]

[0029] Specific steps: according to the above mas...

Embodiment 2

[0036] The second embodiment provides a composite phase change material using graphite, 62# paraffin and stearic acid as raw materials. In this example, a composite phase change material with a ratio of 62# paraffin wax to stearic acid of 2:8 is used, the phase change temperature is 62.73°C, the latent heat of phase change is 205.53J / g, and the thermal conductivity is 0.254W / (m·K ). Experiments were carried out by adding different graphite ratios to the composite material at this ratio, and the specific ratios and results are shown in Table 2 below.

[0037] Table 2

[0038]

[0039] The composite phase-change material (the ratio of 62# paraffin wax to stearic acid is 2:8) and graphite are weighed with a balance according to the above-mentioned mass ratio, then put into a beaker, and irradiated with an infrared lamp. After the sample is melted, , stirring and shaking until the mixture is uniform, then the infrared lamp is removed, and the graphite-added composite phase ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com