Method for preparing composite phase change energy storage material and phase change material

An energy storage material and composite phase change technology, applied in the field of materials, can solve the problems of high subcooling, less than 20% cold chain circulation rate, insufficient cold chain transportation capacity, etc., and achieve the effect of improving the phase change performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention researches and prepares a composite phase-change energy storage material for low-temperature transportation and storage of fruit, and adjusts the phase-change temperature through different proportions of the composite material, so that it can be applied to different fruits.

[0051] The invention combines the selection requirements of the phase change energy storage material to select a phase change energy storage material suitable for fruit transportation and storage. And the selected phase change energy storage material is improved to obtain a phase change energy storage material with more excellent performance. The main research contents of the present invention include:

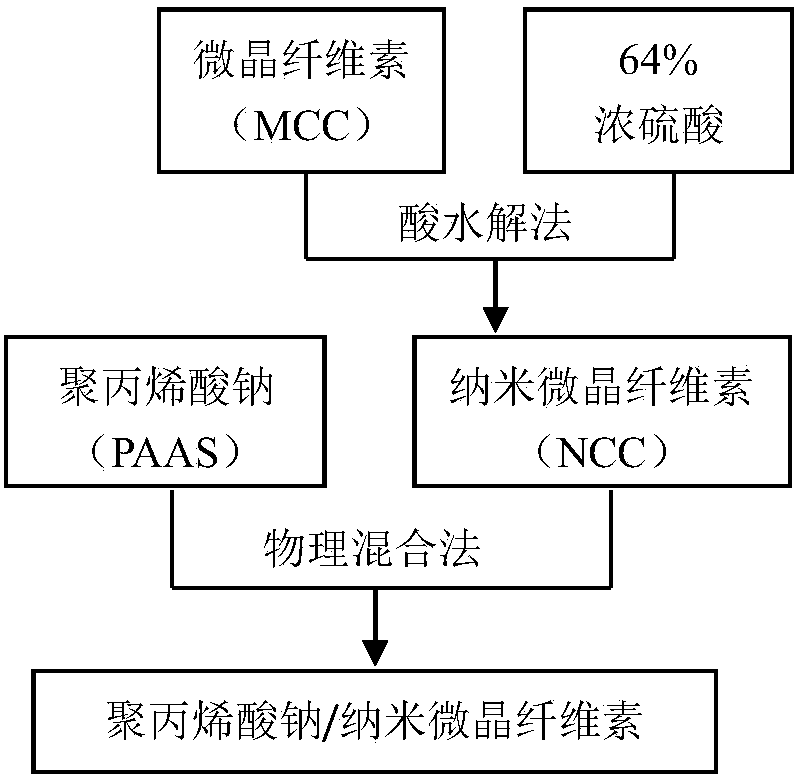

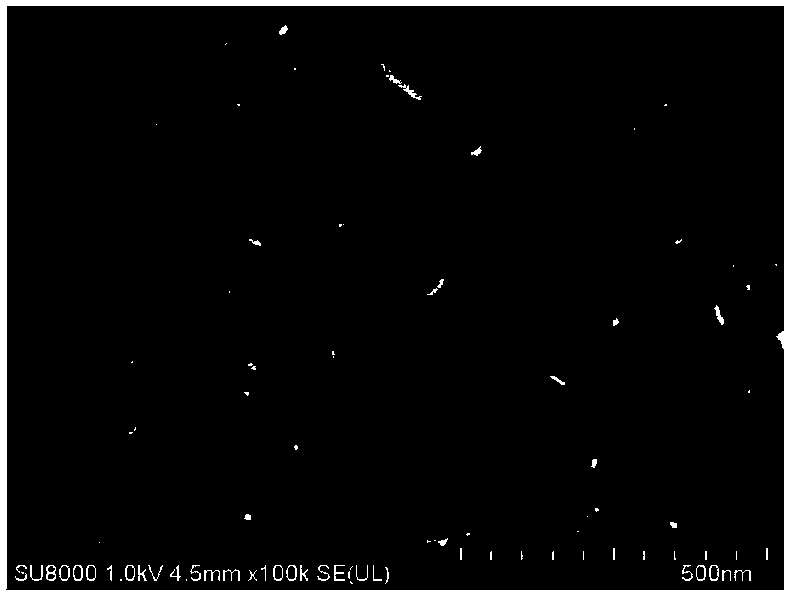

[0052] (1) According to the temperature requirements of fruit transportation and storage, comparative analysis of calcium chloride hexahydrate (CaCl 2 ·6H 2 O), sodium sulfate decahydrate (Na 2 SO 4 10H 2 O), octanoic acid (C 8 h 16 o 2 ), sodium polyacrylate (PAAS) hydrogel, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Latent heat of phase change | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com