Liquid-phase synthesis method of semaglutide side chain

A liquid-phase synthesis and side-chain technology, which is applied in the field of liquid-phase synthesis of semaglutide side-chains, can solve the problem of not finding a pure liquid-phase synthesis method for the side-chain, and achieves easy control of the reaction process, simple production process, and easy process. workable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

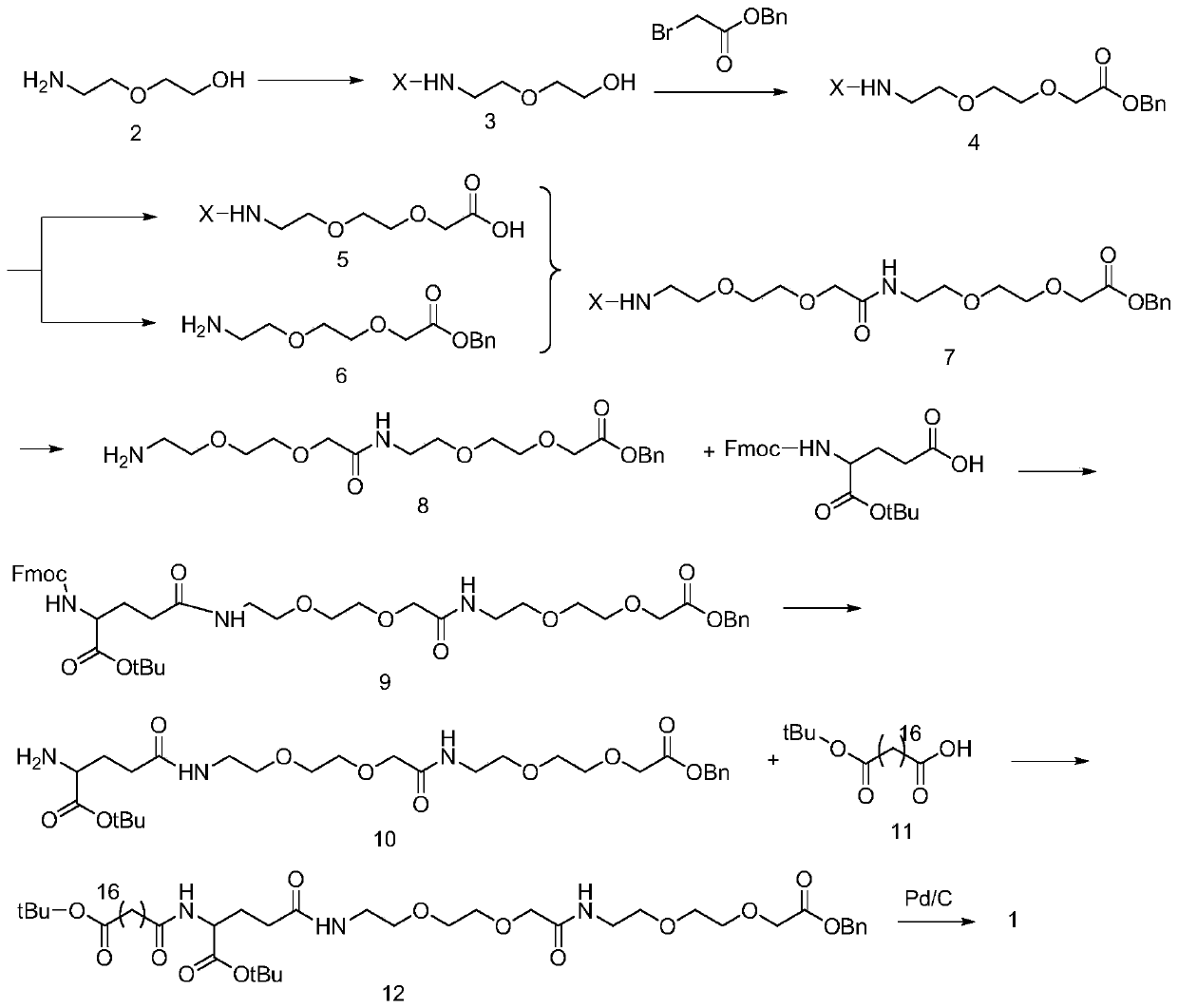

[0058] according to figure 1 The synthetic route shown carries out the liquid phase synthesis of the side chain of semaglutide:

[0059] a. Preparation process of compound 3

[0060] Dissolve 1.05g of compound 2 (10mmol) in 50ml of DCM solution, place it in a nitrogen-protected flask, and carefully add (Boc) 2 O (2.62 g, 12 mmol). The mixture was stirred for 12 hours, then the crude material was concentrated in vacuo. Purification by flash column chromatography gave a colorless oil in 95% yield.

[0061] b. The preparation process of compound 4:

[0062] Add 3.08g (9.5mmol) of compound 3, 8.6g (4eq) of benzyl bromoacetate and 2.75g (2.1eq) of potassium carbonate into a round-bottomed flask. Relatively complete; washed with water, extracted 2-3 times with EA, washed with saturated brine, anhydrous Na 2 SO 4 After drying, P:E=6:1, the product was collected and the yield was 85%.

[0063] c. The preparation process of compound 5:

[0064] Dissolve 1.412g (4mmol) of compo...

Embodiment 2

[0081] a. Preparation process of compound 3

[0082]Dissolve 5mmol / ml compound 2 (1ml) in DCM solution, place it in a nitrogen-protected flask, and after the above mixture drops to 0°C, add 1eq of Et dropwise 3 N; After 20 minutes, slowly add 2mmol / ml Trt-Cl (2.5ml) mixture to the above mixture, and remove the ice bath after 10 minutes; stir at room temperature, observe on the plate after 1h, the reaction is complete . Wash with water, extract with DCM 2-3 times, wash with saturated brine, anhydrous Na 2 SO 4 After drying, P:E=5:1, the product was collected and the yield was 85%.

[0083] b. The preparation process of compound 4:

[0084] Add 694mg (2mmol) of compound 3, 1832mg (4eq) of benzyl bromoacetate and 580mg (2.1eq) of potassium carbonate into a round-bottomed flask, and raise the reaction temperature to 50°C. After reacting for 18 hours, spot the plate and observe that the reaction is relatively complete; wash with water , EA extracted 2-3 times, washed with satu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com