Feeding system for polyester slices

A feeding system, polyester chip technology, applied in conveyor objects, dryers, conveyors, etc., can solve the problem of poor uniformity of polyester melt, serious sticking of spinning spinnerets, and spinning components. Life shortening and other problems, to achieve the effect of improving uniformity, reducing sticking, and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

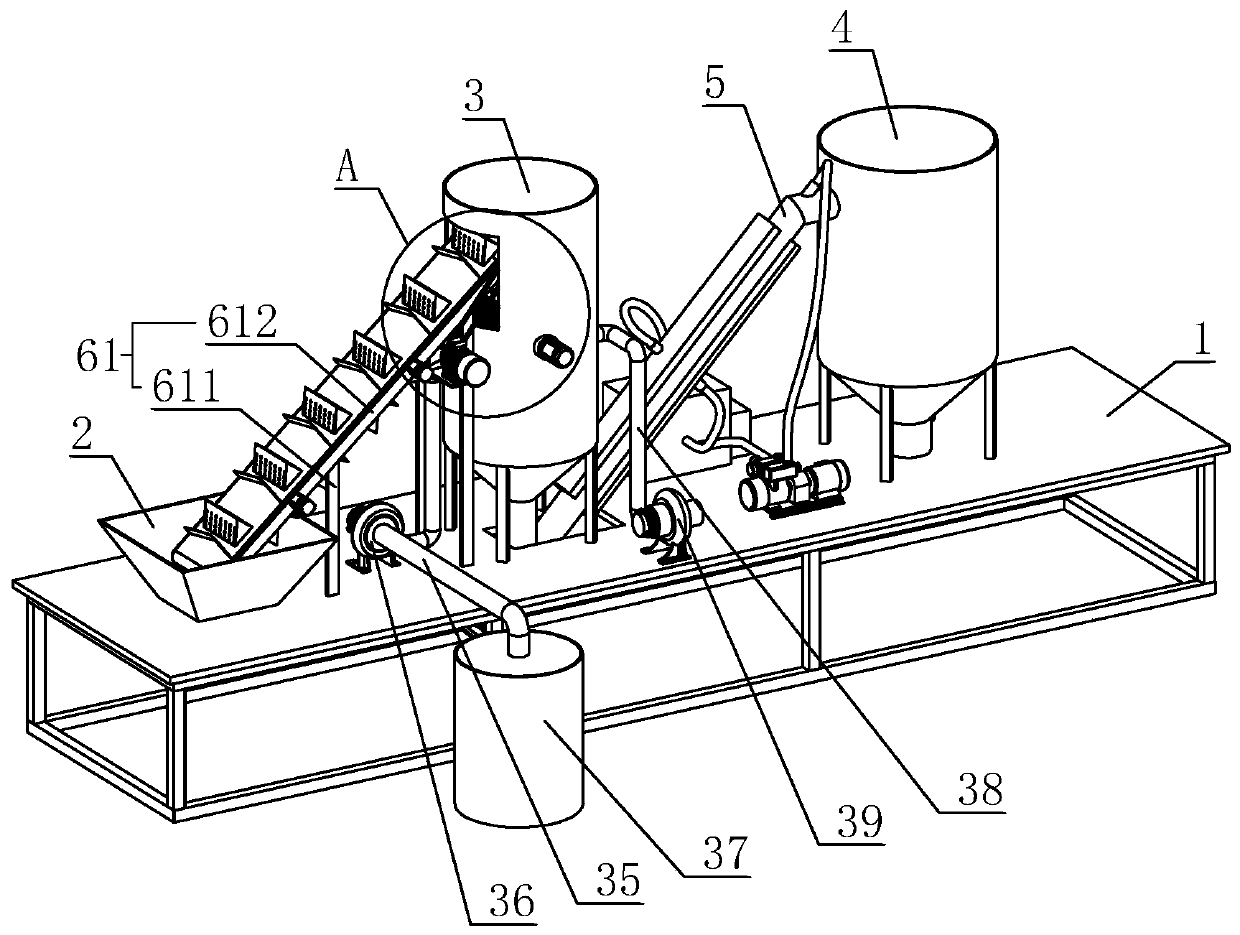

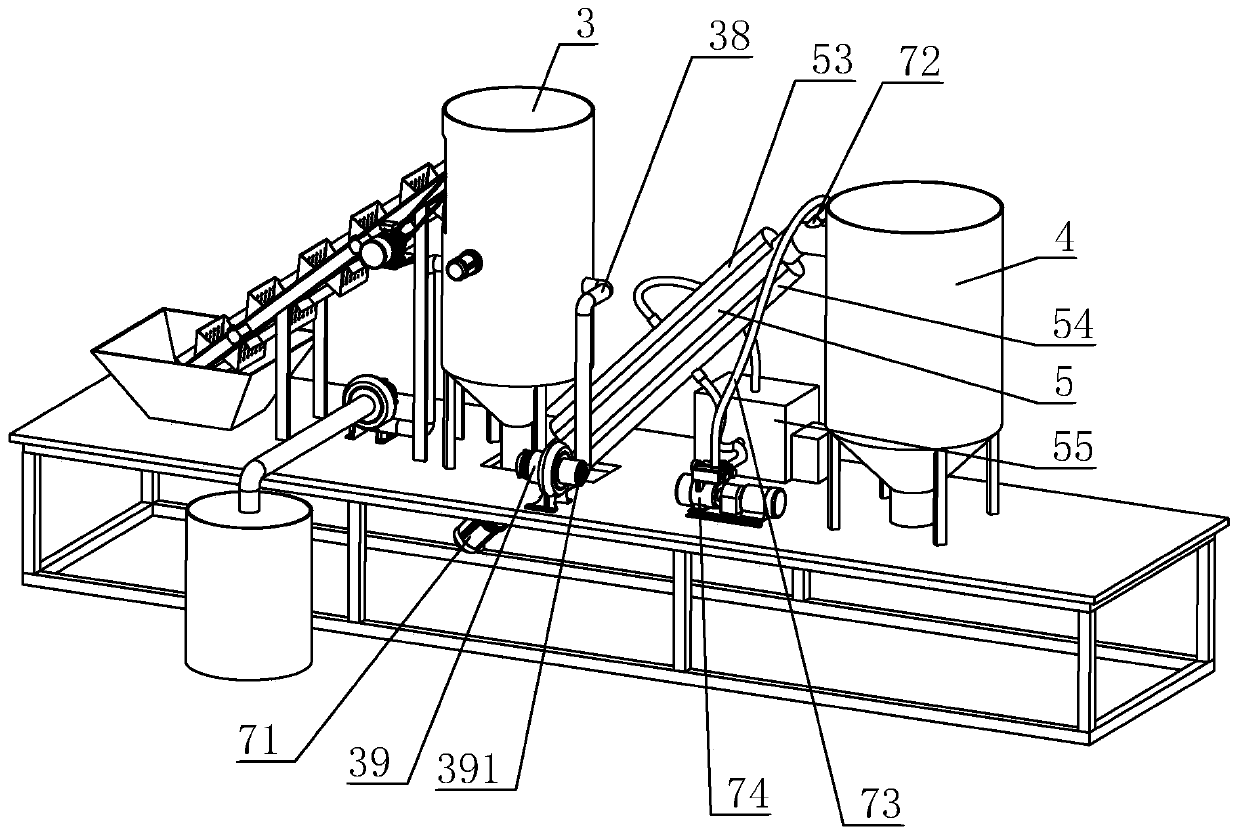

[0037] A feeding system for polyester chips, refer to figure 1 , comprising a frame 1, the frame 1 is fixedly provided with a discharge hopper 2, a charging box 3 and a drying box 4 connected in sequence, the discharging hopper 2 and the charging box 3 are connected by a feeding mechanism arranged on the frame 1, and the charging box 3 It is connected with the drying box 4 through the crystallization tube 5 arranged at an angle.

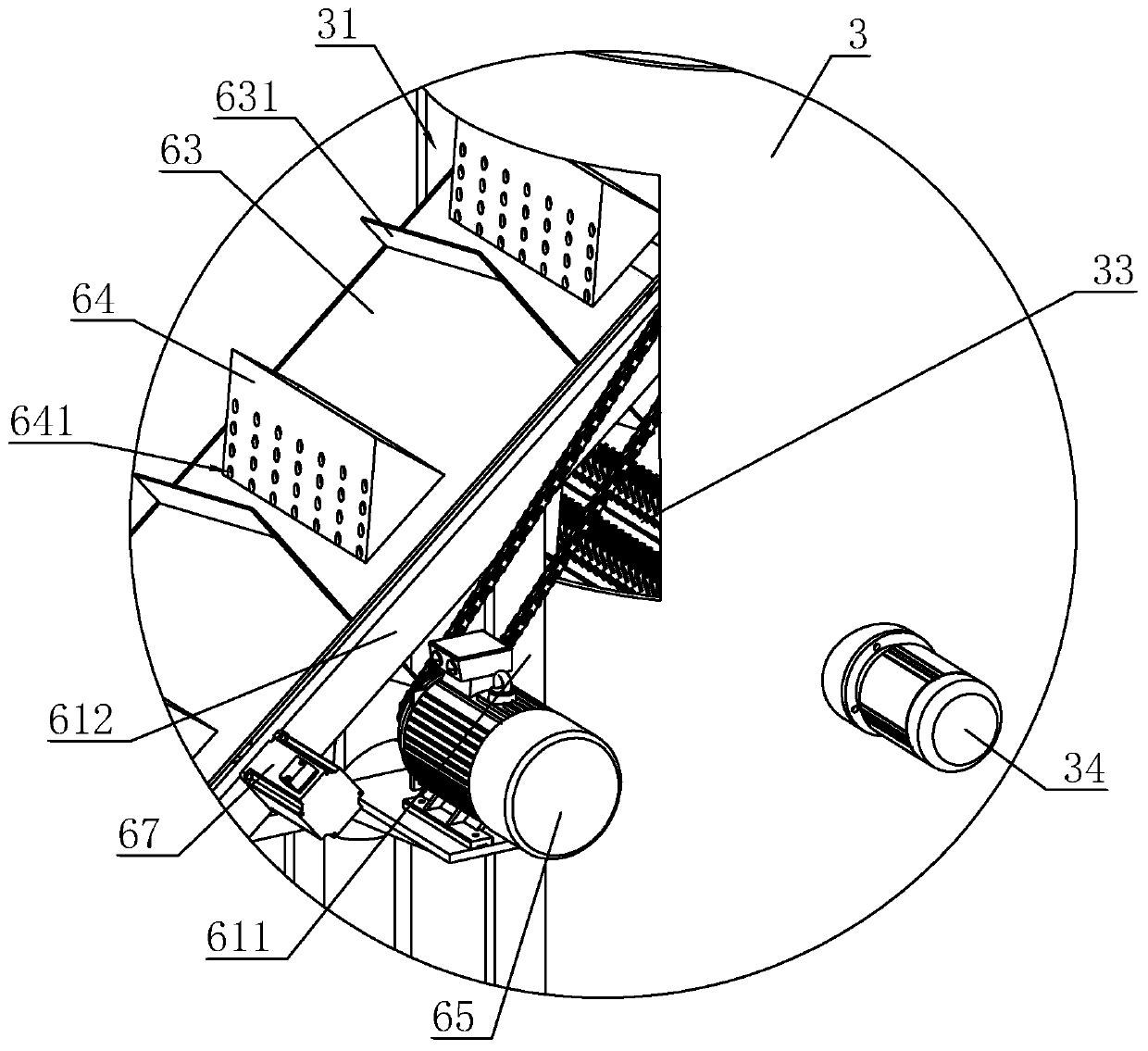

[0038] refer to figure 1 with figure 2 , the upper end of the feeding box 3 and the side wall facing the discharge hopper 2 are provided with a feed inlet 31, and the feeding mechanism includes a connecting frame 61, a conveying wheel (not shown in the figure), a conveyor belt 63, a hopper 64 and a feeding motor 65, and the connecting frame 61 includes a bottom frame 611 fixed on the frame 1 and located between the discharge hop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com