Pressure-resisting welding method for circular seam of pressure container

The technology of a pressure vessel and a welding method, which is applied in the field of industrial manufacturing, can solve the problems of low welding efficiency, low production efficiency, and increase the number of weld repairs, and achieve the effect of convenient use and perfect method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

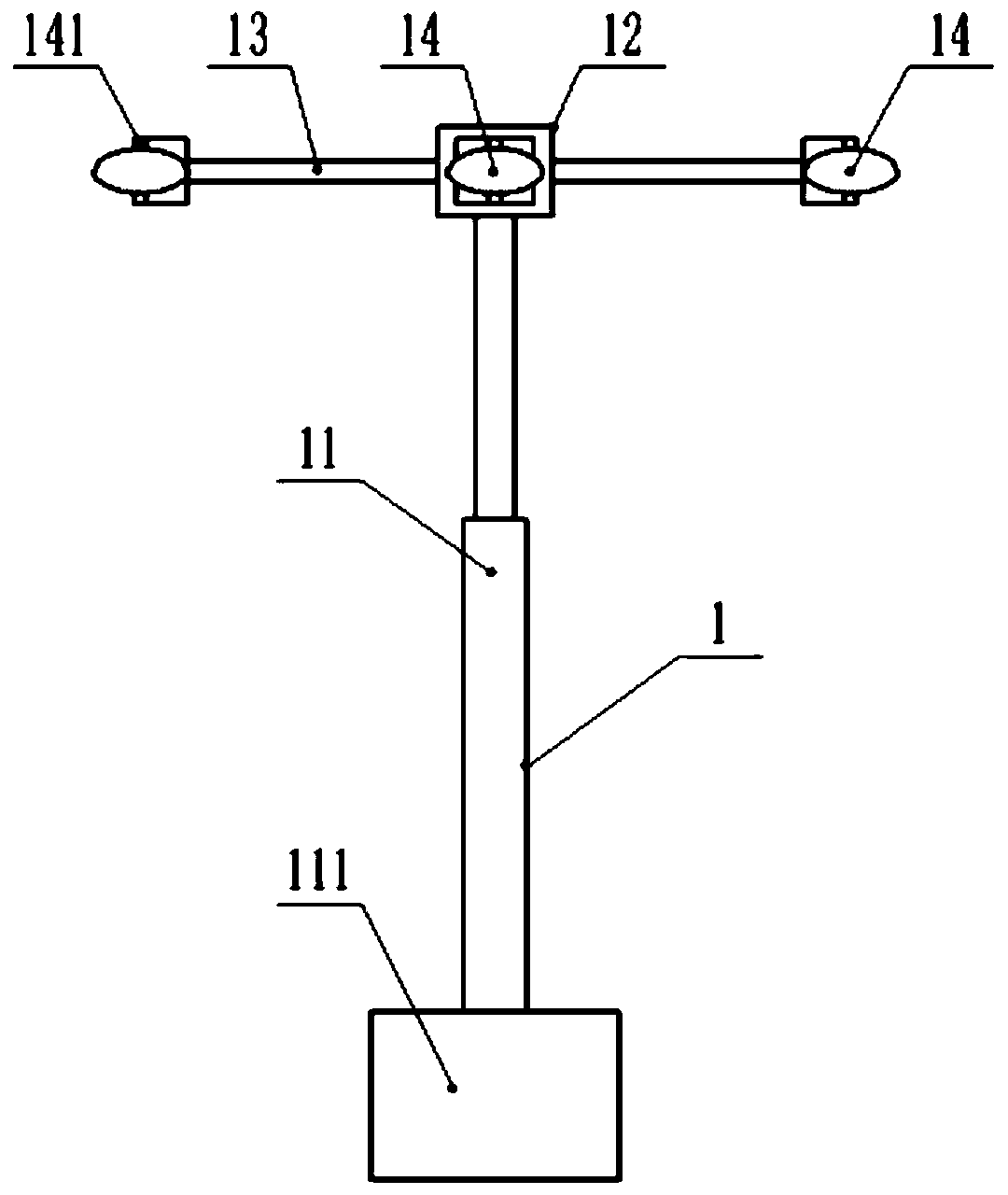

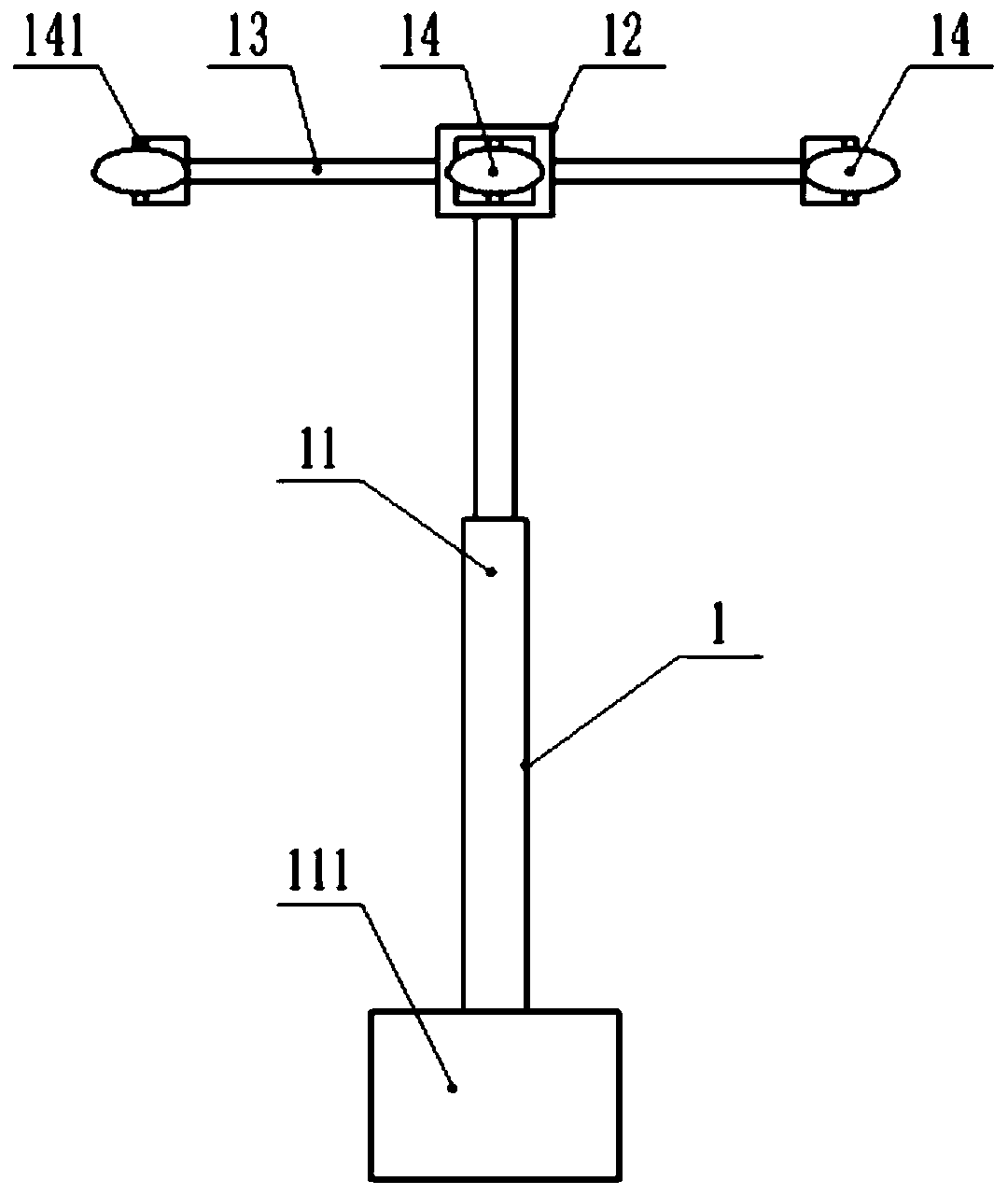

[0027] Embodiment 1: A pressure-resistant welding method for a pressure vessel girth, mainly comprising the following steps:

[0028] Step 1: pre-welding pretreatment

[0029] The pressure vessel cylinder after longitudinal seam welding is cooled and becomes round, and the pressure vessel cylinder is assembled on the supporting rotating frame 1, and the four support rods 13 supporting the rotating frame 1 are adjusted so that the rollers 14 at the front ends of the supporting rods 13 are in line with the The inner wall of the pressure vessel cylinder is in contact, and the plug-in interface is equidistantly drilled on both sides of the fixed pressure vessel cylinder, and the two ends of the pressure vessel cylinder and the connecting end of the pressure vessel head are beveled with a milling machine. Both the outer groove of the head and the pressure vessel cylinder are V-shaped grooves, and the pressure vessel head and the inner groove of the pressure vessel cylinder are both...

Embodiment 2

[0038] Embodiment 2: A pressure-resistant welding method for a pressure vessel girth, mainly comprising the following steps:

[0039] Step 1: pre-welding pretreatment

[0040] The pressure vessel cylinder after longitudinal seam welding is cooled and becomes round, and the pressure vessel cylinder is assembled on the supporting rotating frame 1, and the four support rods 13 supporting the rotating frame 1 are adjusted so that the rollers 14 at the front ends of the supporting rods 13 are in line with the The inner wall of the pressure vessel cylinder is in contact, and the plug-in interface is equidistantly drilled on both sides of the fixed pressure vessel cylinder, and the two ends of the pressure vessel cylinder and the connecting end of the pressure vessel head are beveled with a milling machine. The outer grooves of the head and the pressure vessel cylinder are V-shaped grooves, and the groove angle of the V-shaped groove is 68°. The pressure vessel head and the inner gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com