Carbon-based catalyst regeneration device and process

A carbon-based catalyst and regeneration device technology, applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve the effect of promoting heat exchange and reaction, improving distribution and flow state, and reducing physical loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following describes the substantive content of the present invention in detail in conjunction with the drawings and embodiments, but does not limit the protection scope of the present invention.

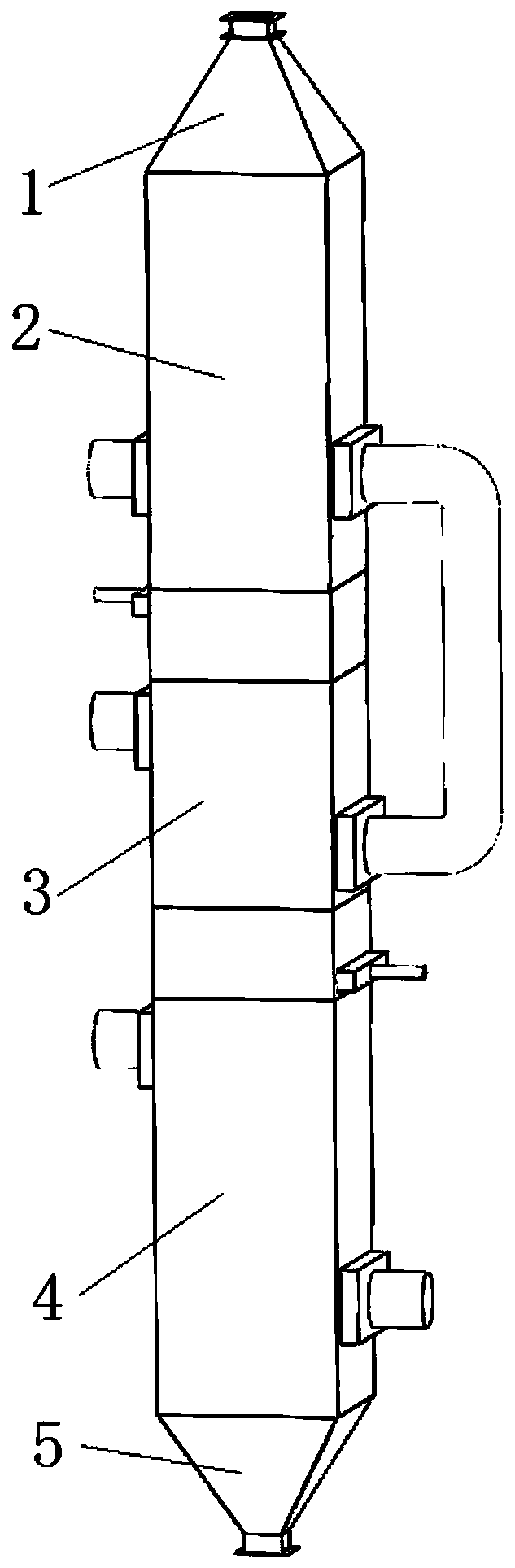

[0037] like figure 1 As shown, the top of the carbon-based catalyst regeneration device is the inlet 1, and the bottom is the outlet 5. From the inlet 1 to the outlet 5, there are desorption section 2, drying section 3 and recovery section 4 in sequence.

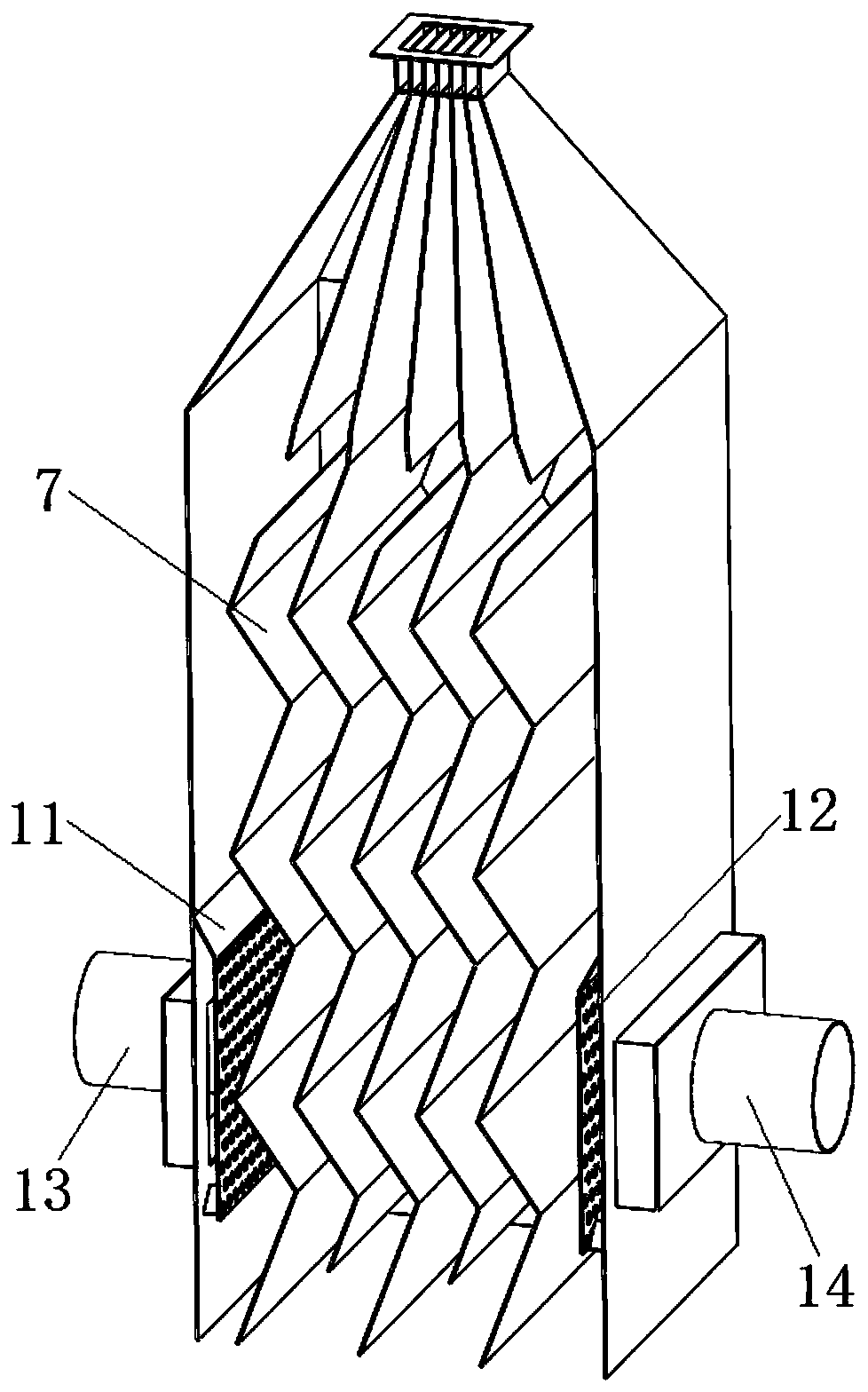

[0038] like figure 2 and Image 6 As shown, the inlet 1 has a built-in partition plate 6, including multiple inlet partitions 26 that divide the entrance of the inlet 1 into multiple inlet zones, and are used to transport the materials entering the inlet zone to the desorption section. 2 multi-block transition section partitions 27. In addition, the smaller angle between the separator 27 and the horizontal plane in the transition section is larger than the angle of repose of the carbon-based catalyst, which can make ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com