A quenching mixer for hydrogenation reactor

A technology of hydrogenation reactor and mixer, which is applied in the directions of fluid mixer, mixer, chemical instrument and method, can solve the problems of large flow resistance and poor mixing effect of the mixture flow, and achieve the enhanced cyclone mixing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

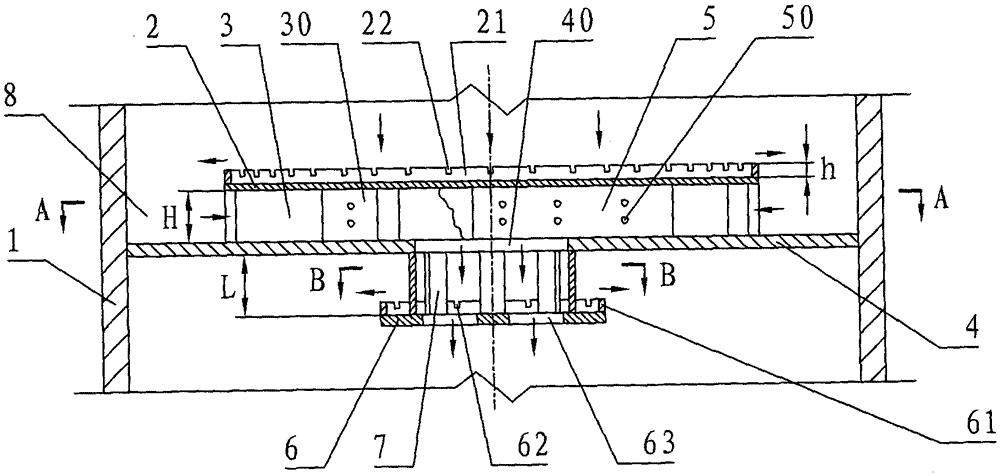

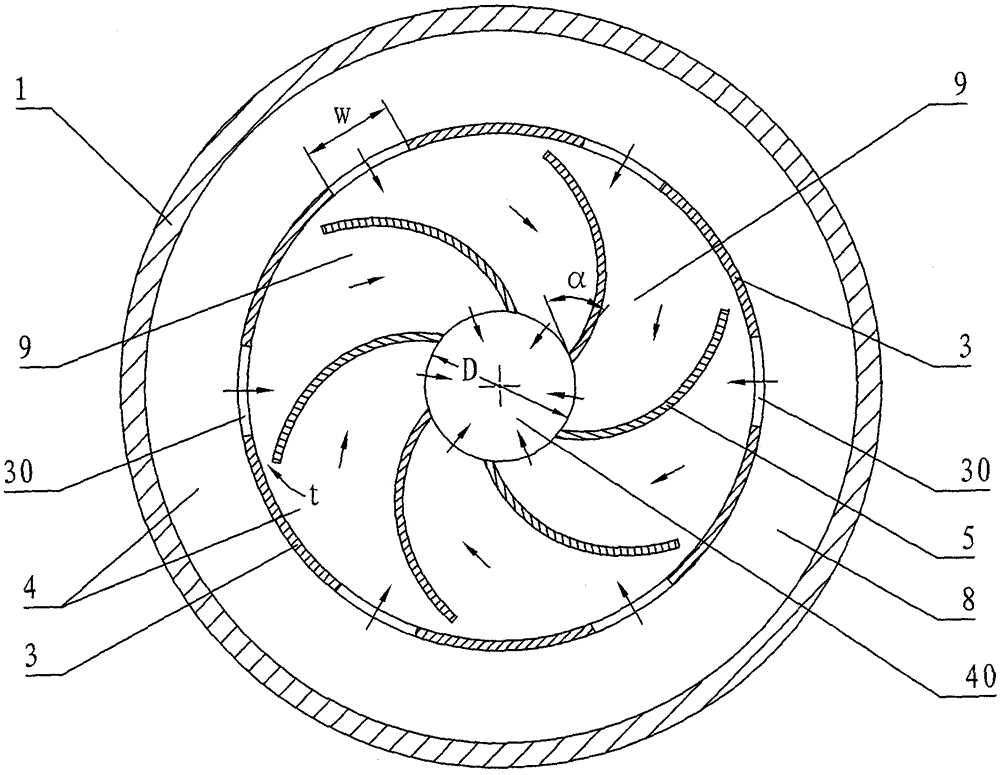

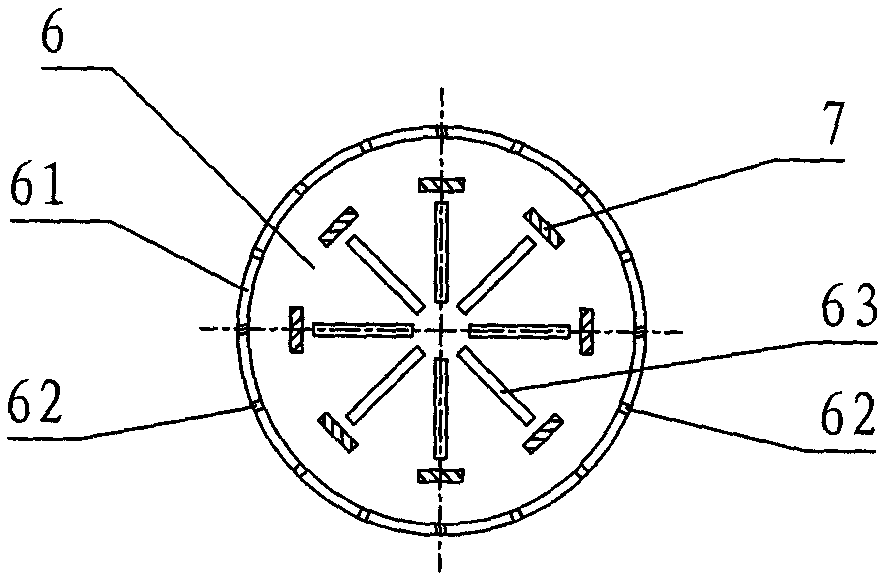

[0013] see figure 1 , figure 2 , the present invention is used in the quench mixer of the hydrogenation reactor (abbreviated as the quench mixer or mixer), provided with the swirl plate 5 . The top of the swirl plate 5 is connected with the top baffle plate 2 , and the bottom of the swirl plate 5 is connected with the interceptor plate 4 . A central hole 40 is provided at the center of the cutoff plate 4 , a distribution plate 6 is provided below the central hole 40 , and a distribution plate slit 63 is provided on the distribution plate 6 . The distribution plate 6 is fixed on the cut-off plate 4 through the connecting rib 7 . Between the top baffle 2 and the cut-off plate 4, at least four circular arc plates 3 are uniformly arranged around the edge of the top baffle 2 and at the outer end of the swirl plate 5, and a circular arc plate 3 is formed between two adjacent circular arc plates 3. The mixture flows into port 30 . The top baffle 2 and the cutoff plate 4 are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com