Efficient cobalt diselenide/cobalt tungstate composite electrocatalyst and preparation method thereof

A technology of cobalt diselenide and electrocatalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of low activity of a single cobalt tungstate catalyst, and improve the effective specific surface area, The effect of high yield and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] In the present embodiment, the synthesis process of cobalt tungstate is as follows:

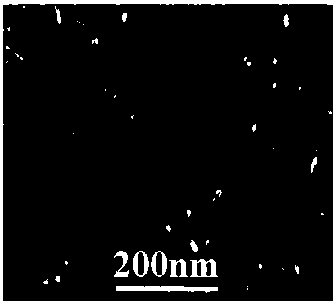

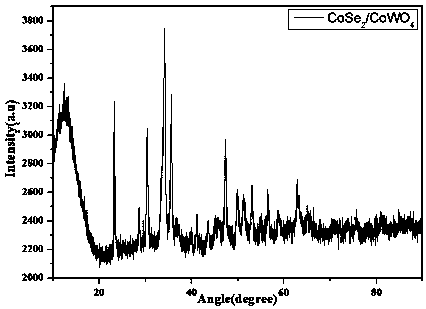

[0027] using hydrothermal method to synthesize cobalt tungstate, the specific steps are as follows. 1 mmol of cobalt chloride hexahydrate was dissolved in 20 mL of water to form a solution, which was designated as A; 1 mmol of sodium tungstate dihydrate was dissolved in 20 mL of water to form a transparent solution, which was designated as B. Add B to A to form a purple suspension, stir for 15 minutes to mix evenly, then transfer the purple suspension to a washed and dried autoclave polytetrafluoroethylene liner (V = 50 mL), and then add Continue to stir 0.5 mL of ammonia water for 15 min, then take out the magnet, screw the reactor tightly and seal it, and put it into an electric heating constant temperature blast drying oven at 180°C for 12 h. After the reaction was finished, it was naturally cooled to room temperature, and the product was taken out. Wash several times with high-p...

Embodiment 2

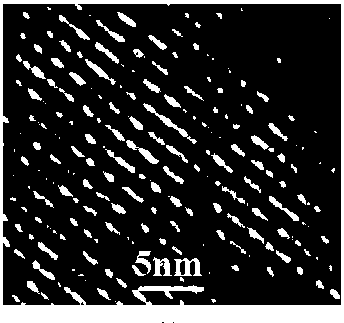

[0029] In this embodiment, cobalt tungstate is used as cobalt source, selenium powder is used as selenium source, solvent is N,N dimethylformamide, sodium hydroxide is alkali, reducing agent is hydrazine hydrate, cobalt diselenide / cobalt tungstate The synthesis process is as follows:

[0030] Add 40 mL of N,N dimethylformamide to the cleaned and dried polytetrafluoroethylene liner (V = 50 mL) of the autoclave, then weigh 7.5 mmol of sodium hydroxide and stir to dissolve, wait for the hydrogen After the sodium oxide is completely dissolved, add 3.75 mmol selenium powder and continue to stir and dissolve. After the selenium powder is dissolved, add 0.8 milliliters of hydrazine hydrate (mass fraction 85%) and continue to stir and mix evenly. Then add the cobalt tungstate synthesized in Example 1 above and continue to stir for 15 minutes. Take out the magnet. After the reaction kettle is screwed tightly and sealed, it is put into an electric heating constant temperature blast dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com