Preparation method and application of fe/alooh catalyst

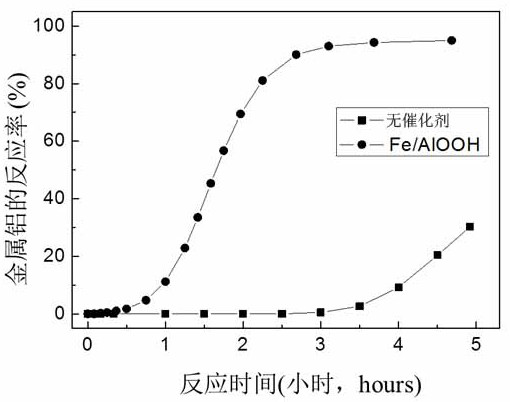

A catalyst, fecl3·6h2o technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low catalytic activity, complex preparation process and corrosiveness and other problems, to achieve the effect of increasing the active area, the hydrogen production process is simple, and the environment is pollution-free.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

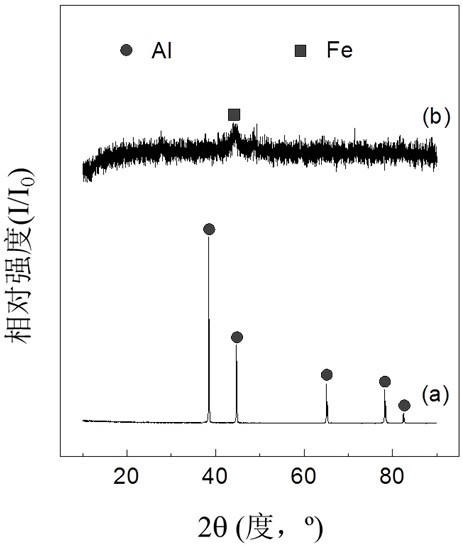

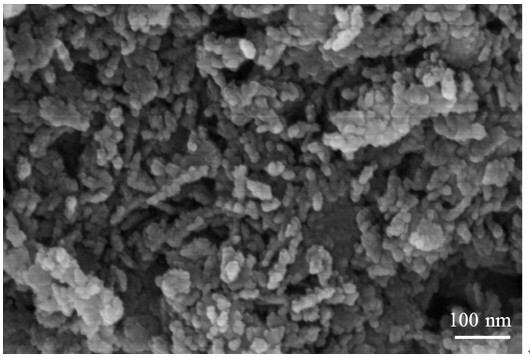

[0027] The preparation method of Fe / AlOOH catalyst comprises the following steps:

[0028] a. At room temperature (25°C), ultrasonic power of 150W, and ultrasonic frequency of 40kHz, add AlOOH powder into a beaker filled with deionized water and place it in an ultrasonic water bath for ultrasonic mixing for 1 hour, then add FeCl 3 ·6H 2 O, continue ultrasonic mixing for 0.5 h to obtain suspension A, the mass ratio of AlOOH powder to water is 1:250, the mass ratio of AlOOH powder to FeCl 3 ·6H 2 The molar ratio of O is 1:1;

[0029] b. Add suspension A in step a to sodium borohydride within 30s, mix (manual stirring is enough), react until black precipitate is formed, no bubbles are generated, and Fe / AlOOH suspension, sodium borohydride and FeCl are obtained 3 ·6H 2 The molar ratio of O is 3:1;

[0030] c. Suction filter the Fe / AlOOH suspension in step b, wash it with deionized water for 3 times, then wash it with absolute ethanol once, filter, and dry at 25°C for 10 h to ...

Embodiment 2

[0034] The preparation method of Fe / AlOOH catalyst comprises the following steps:

[0035] a. At room temperature (25°C), with an ultrasonic power of 120W and an ultrasonic frequency of 30kHz, add AlOOH powder into a beaker filled with deionized water and place it in an ultrasonic water bath for ultrasonic mixing for 3 hours, then add FeCl 3 ·6H 2 O, continue ultrasonic mixing for 2 h to obtain suspension A, the mass ratio of AlOOH powder to water is 1:500, and the mass ratio of AlOOH powder to FeCl 3 ·6H 2 The molar ratio of O is 2:1;

[0036] b. Add suspension A in step a to sodium borohydride within 30s, mix (manual stirring is enough), react until black precipitate is formed, no bubbles are generated, and Fe / AlOOH suspension, sodium borohydride and FeCl are obtained 3 ·6H 2 The molar ratio of O is 3:1;

[0037] c. Suction filter the Fe / AlOOH suspension in step b, wash it with deionized water for 3 times, then wash it with absolute ethanol once, filter, and dry at 25°C...

Embodiment 3

[0041] The preparation method of Fe / AlOOH catalyst comprises the following steps:

[0042] a. At room temperature (25°C), ultrasonic power 300W, ultrasonic frequency 50kHz, add AlOOH powder into a beaker filled with deionized water, put it in an ultrasonic water bath and ultrasonically mix for 0.5h, then add FeCl 3 ·6H 2 O, continue ultrasonic mixing for 0.5h to obtain suspension A, the mass ratio of AlOOH powder to water is 1:100, and the mass ratio of AlOOH powder to FeCl 3 ·6H 2 The molar ratio of O is 0.5:1;

[0043] b. Add suspension A in step a to sodium borohydride within 30s, mix (manual stirring is enough), react until black precipitate is formed, no bubbles are generated, and Fe / AlOOH suspension, sodium borohydride and FeCl are obtained 3 ·6H 2 The molar ratio of O is 3:1;

[0044] c. Suction filter the Fe / AlOOH suspension in step b, wash it with deionized water for 3 times, then wash it with absolute ethanol once, filter, and dry at 25°C for 10 h to obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com