Non-turbulent wave infrared electromagnetic wave denitration device

An infrared and electromagnetic wave technology, applied in the field of non-turbulent infrared electromagnetic wave denitrification devices, can solve the problems of increased operating costs and equipment investment, large power consumption, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

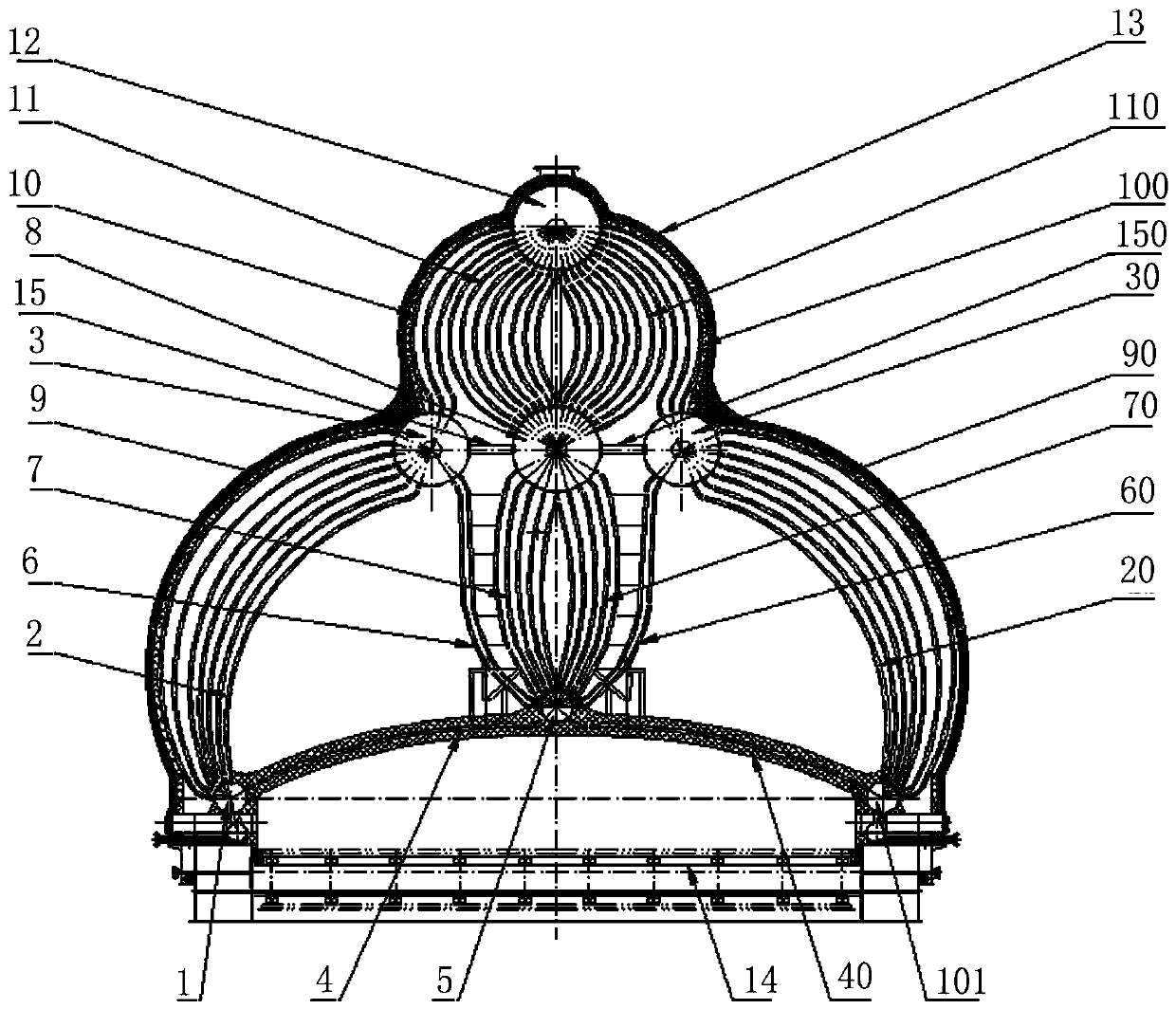

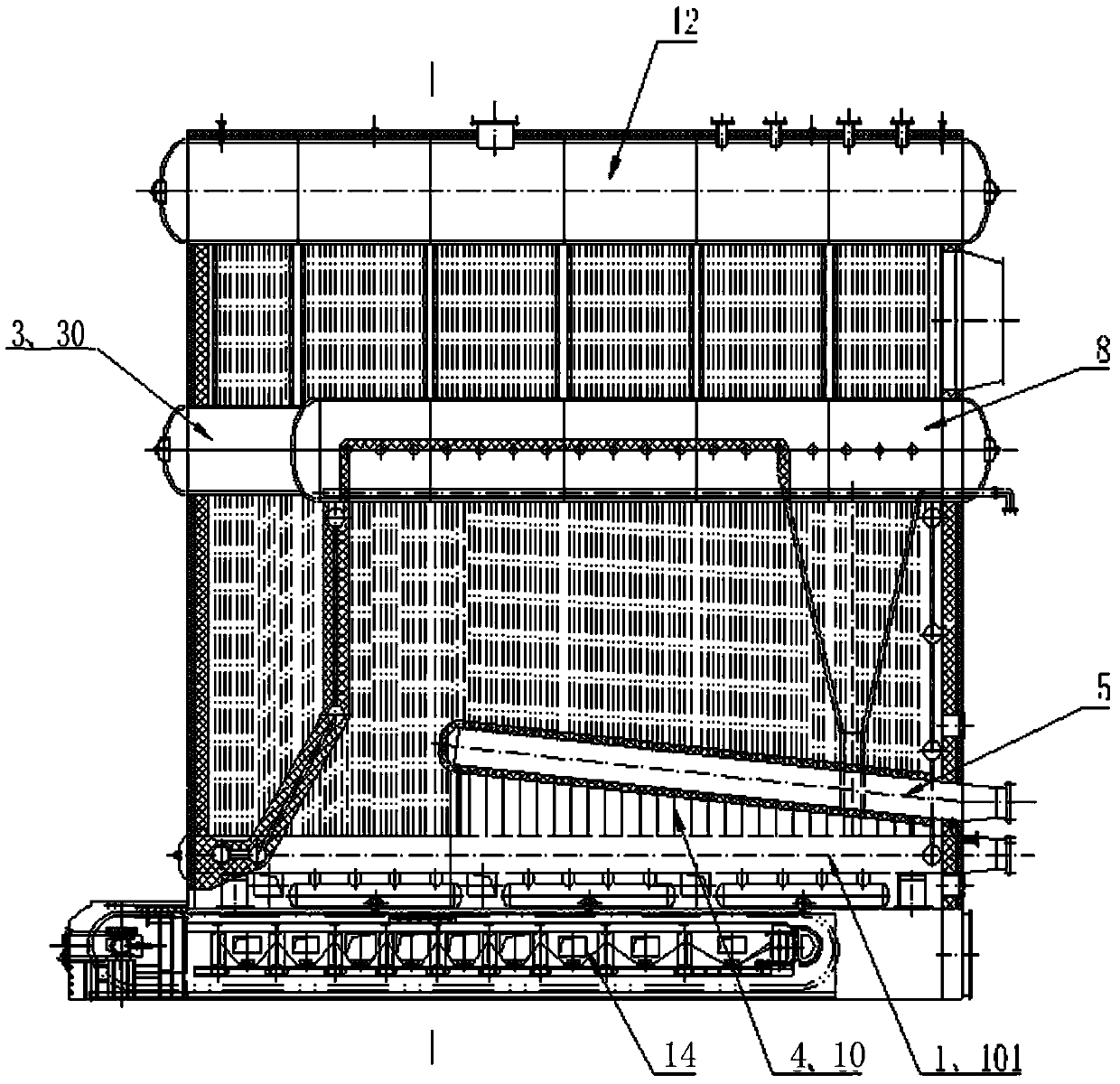

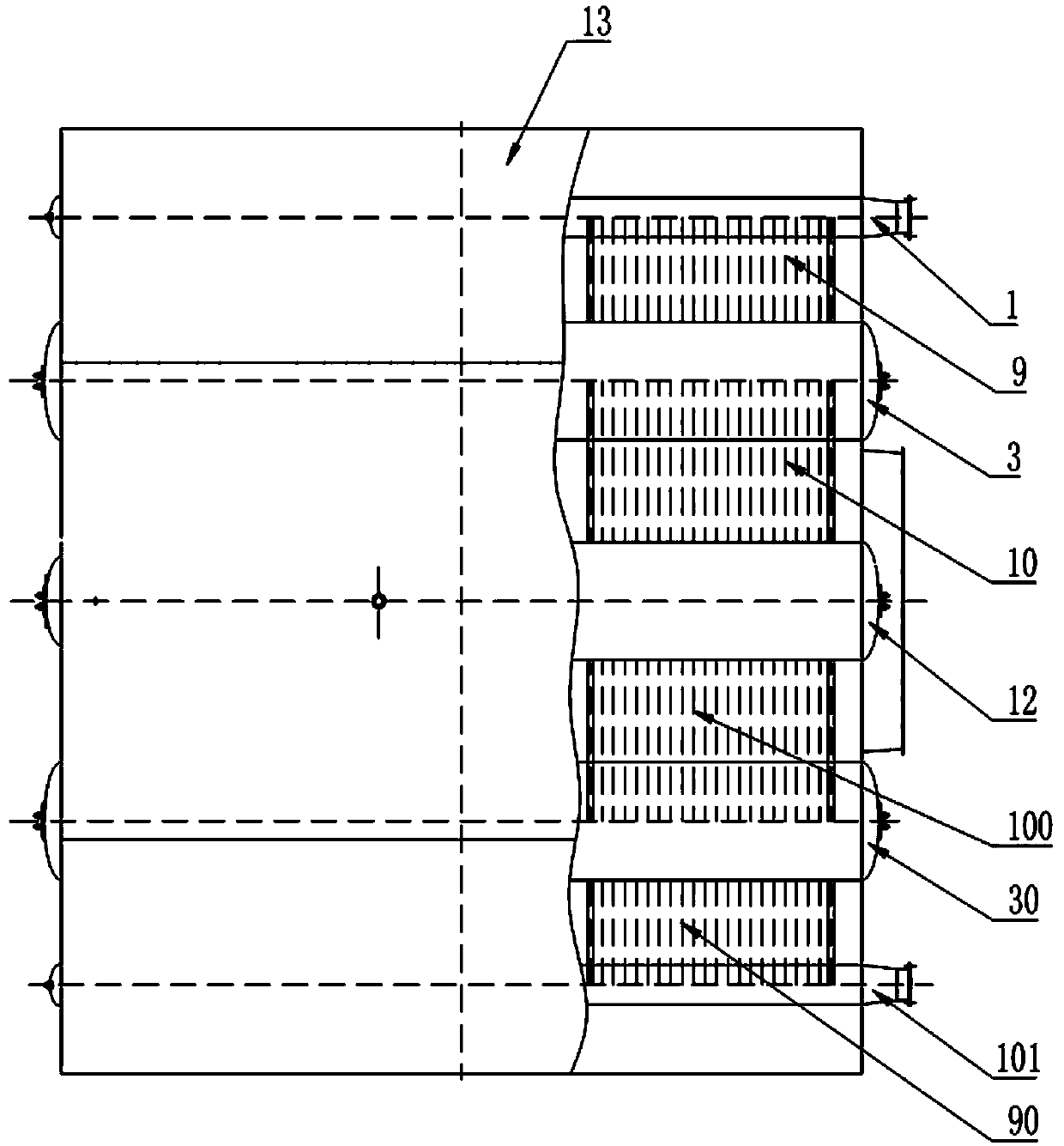

[0025] The invention is a non-turbulent wave infrared electromagnetic wave denitrification device, such as figure 1 As shown, the present invention is composed of three sets of headers in the lower part and four sets of boiler drums in the upper part. The lower header A1, the lower header B101, the left drum 3, and the right drum 30 are connected by a large-arc convection tube to form a beam and focus structure. I-process radiant tube A2, I-process radiant tube B20, II-process outer wall tube A9, II-process outer wall tube B90, and a protective surface 13 built outside the boiler body to form a boiler lower beam and focused non-turbulent infrared electromagnetic wave denitrification device.

[0026] Specifically, the present invention includes the lowermost "thermal oxidation" radiation source structure, the middle I process non-turbulent infrared radiation structure, the central radiation non-turbulent infrared electromagnetic wave denitrification, the II flow arc overlapping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com