Ethylene vinyl alcohol copolymer pellets, resin composition, and multilayer structure

A technology of resin composition and vinyl alcohol, which is applied in the field of resin composition and multilayer structure, can solve the problems of lowering the quality of molded products, thermal deterioration, etc., and achieve the effect of difficult quality and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0138] Hereinafter, although an Example is given and this invention is demonstrated more concretely, this invention is not limited to a following example unless the summary is exceeded.

[0139] In addition, in the following description, "part", "%", and "ppm" all refer to a weight basis. But "mol%" is directly "mol%".

[0140] In addition, each physical property was measured as follows.

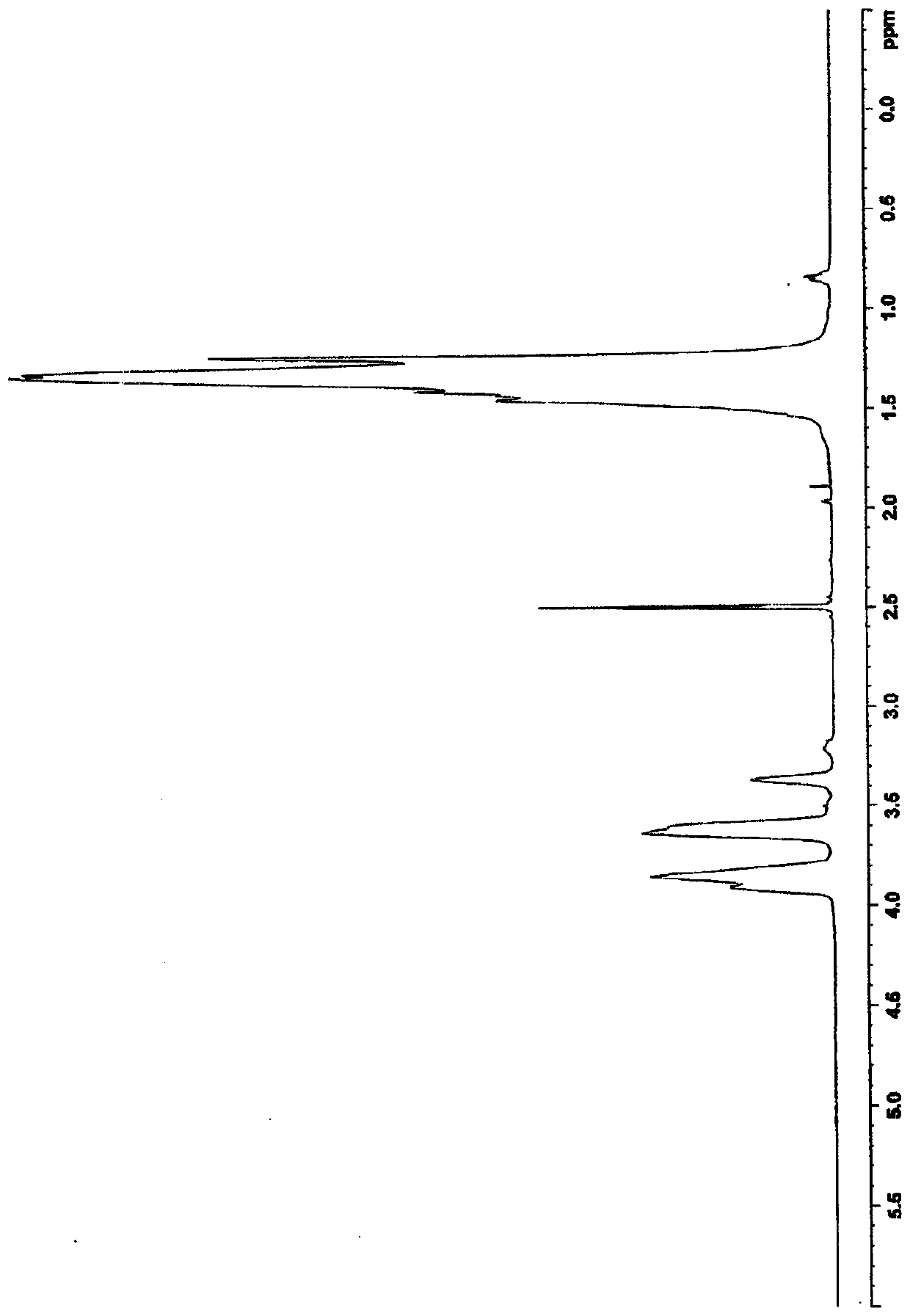

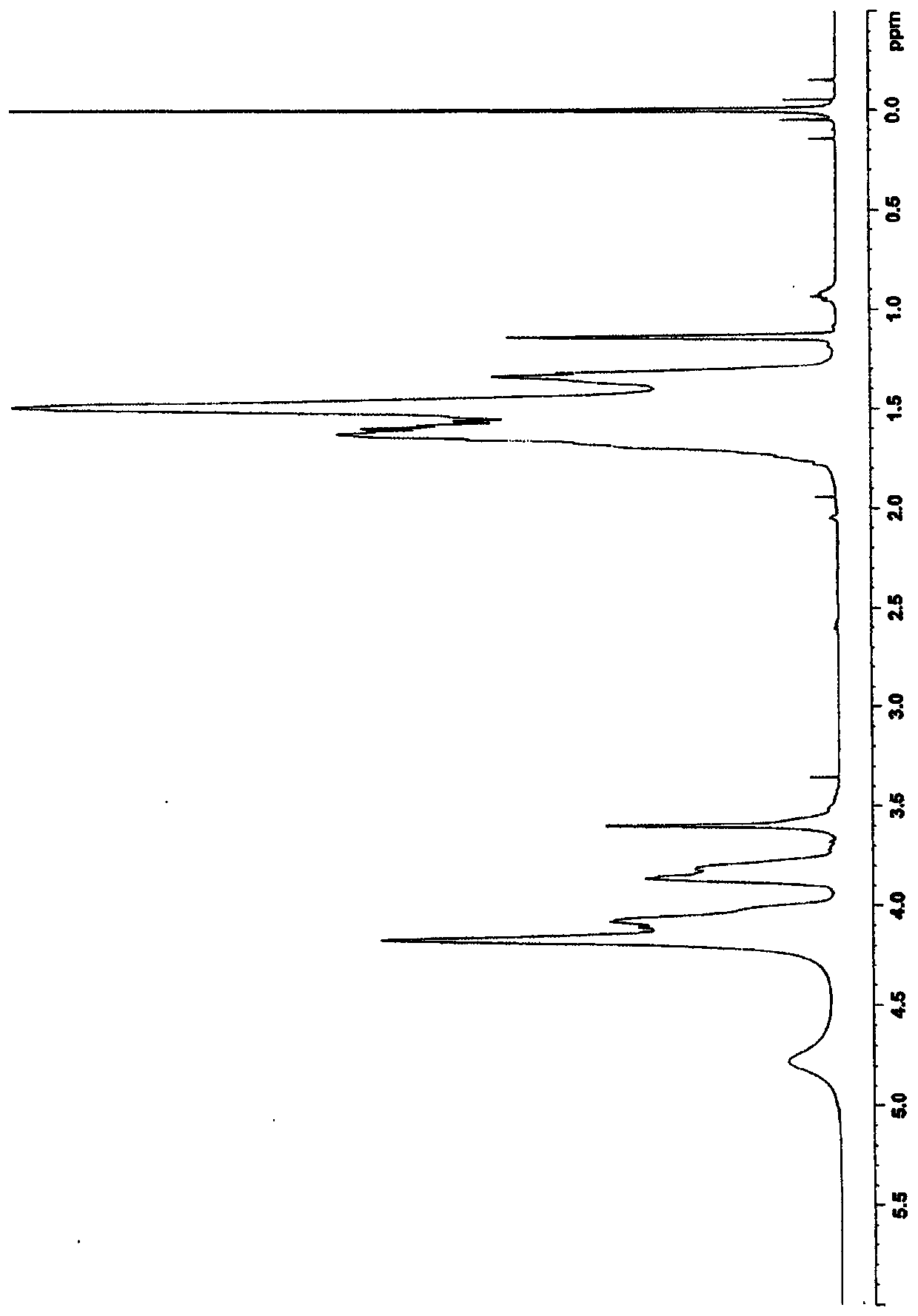

[0141] (1) Quantification of the terminal structure of EVOH: NMR method

[0142]

[0143] Device name: (manufactured by AVANCEIII Bruker)

[0144] Observation frequency: 400MHz

[0145] Solvent: heavy water / ethanol-D6 [heavy water (35) / ethanol-D6 (65), weight ratio], DMSO-D6

[0146] Polymer Concentration: 5%

[0147] Measurement temperature: heavy water / ethanol-D6 70°C, DMSO-D6 50°C

[0148] Cumulative times: 16 times

[0149] Pulse repetition time: 4 seconds

[0150] Sample rotation speed: 20Hz

[0151] Additive: Trifluoroacetic acid

[0152]

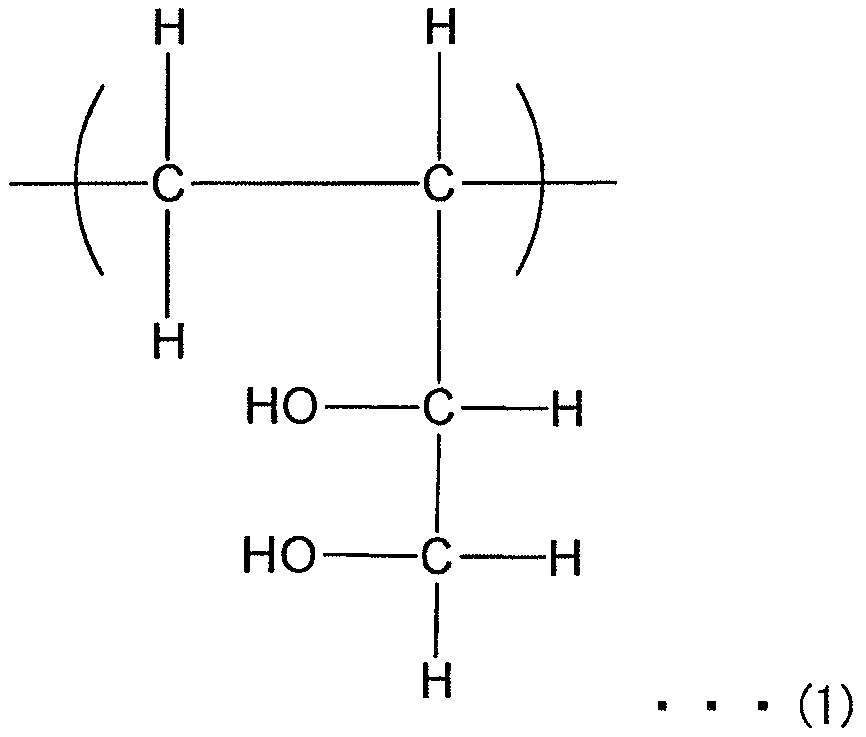

[0153] (1-1) Determination of a...

reference example 1

[0184] A water / methanol mixed solution (water 35 / methanol 65, weight ratio, EVOH resin concentration 40%). Then, the solution of the EVOH intermediate is extruded into a water tank containing cold water in a strand form, cut off with a cutter after making it solidified, and obtains cylindrical EVOH intermediate pellets (100 parts relative to the EVOH intermediate, Contains 100 parts of water).

[0185] Then, put the above-mentioned EVOH intermediate pellets into an aqueous solution containing 350 ppm of acetic acid, 370 ppm of sodium acetate, 15 ppm of calcium dihydrogen phosphate, and 57 ppm of boric acid, and stir at 30 to 35° C. for 1 hour, then replace the aqueous solution. A total of 5 times of stirring treatment (chemical treatment process of the first stage) were carried out. In the aqueous solution used in the first-stage chemical treatment step, the weight ratio of the carboxylic acid concentration to the metal ion concentration of the metal carboxylate salt (carbox...

Embodiment 1

[0189] The amount of acetic acid in the aqueous solution in the second-stage chemical treatment process of Reference Example 1 was changed from 700 ppm to 1400 ppm, and the concentration of carboxylic acid in the aqueous solution used in the second-stage chemical treatment process was compared with that of the metal carboxylate. EVOH pellets were obtained in the same manner as in Reference Example 1 except that the weight ratio (carboxylic acid concentration / metal ion concentration) of the metal ion concentration was 13.5. Various measurement results of the obtained EVOH pellets are shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| drawing temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com