Combined high-capacity wire feeding and braking unit structure based on crimping type IEGT

A brake unit and crimping technology, which is applied in the direction of electrical components, output power conversion devices, electrical equipment structural parts, etc., can solve the problems of low integration, small maintenance space, large size, etc., and achieve a reasonable unit layout Compact, easy to maintain, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

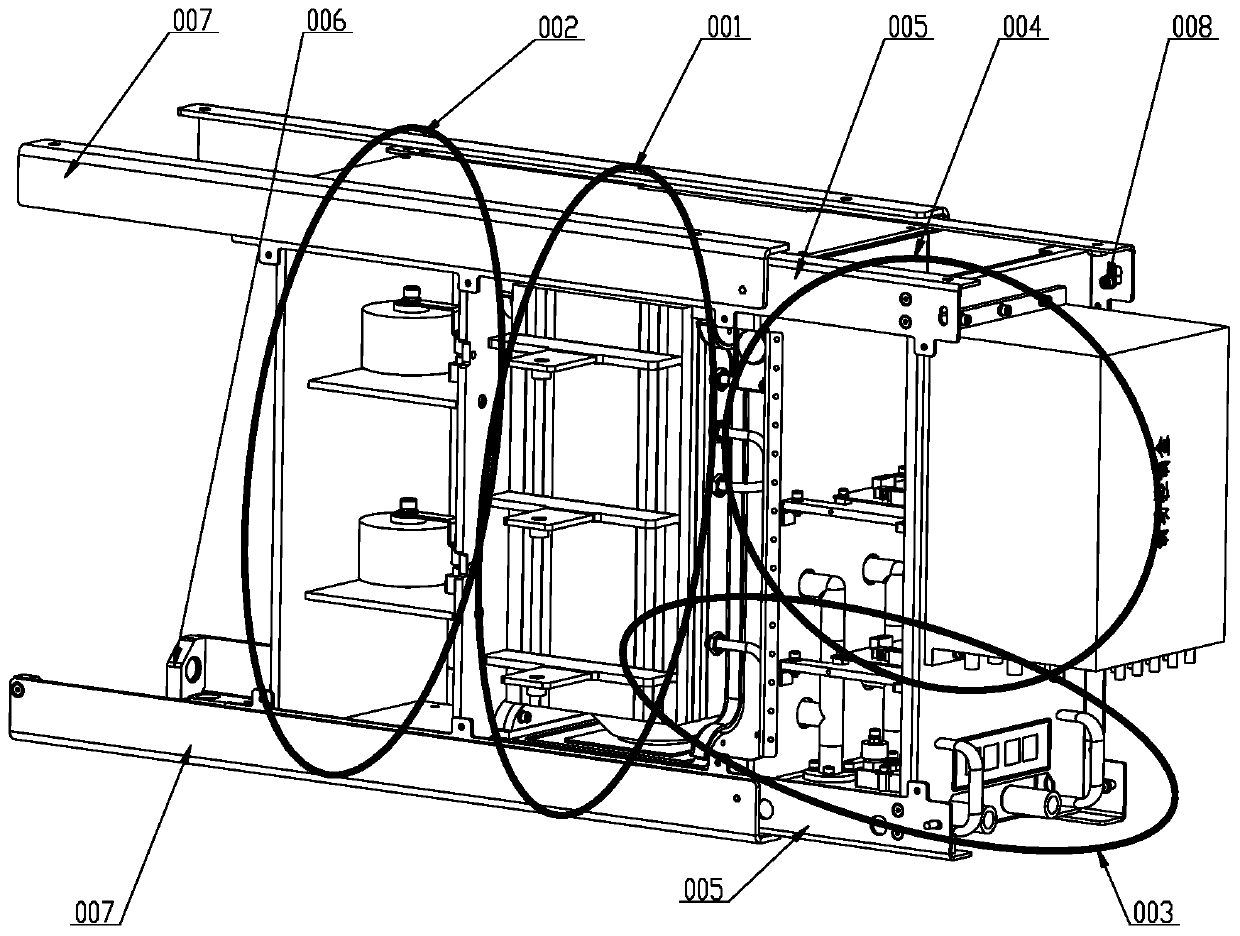

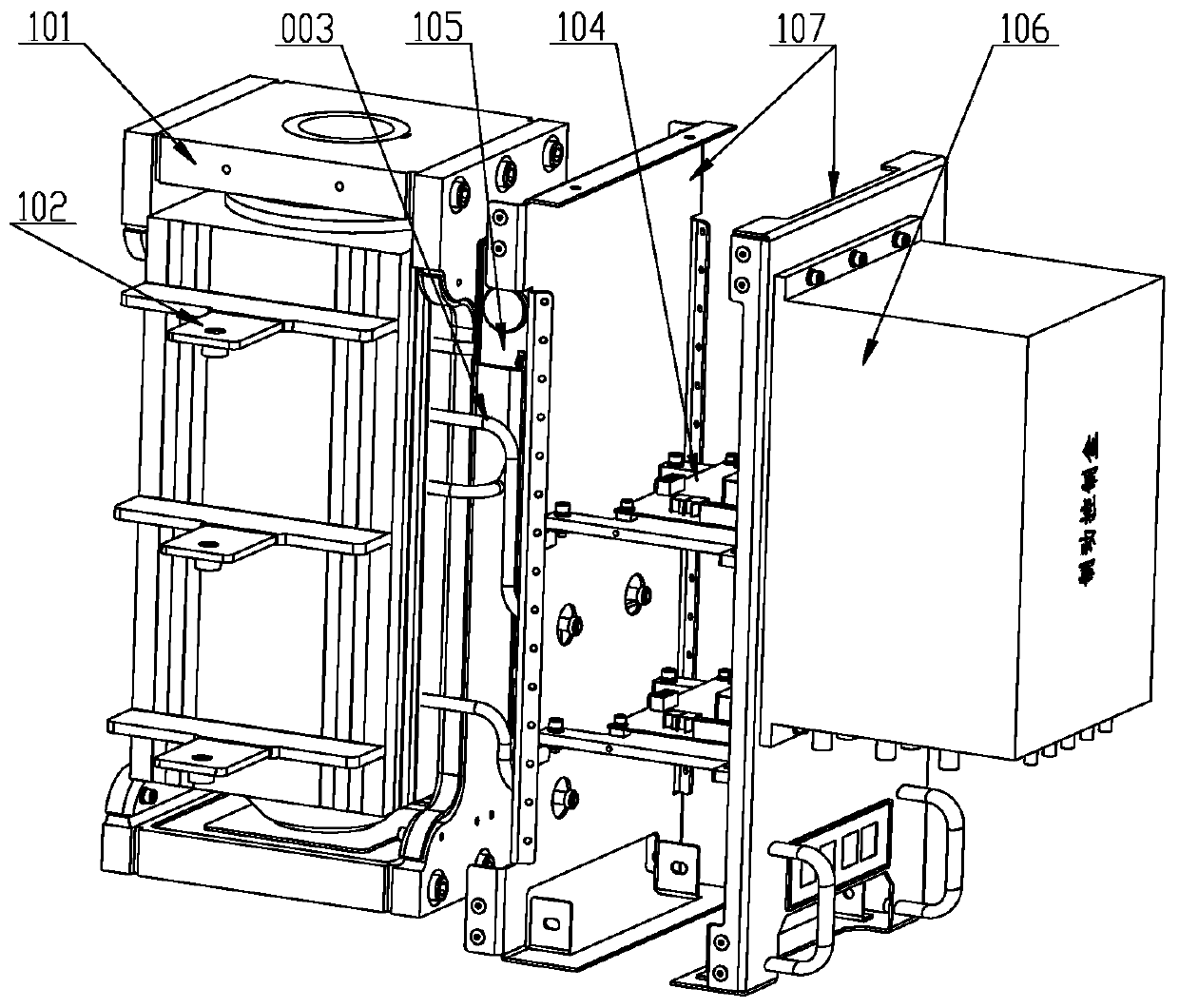

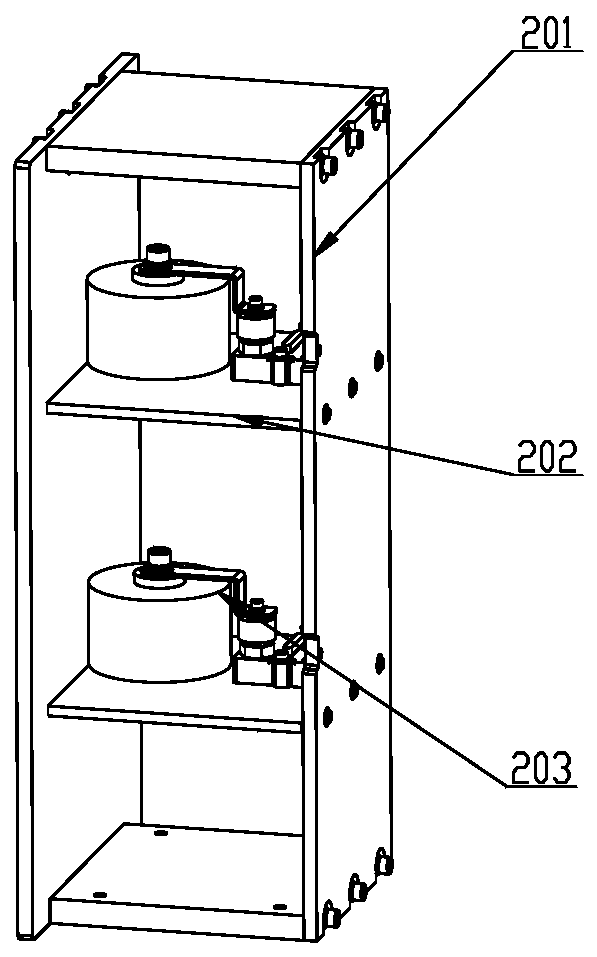

[0029] See figure 1 , Figure 5 , based on the combined large-capacity incoming line braking unit structure of the press-fit IEGT, the incoming line unit and the braking unit are combined into a unit structure, including the control part 004, the valve string part 001, the RC absorption circuit part 002, and the water cooling tube Road 003; the control part 004, the valve string part 001, and the RC absorption circuit part 002 are arranged in sequence from front to back, and the water cooling pipeline 003 is the heat dissipation of the control part 004, the valve string part 001, and the RC absorption circuit part 002; the above four parts It is fixed on the unit frame 005, and the automatic positioning structure 006 is fixed on the rear and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com