Preparation method of conductive polymer carbon material composite thin film

A conductive polymer and composite film technology, which is applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of the limitation of the size of the synthesized product and the size of the electrode, and it is difficult to accurately control the content and dispersion of CNTs, and achieve energy storage. The effect of enhanced performance, high polymerization efficiency, and improved overall conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1.1 Raw materials

[0032] Pyrrole (Pyrrole, Py); multi-walled carbon nanotubes (MWCNTs, diameter 10-20nm, length 10-30μm, purity>95%); perchloric acid (HClO 4 ); Chloroform (CHCl 3 ); concentrated sulfuric acid (H 2 SO 4 ).

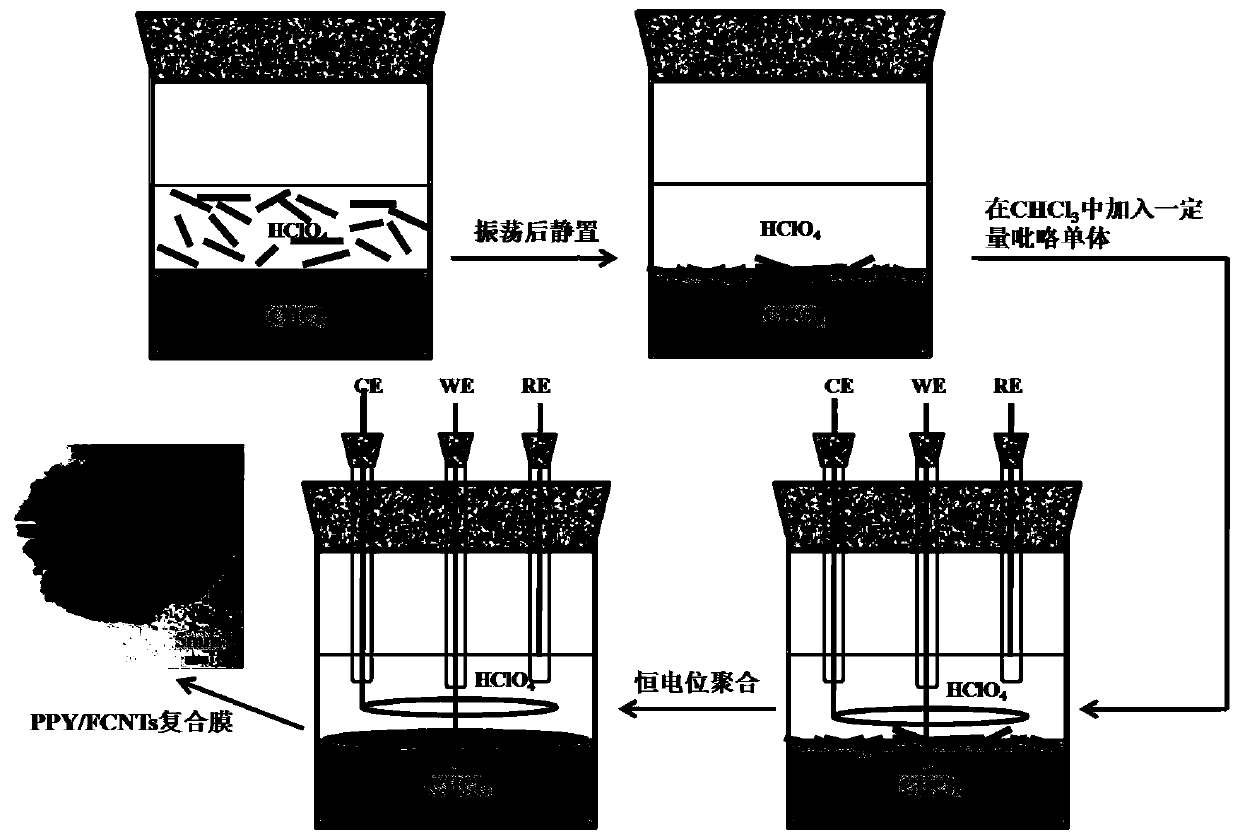

[0033] 1.2 Preparation of hydroxylated MWCNTs and assembly of carbon nanotubes at the oil / water interface (multi-walled carbon nano-MWCNTs)

[0034] 1.2.1 Preparation of hydroxylated MWCNTs

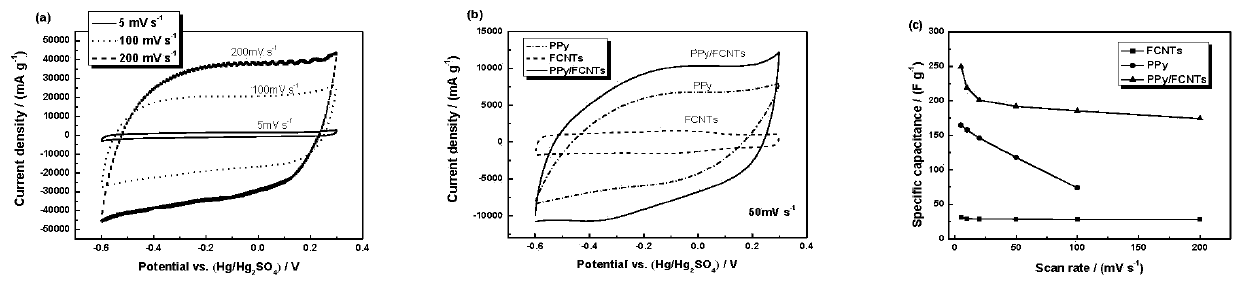

[0035] Take a certain amount of MWCNT and place it in a 250mL round bottom flask, add 100mL of concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:3, shake gently, heat to 140°C, reflux for about 3 hours, suction filter after cooling, and use the filter cake Washing with ionic water until neutral, and vacuum drying at 50 °C for 24 h to obtain hydroxylated MWCNTs, denoted as FCNTs. The acidified FCNTs were ultrasonically dispersed in secondary water to obtain FCNTs colloidal aqueous solution. Take 10mL FCNTs aqueous solution...

Embodiment 2

[0045] The steps are the same as above, except that an appropriate amount of FCNTs aqueous solution is added in step 3) so that the dispersion concentration at the oil-water interface is 0.033 μg mm -2 , set aside.

Embodiment 3

[0047] The steps are the same as above, except that an appropriate amount of FCNTs aqueous solution is added in step 3) so that the dispersion concentration at the oil-water interface is 0.132 μg mm -2 , set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com