Winding structure and winding method of transformer coil

A technology of transformer coils and winding methods, which is applied in the field of transformer manufacturing, can solve problems such as space waste, and achieve the effects of reducing waste, reducing consumption, and reducing no-load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

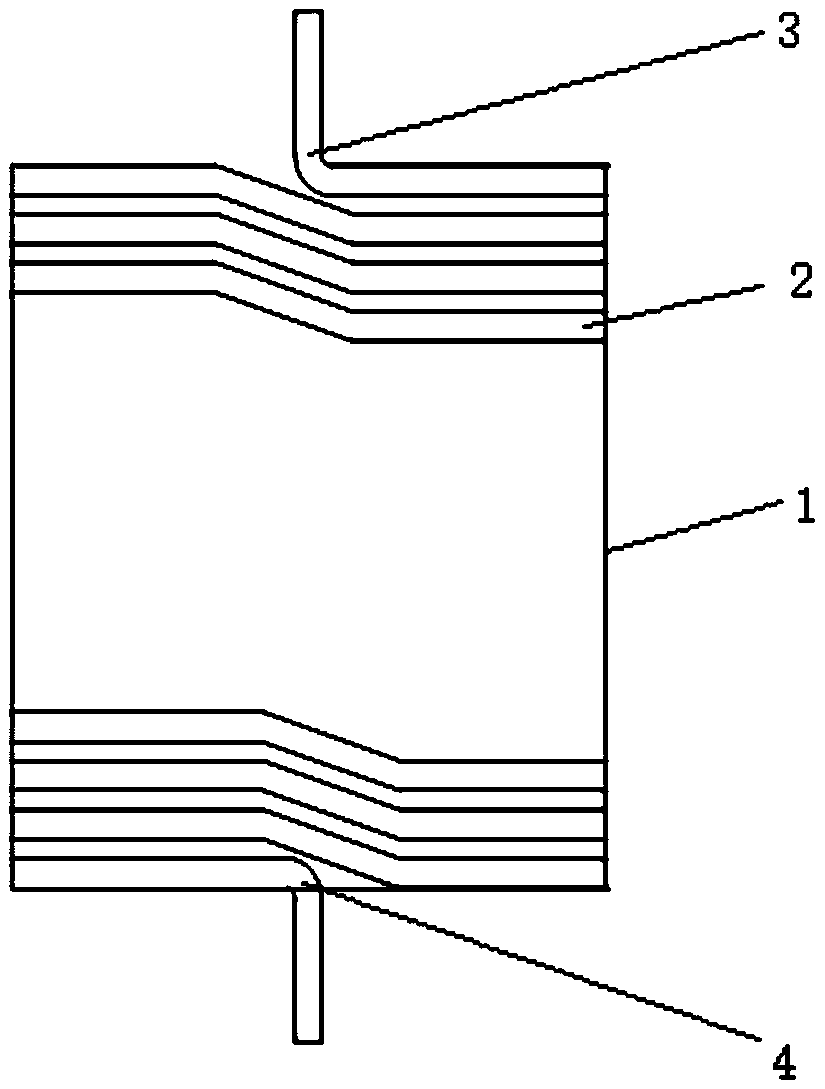

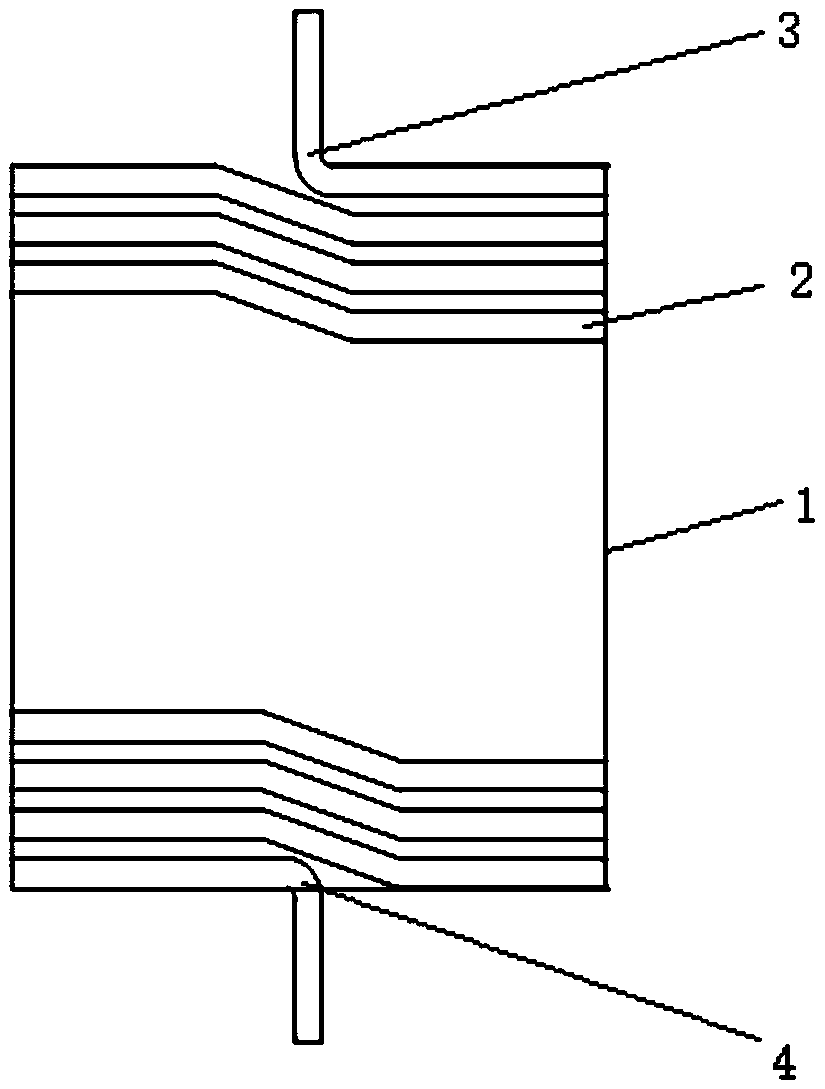

[0027] Please see figure 1 , is a structural schematic diagram of a preferred embodiment of a winding structure of a transformer coil in the present invention, a winding structure of a transformer coil includes a winding mold and a wire body, and the wire body is wound from the winding mold Winding from the end to the end, the wire body is wound clockwise along the direction from the winding end to the end. The wire body of the first turn forms an "S" bend at the winding end, and then the wire body winds a circle horizontally, and then turns Press a diagonal line at the bottom right, the vertical distance between the upper and lower ends of the diagonal line is the sum of the diameter of the wire body and the distance between each turn of the coil, then the wire body continues to wind a circle horizontally, and then press a diagonal line to the bottom right , parallel to the previous oblique line, the vertical distance between the upper end and the lower end of the oblique lin...

Embodiment 2

[0033] A method for winding a transformer coil, comprising the steps of:

[0034] a. Wind the first turn of the coil clockwise from top to bottom from the winding end to the end on the winding mold, and bend the wire body of the first turn at the winding end to form an "S" bend. Bend and wrap the insulating paper, and then wind the wire body horizontally to form the first turn from top to bottom;

[0035] b. At the "S" bend near the starting end of the first turn, draw a slash to the right and down. The vertical distance between the upper end and the lower end of the slash is the sum of the diameter of the wire body and the distance between the coils of each turn , wrap insulating paper at the upper and lower ends of the oblique line, place insulating supports at the upper and lower ends of the oblique line, and then continue winding the wire body horizontally to form the second turn from top to bottom;

[0036] c. Repeat step b to complete the winding of the intermediate coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com