Organic waste gas catalytic combustion integrated device

An organic waste gas, catalytic combustion technology, applied in combustion methods, combustion types, incinerators, etc., can solve the problems of high energy consumption, no effect, complex implementation of treatment devices, etc., to achieve low energy consumption, strong versatility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

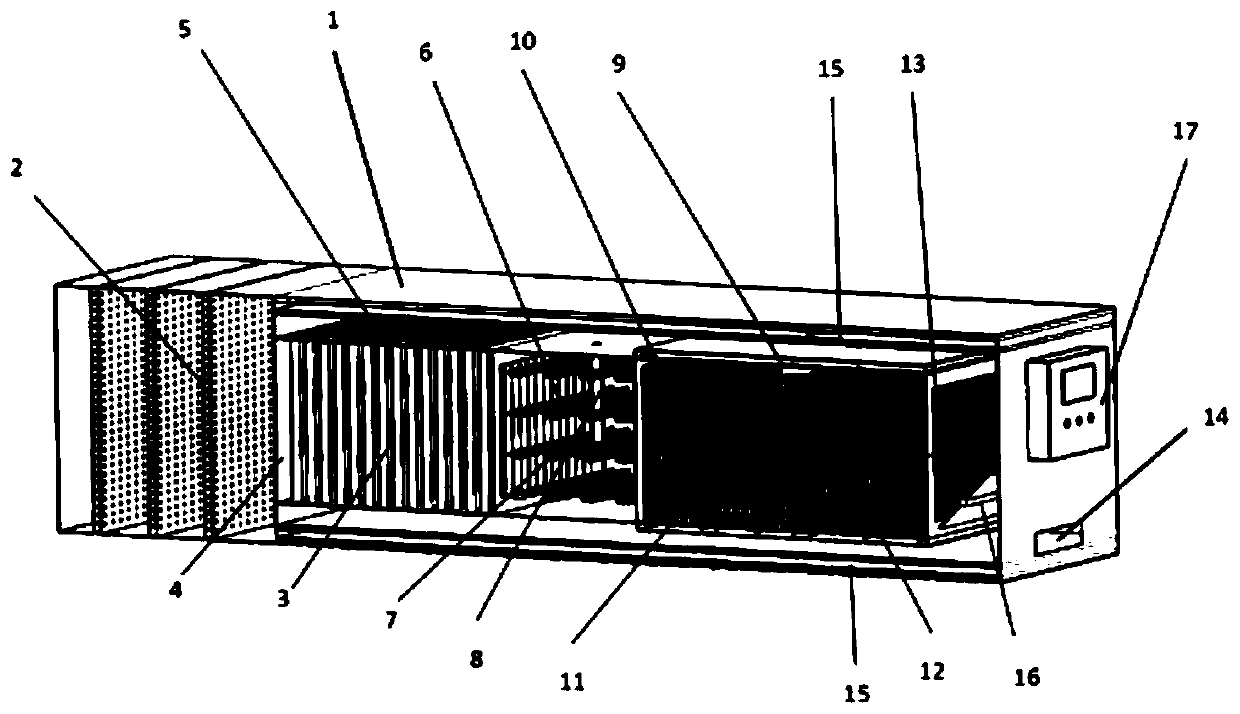

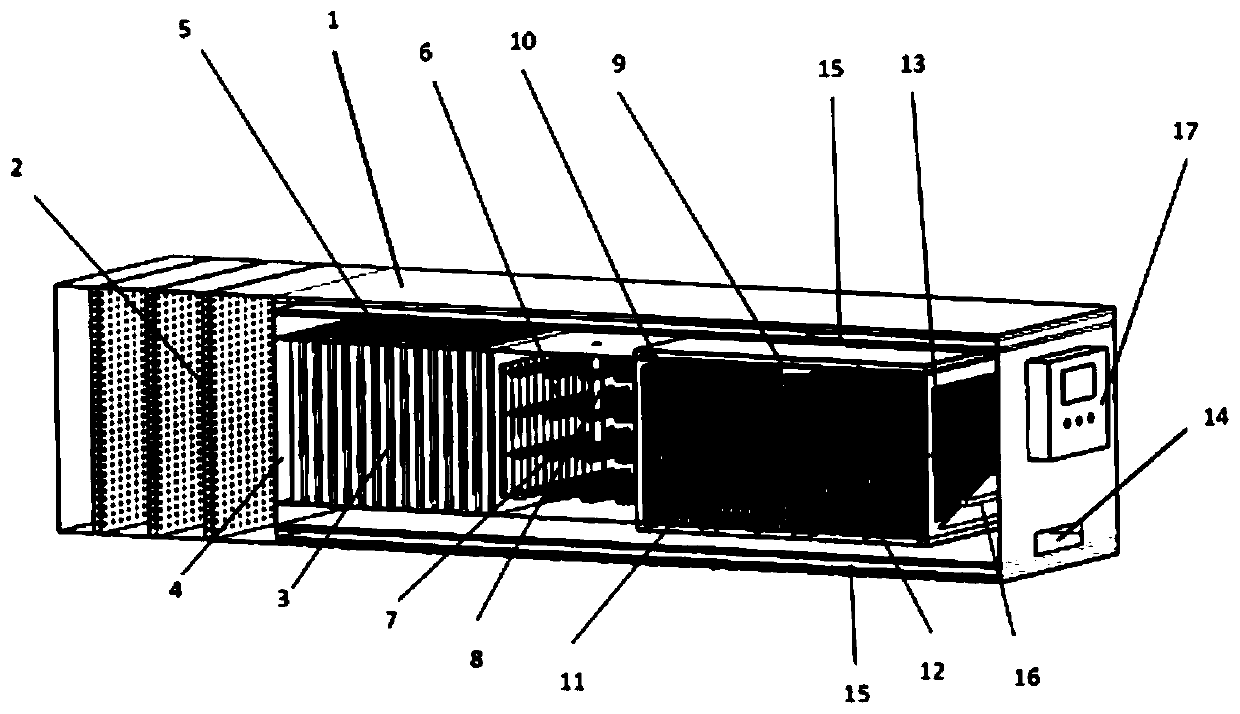

[0027] Such as figure 1 As shown, an organic waste gas catalytic combustion integrated device, the device includes an organic waste gas pretreatment filter device 2, a heat exchanger 3, a heating chamber 6, a catalytic burner 9, and a flow adjustment device 16 sequentially arranged in the main body 1. And the control system 17 provided on the main body 1.

[0028] There are organic waste gas inlets and purified gas outlets 14 on both sides of the main body 1; the organic waste gas inlets are located on the side of the organic waste gas pretreatment system 2, and the purified gas outlets 14 are located on the side of the catalytic combustor 9.

[0029] The filter device 2 is located at the front end of the main body 1 and is used to filter and treat dust and particulate matter in the exhaust gas, realize the pretreatment of the organic exhaust gas, and prevent the cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com