Electric pulse cracking permeability improvement and adsorption and desorption integrated device and method

A technology of adsorption, desorption and electric pulse, which is applied in the direction of safety devices, mining fluids, earthwork drilling and mining, etc., can solve the problem that the protection layer mining is not suitable for single coal seam mining, the direction of hydraulic fracturing is difficult to control, and the deep hole blasting technology is difficult to deliver medicine and other problems, to achieve the effect of wide practicability, simple structure and accurate inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

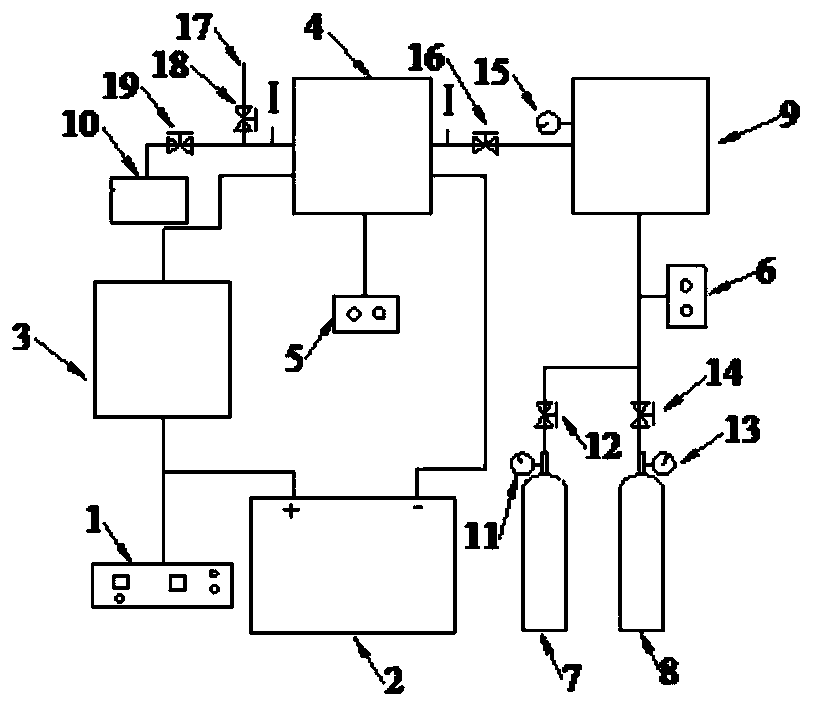

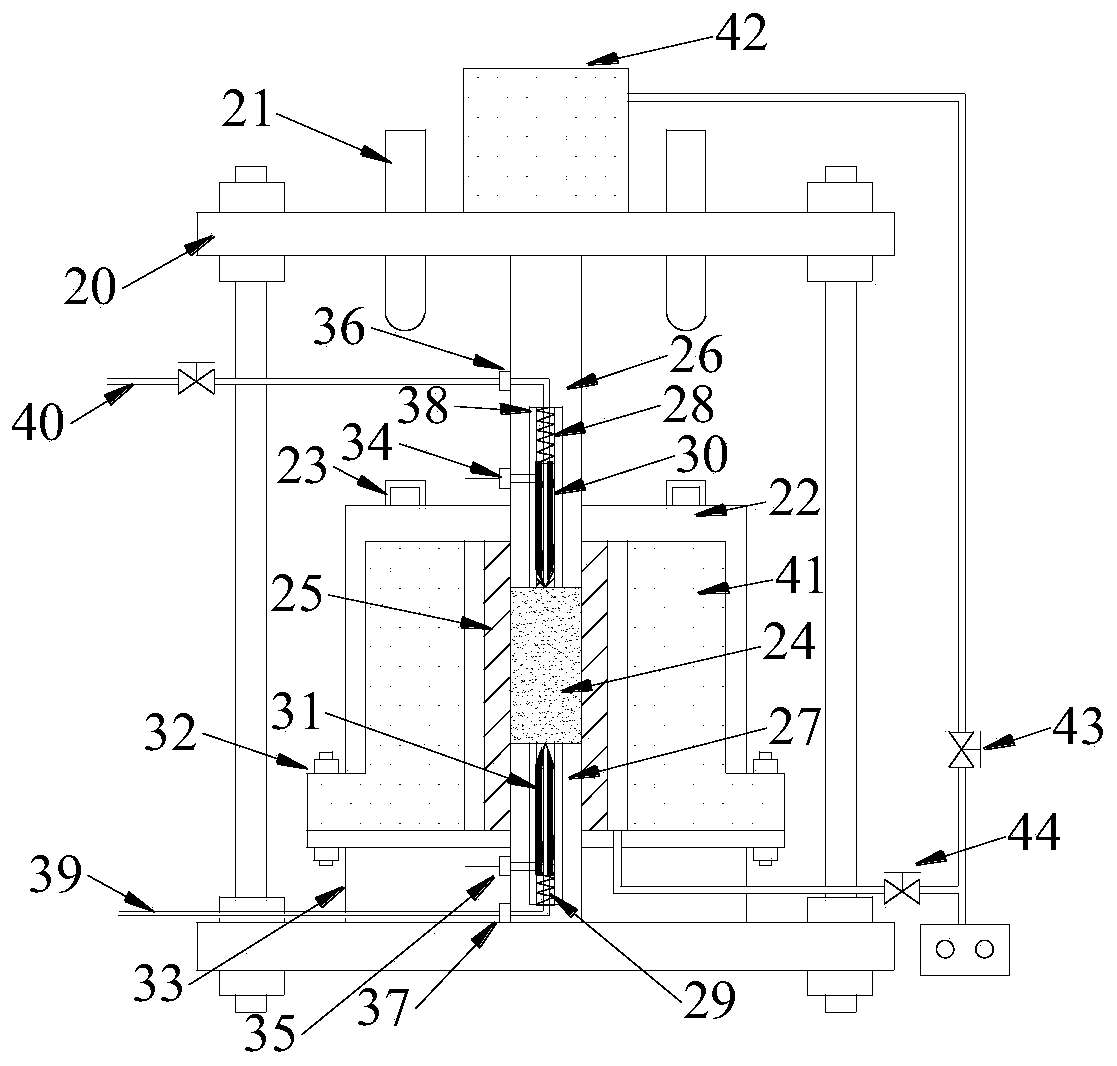

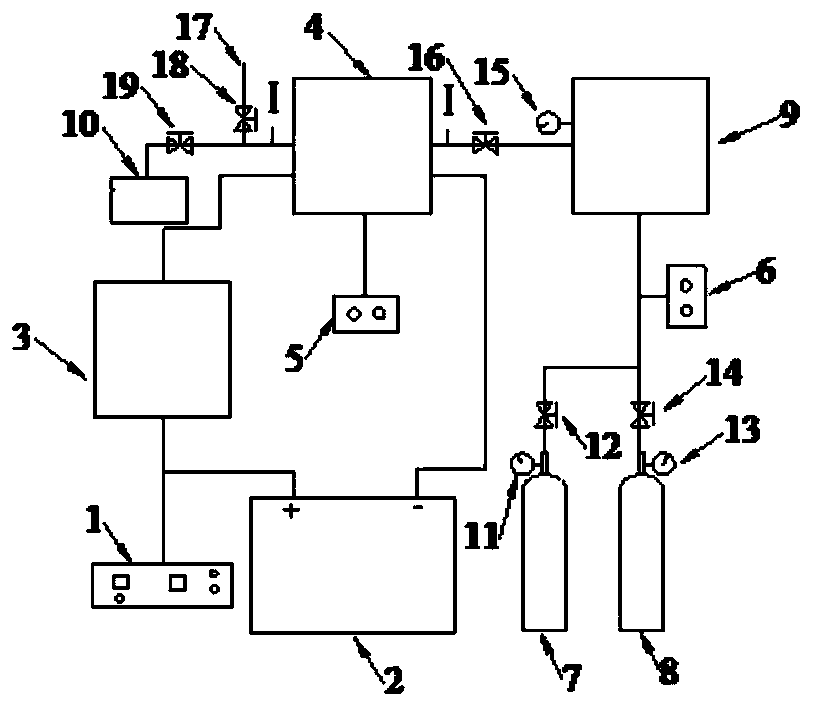

[0027] The electric pulse fracturing antireflection and gas adsorption and desorption integrated device of the present invention mainly includes a high-voltage charging power supply 1, a high-voltage energy storage capacitor 2, a high-voltage discharge switch 3, a coal sample fixing device 4, a hydraulic control system 5, a vacuum pump device 6, Helium cylinder 7, gas cylinder 8, reference tank 9, desorption instrument 10, the gas outlet end of helium cylinder 7 is connected with pressure gauge one 11 and gas outlet control valve 12; the gas outlet end of gas cylinder 8 is connected with pressure gauge two 13 and gas outlet The control valve 2 14; the reference tank 9 is provided with a pressure gauge 3 15; the output end of the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com