Dynamic liquid level prediction method of beam-pumping unit based on particle swarm extreme learning machine

A beam pumping unit and extreme learning machine technology, applied in the field of soft measurement, can solve the problems of high intensity of manual measurement and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

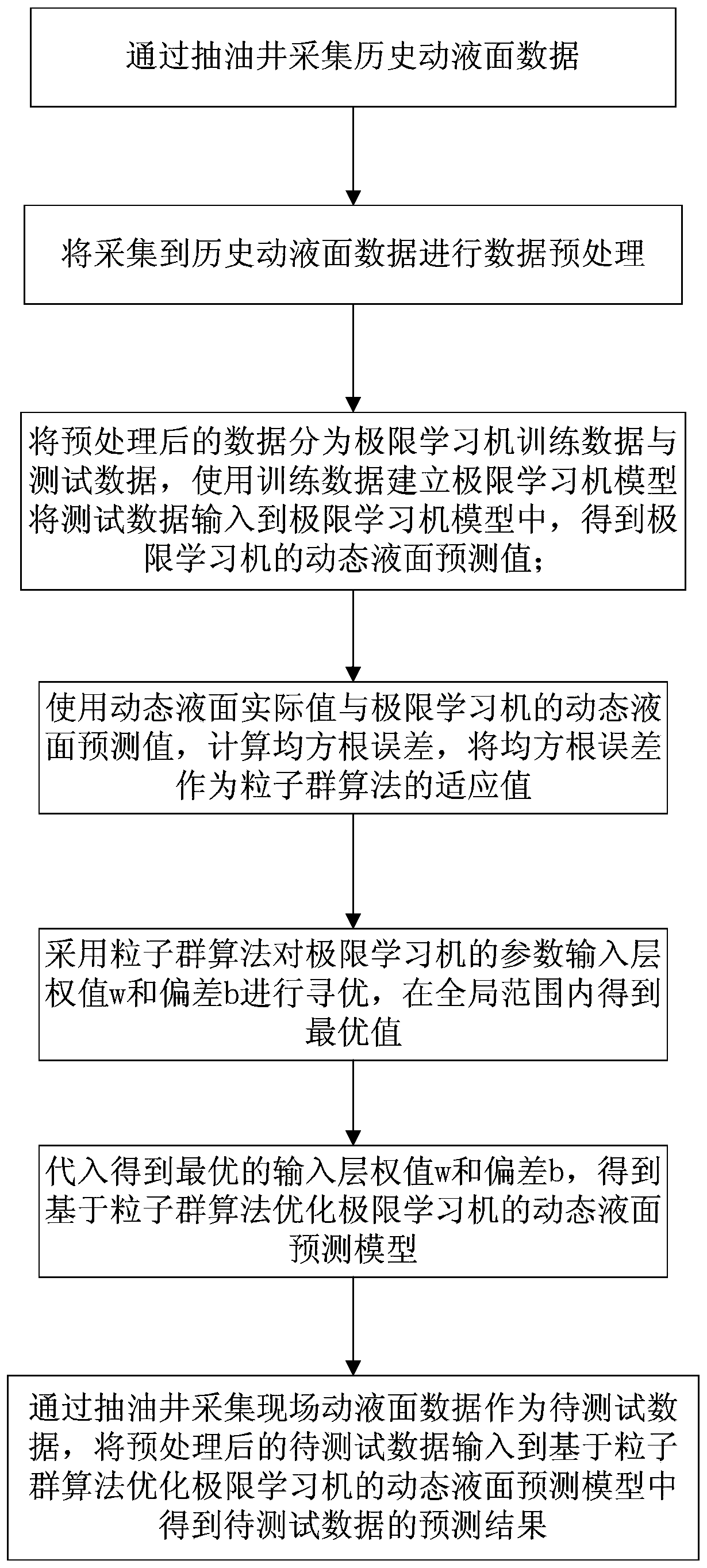

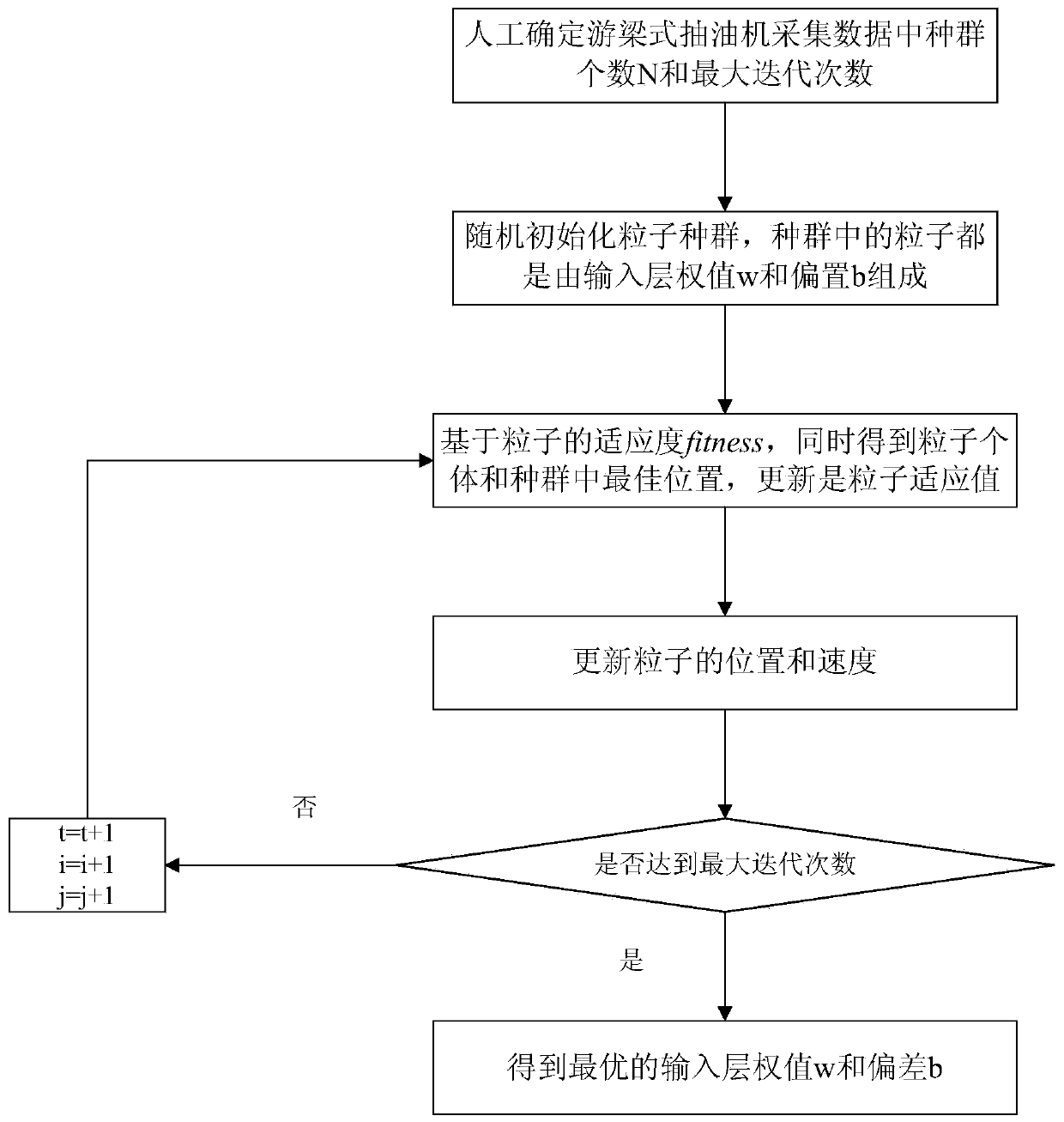

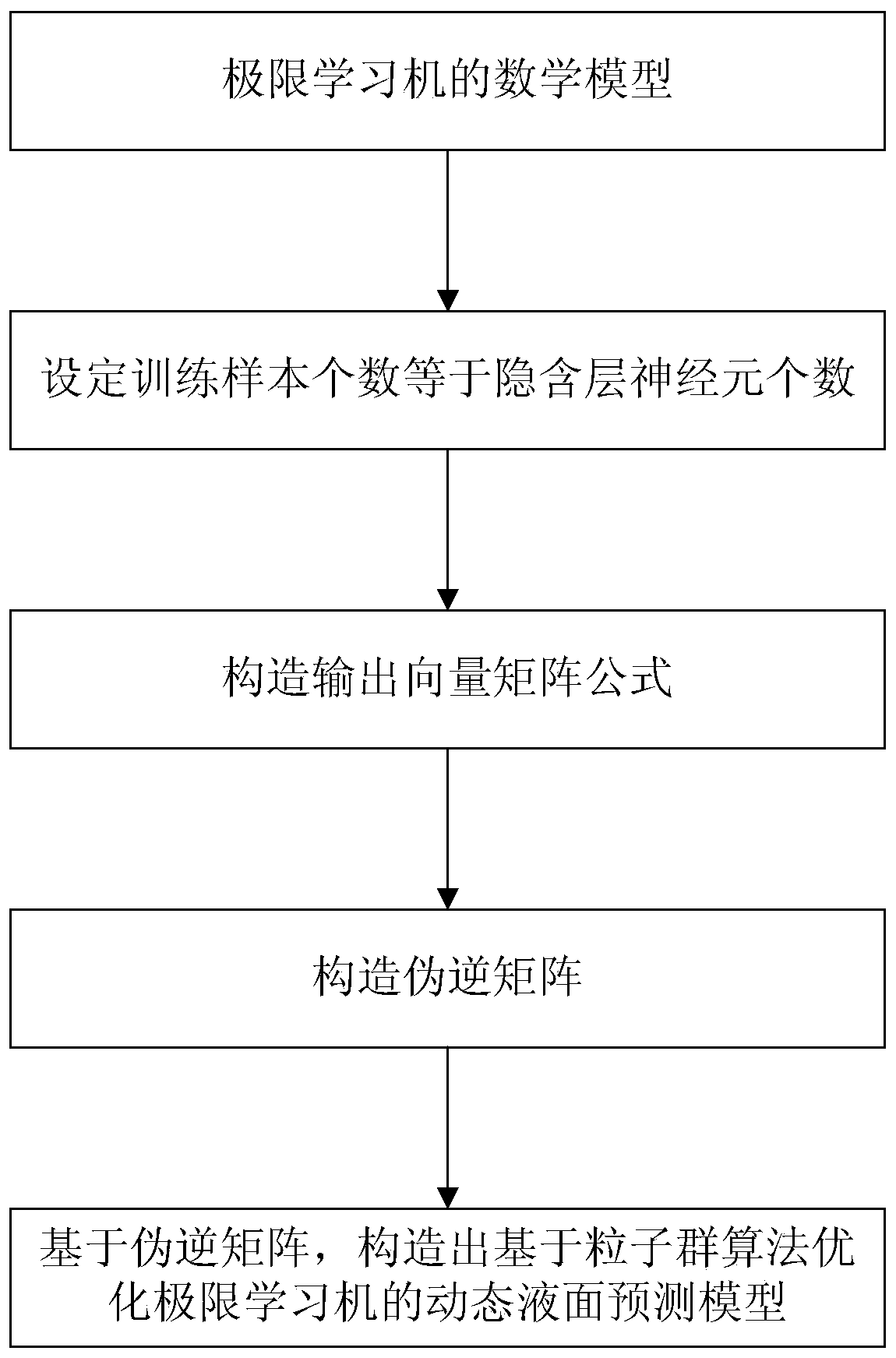

[0070] The invention will be further described below in conjunction with the accompanying drawings and specific implementation examples, as figure 1 As shown, the present invention proposes a method for predicting the dynamic liquid level of a beam pumping unit based on the extreme learning machine of particle swarm, comprising the following steps:

[0071] Step 1: Collect historical dynamic liquid level data through the pumping well, including: suspension point load, suspension point displacement, wellhead oil pressure, wellhead casing pressure, and daily fluid production of the pumping well; suspension point load and suspension point displacement are collected through the indicator diagram It is obtained that the wellhead casing pressure of the beam pumping unit is obtained by installing a pressure measuring instrument at the wellhead. Through the collected indicator diagram data, the average load of the upstroke and downstroke is calculated according to the suspension point ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com