Elastic anti-loosening locking mechanism and its fasteners for wall hangings

An elastic and loose lock technology, which is applied in building construction, covering/lining, construction, etc., can solve problems such as safety hazards, falling from high altitudes, cracking of finishes, etc., and achieve the effect of improving safety factor and preventing loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

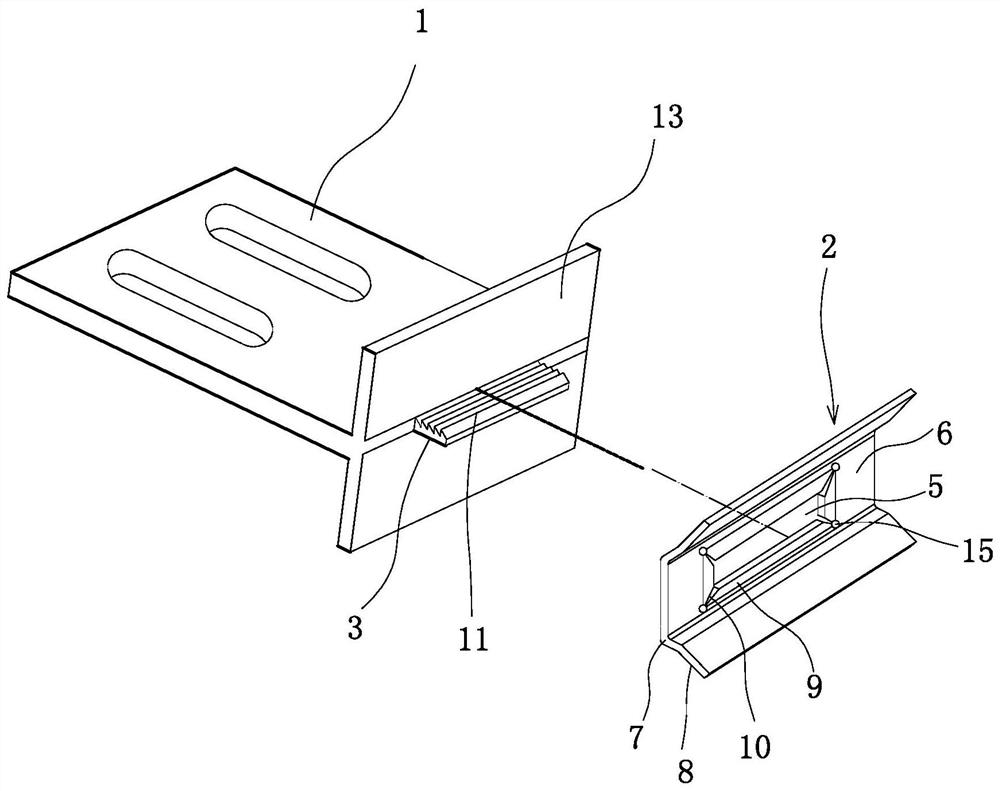

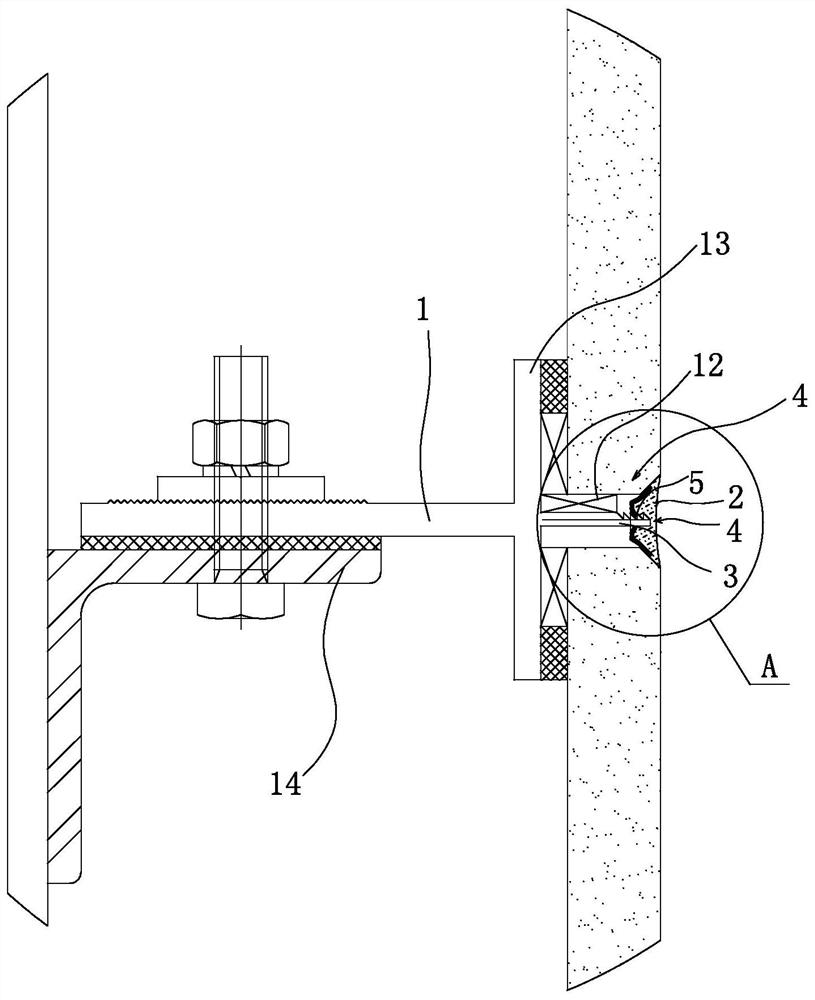

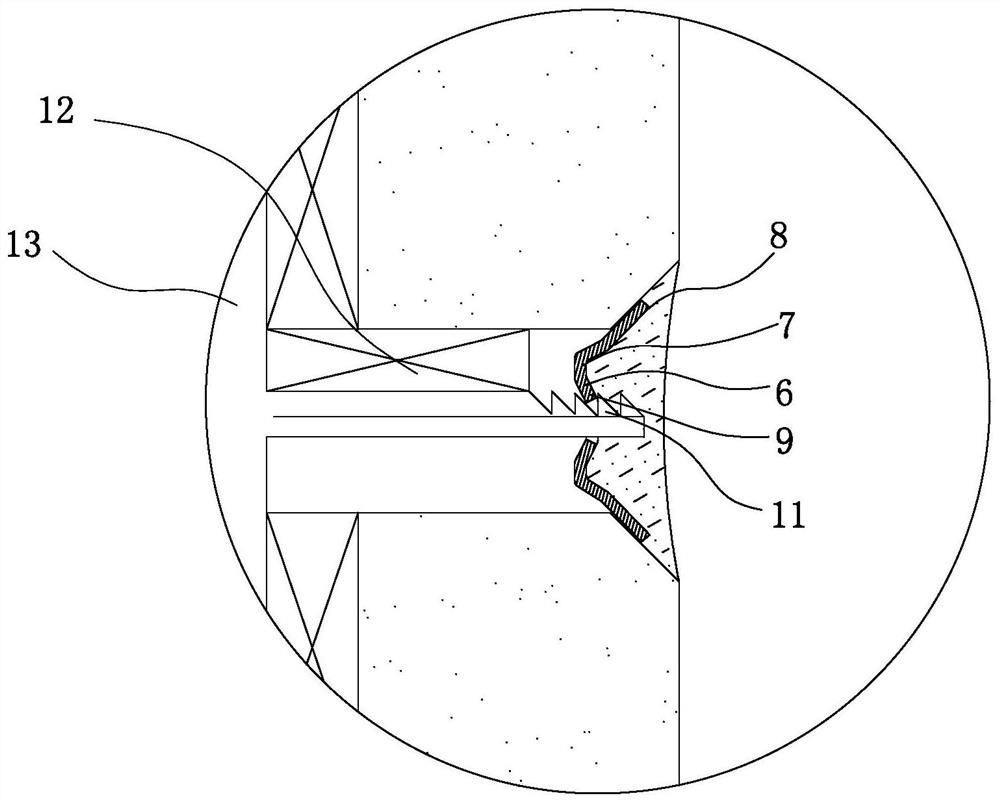

[0033] Such as Figure 1-3 As shown, the elastic anti-loosening locking mechanism of the wall pendant includes a bearing piece 1 and a spring card 2, and a locking block 3 is arranged on one side of the bearing piece 1, and the locking piece 3 and the spring card 2 A connection structure 4 is provided between them, and the spring card 2 is provided with a clamping hole 5, and the spring card 2 is slidably clamped on the locking block 3 through the clamping hole 5, and is fixed by the connection structure 4 Connected to the locking block 3. Such as Figure 4 As shown, those skilled in the art should be able to obtain technical enlightenment, two locking blocks 3 are provided on one side of the carrier sheet 1 . Those skilled in the art should also be able to obtain the technical revelation that multiple locking blocks 3 are provided on one side of the carrier sheet 1 .

[0034] After preliminarily installing the thermal insulation integrated board on the carrier sheet 1, the...

Embodiment 2

[0048] The basic principle of the second embodiment is basically the same as that of the first embodiment, the difference is that, as Figure 4 As shown, a connection seat 16 is provided between the carrier sheet 1 and the mounting seat 14, and at least one upwardly folded slider 17 is provided on the connection seat 16, and a U-shaped chute is provided on the carrier sheet 1. 18 and the U-shaped chute 18 can be interactively connected on the slide block 17, and one side of the slide block 17 is provided with a lateral movement stopper. During the installation process, when the connecting plate 13 deviates from the installation space on the thermal insulation integrated board, the carrier sheet 1 is moved to adapt to the installation holes on the thermal insulation integrated board, so as to achieve the technical effect of easy installation. Simultaneously, the lateral movement stopper limits the moving position of the carrier sheet 1 .

Embodiment 3

[0050] The basic principle of the third embodiment is basically the same as that of the first embodiment, the difference is that, as Figure 6 As shown, the spring card 2 is V-shaped, and the spring card 2 includes an elastic arc portion, and the elastic arc portion is integrally formed with elastic sheets 19 twice, and the sides of the two elastic sheets away from the elastic arc portion are respectively provided with locking The sheet 8, the clamping sheet 8 and the elastic sheet form an angle, and the angle between the clamping sheet 8 and the horizontal plane is greater than 45 degrees. In this embodiment, the angle between the clamping sheet 8 and the horizontal plane is 50 degrees. When the clamping piece 8 is pressed by the veneer, the elastic piece and the elastic arc portion deform to offset the expansion of the veneer. When the veneer shrinks due to cold, the elastic piece and the elastic circular arc part lose the extrusion force and reset, so that the fastening pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com