A deviation correction method for uneven settlement of combined high-voltage transmission poles

A power transmission pole and combined technology, which is applied in the field of rectification of uneven settlement of combined high-voltage power transmission poles, can solve problems such as stress changes, subsidence, and cracking of power transmission poles and wires, and achieve convenient construction, high safety and reliability. The effect of sex, economical cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

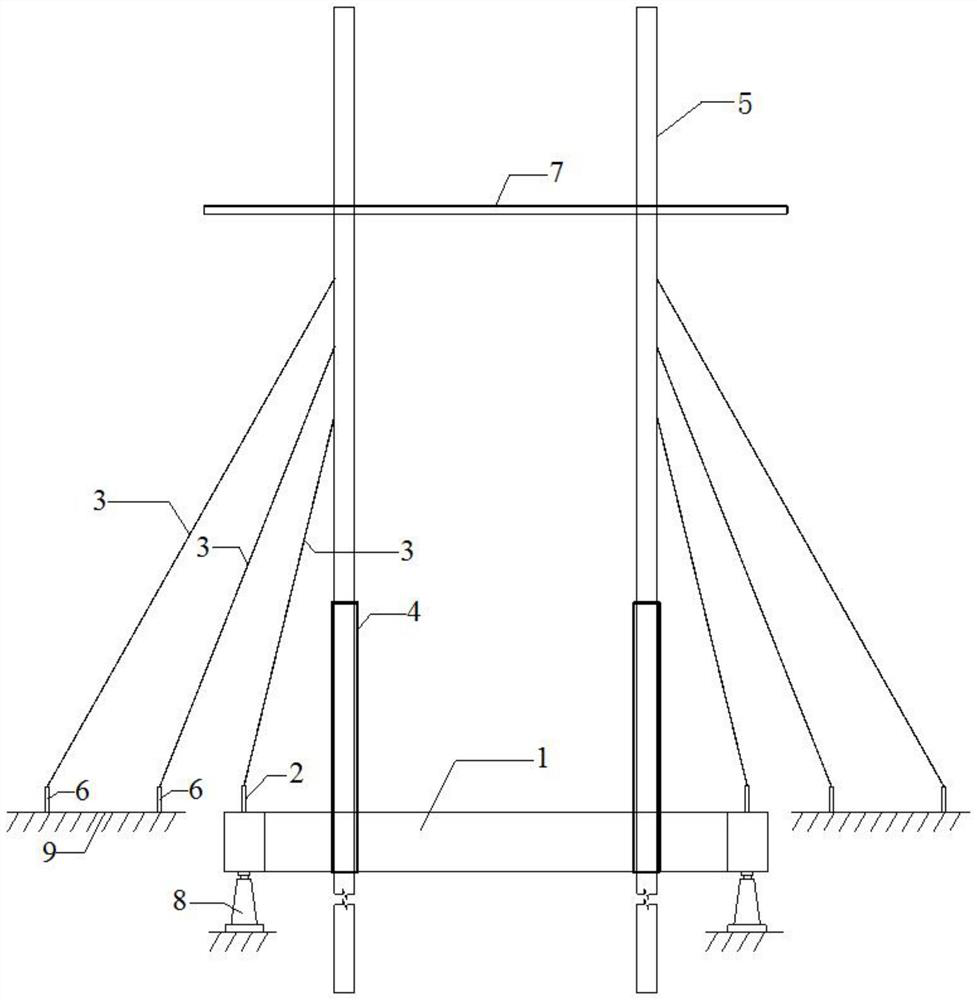

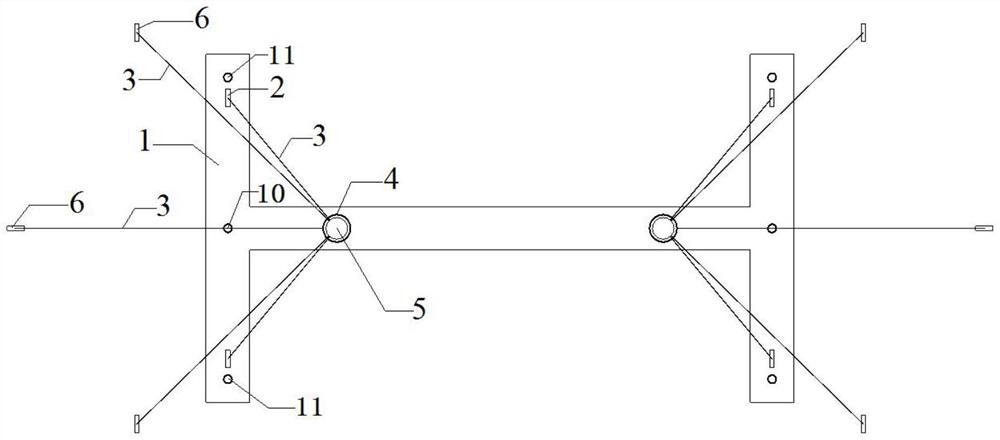

[0026] like figure 1 and figure 2 As shown, a method for rectifying the uneven settlement of a combined high-voltage transmission pole includes the following steps:

[0027] Step 1: In the combined high-voltage transmission poles, the outer sides of the lower parts of the two utility poles 5 are sleeved with hoop steel pipes 4 for reinforcement, wherein the upper parts of the two utility poles 5 are fixedly connected by cross arms 7; in order to better To reinforce the utility pole, the upper end of the hoop steel pipe is close to the middle of the utility pole, and the lower end is close to the ground. As a preferred manner, cement slurry is filled in the gap between the ferrule steel pipe and the utility pole to strengthen the connection between the ferrule steel pipe and the utility pole.

[0028] Step 2: Determine the size of the I-shaped groove at the lower part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com