Automatic woven tape processing device

An automatic processing and webbing technology, applied in the direction of textile, textile, papermaking, weaving auxiliary equipment, etc., can solve the problems of weft yarn fluffing, damage to weft yarn structure, steel wire tail loss, etc., to achieve smooth cutting surface and avoid cutting piece loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

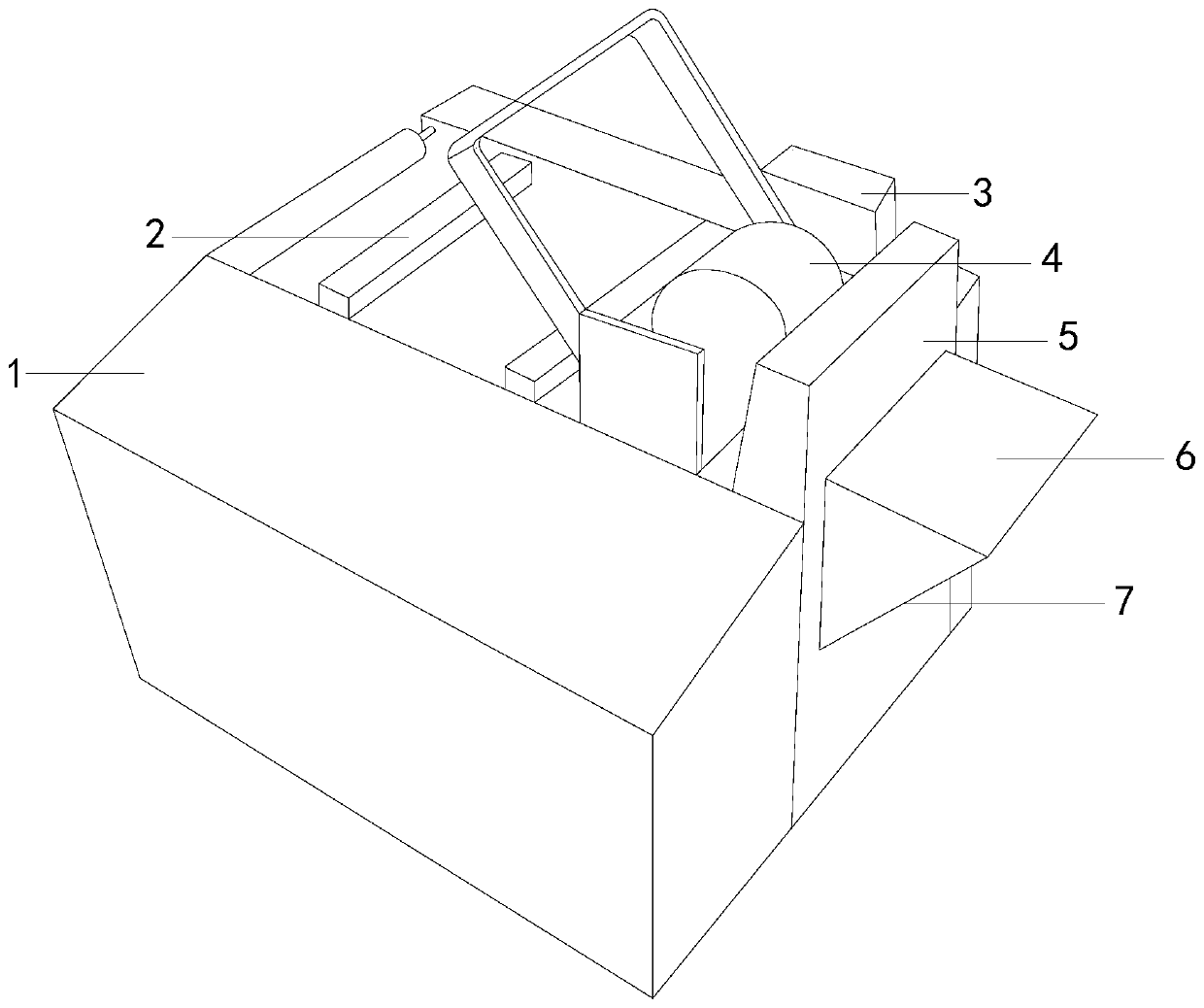

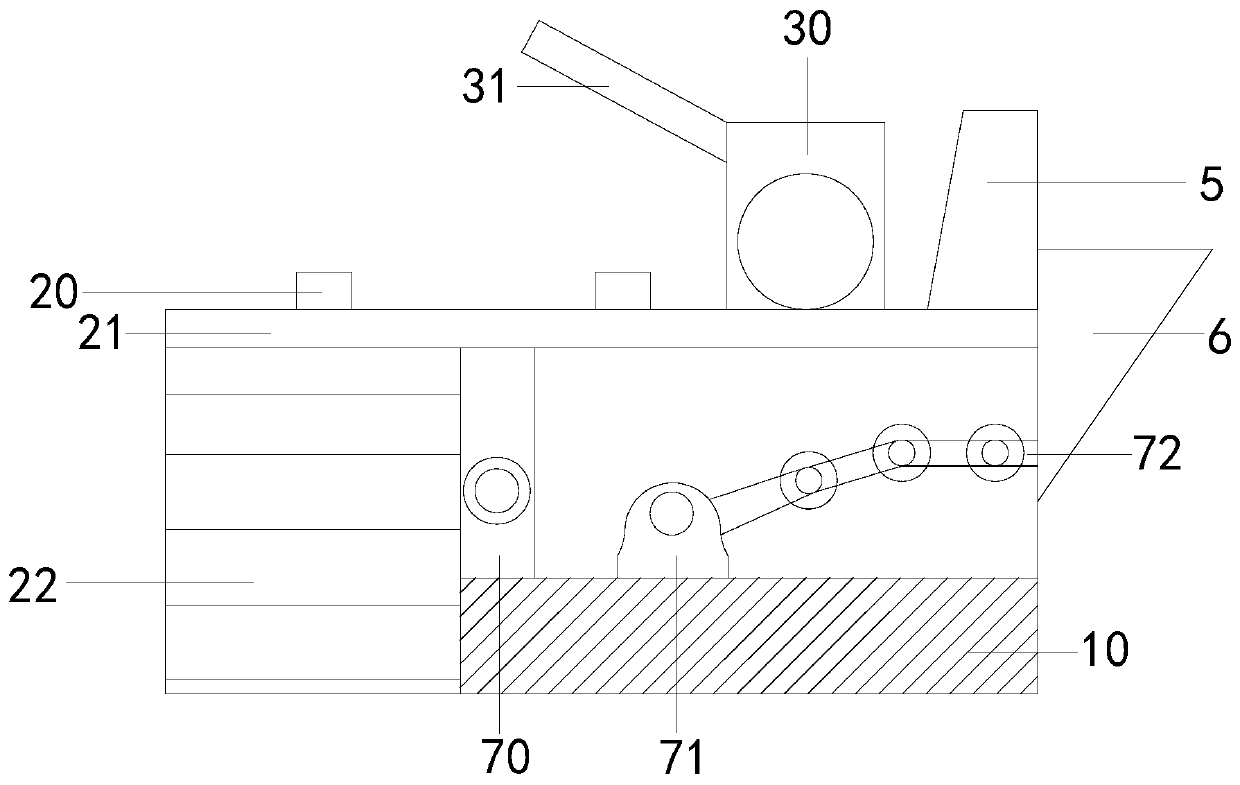

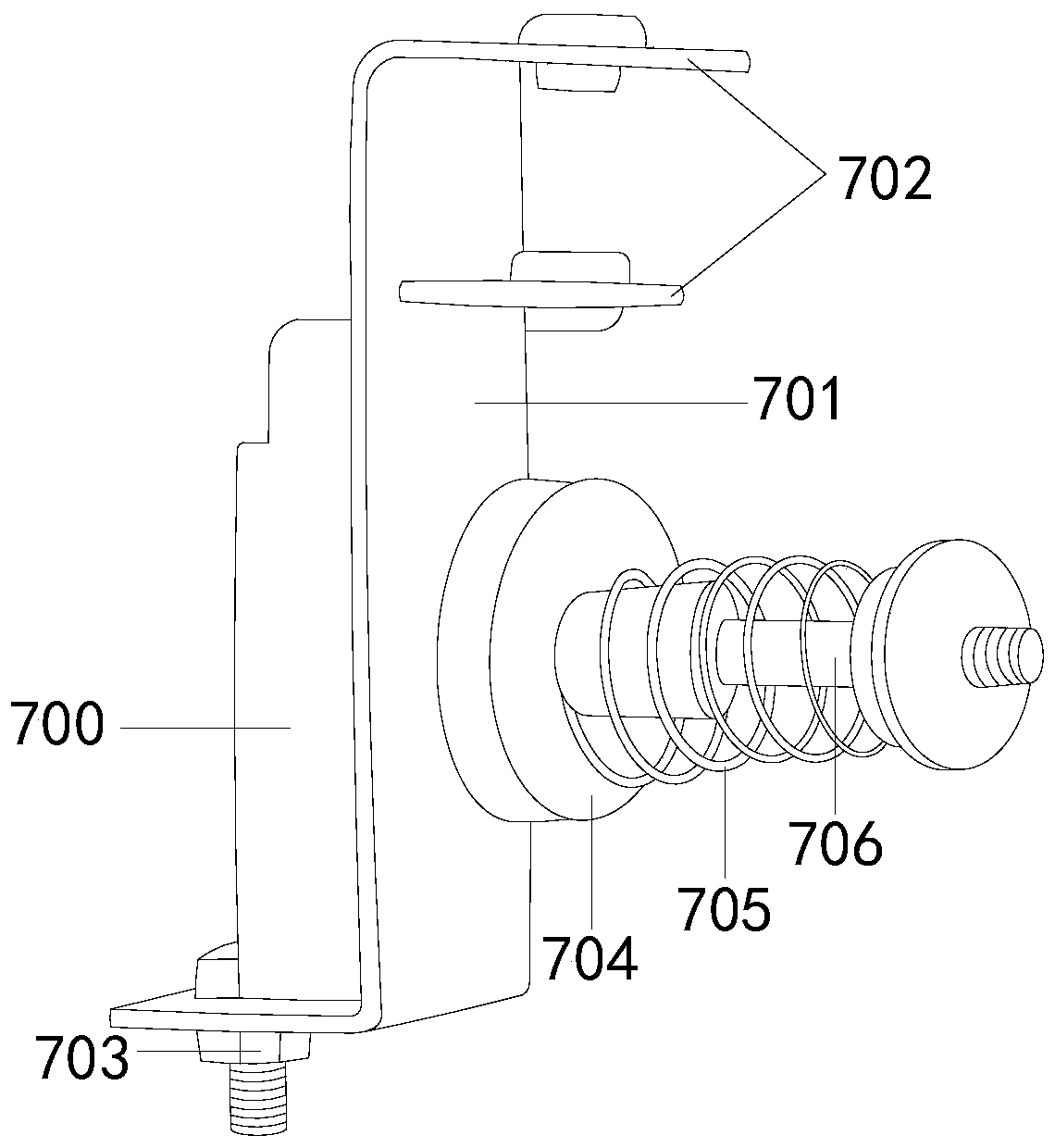

[0024] See figure 1 , The present invention provides a webbing automatic processing device, its structure includes: a main body 1, a conveying roller 2, a gripper 3, a motor 4, a radiator 5, a bucket guard 6, a weft grinding and cutting mechanism 7, and the machine The main body 1 is a rectangular parallelepiped structure. The top left side of the main body 1 is provided with a conveying roller 2. The conveying roller 2 is arranged on the left side of the main body 1 and connected to the clamp 3. The conveying roller 2 is rolling It will drive the webbing to move forward, so as to smoothly transport the webbing after the gripper 3 is shaped and gathered. The gripper 3 is located at the top of the main body 1 and is connected to the conveyor roller 2. The gripper 3 can be used to disperse The raw materials of the webbing are arranged and collected into a flat ribbon, which is convenient for later processing. There is a motor 4 between the grippers 3 and is connected to it. The mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com