Glass cutting device for glass production

A glass and glass plate technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve problems such as edge bursting, harsh production parameters, uneven force on glass, etc., to achieve improved work efficiency, good quality, and cutting smooth cut effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

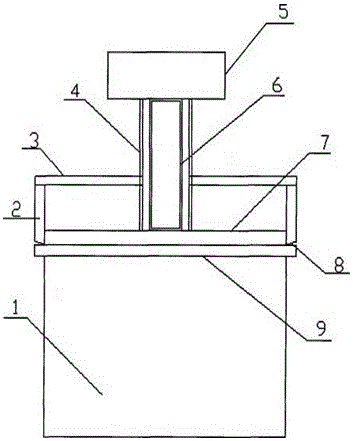

[0014] As shown in the drawings, the present invention includes an operating platform 1 loaded with a glass plate 9, a pressure plate 7 positioned above the glass plate 9, a lifting mechanism 5 connected with a pressure column 6 positioned above the glass plate 9, and a lifting mechanism 5 connected with a lifting platform. The cutting and lifting shaft 4 of the mechanism 5 is provided with a support 3 , and the support 3 is provided with a cutting column 2 for cutting the glass plate 9 outside the operating platform 1 .

[0015] The lower part of the cutting column 2 is provided with an inclined bottom plate 8 .

[0016] The number of the brackets 3 is two.

[0017] The number of the cutting columns 2 is two.

[0018] The operating platform 1 of the present invention is placed on a level ground or a suitable place, and a glass plate 9 to be cut is placed on the operating platform 1 , and part of the glass plate 9 to be cut is exposed outside the operating platform 1 . The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com