Lyocell/secondary cellulose acetate fiber blended fabric and weaving method thereof

A technology of diacetate fiber and blended fabrics, applied in the field of textile fabrics, can solve the problems of fabric loss of luster, poor alkali resistance, low strength of diacetate fibers, etc., and achieve low price, high loom weaving efficiency and wide application Effect

- Summary

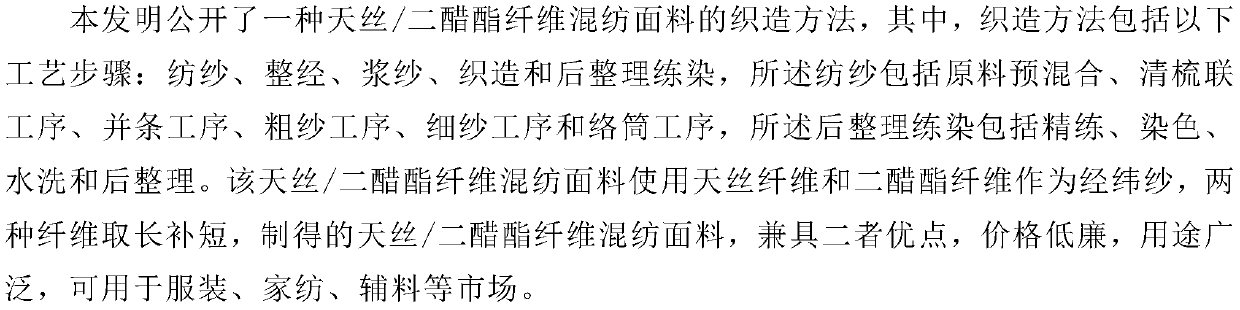

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

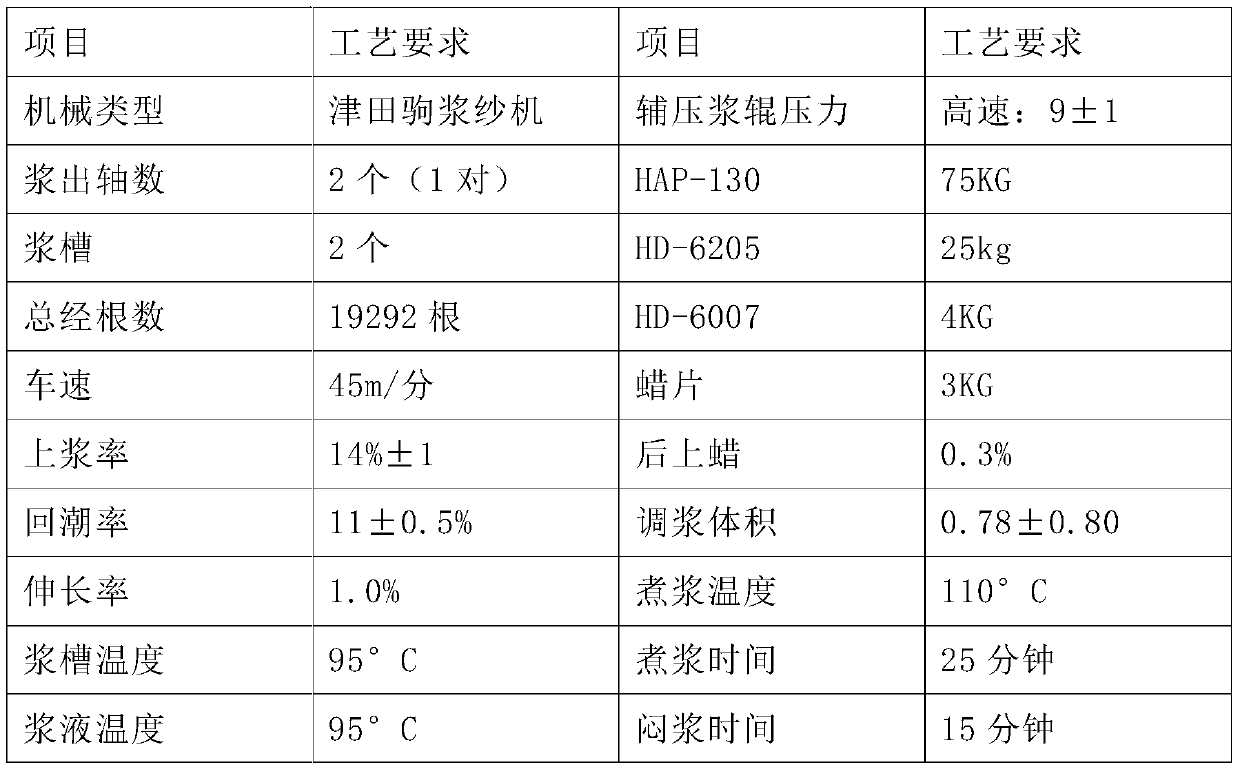

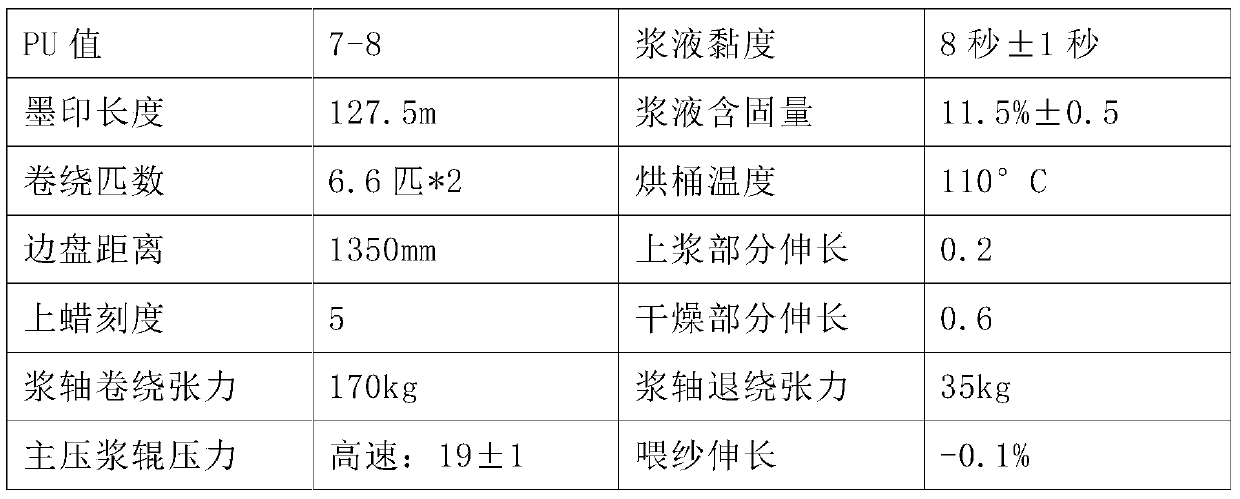

Method used

Image

Examples

Embodiment 1

[0032] In the weaving method of the Tencel / diecetate fiber blended fabric provided in this embodiment, the warp and weft yarns of the fabric are Tencel Saisen A100 produced by Austrian company and diacetate fiber blended yarn produced by Eastman Company of the United States.

[0033] Specifications of gray fabric: Saisen A100 ten70 / two vinegar 30 60*60s 182*116 106〞4 / 1.

[0034] Finished fabric specifications: Saisen A100 ten70 / two vinegar 30 60*60s 200*116 98〞4 / 1.

[0035] The specific process flow is as follows.

[0036] 1. Spinning

[0037] 1. Raw material premixing

[0038] In order to ensure that the two kinds of fiber raw materials with different characteristics can be fully mixed, to avoid color flowers due to different fiber dyeing properties, to alleviate the accumulation of diacetate fibers, and to prevent excessive short fibers in the post-production process, the two fibers are mixed together. Proportional portioning, weighing, layering, manual direct feeding and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com