Preparation method of magnesium-rare earth series alloy spectral standard sample

The technology of rare earth alloy and spectral standard sample is applied in the field of preparation of magnesium-rare earth alloy spectral standard sample. , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

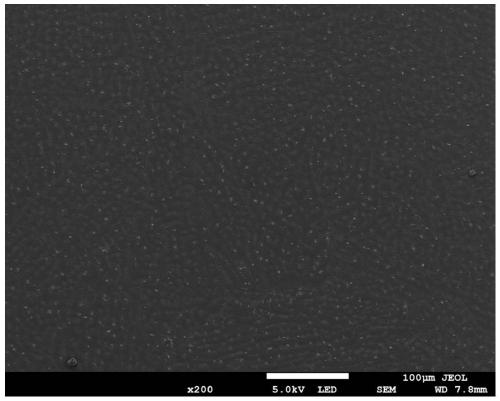

[0031] Embodiment 1: Mg-8Gd (wt.%) binary alloy spectral standard sample

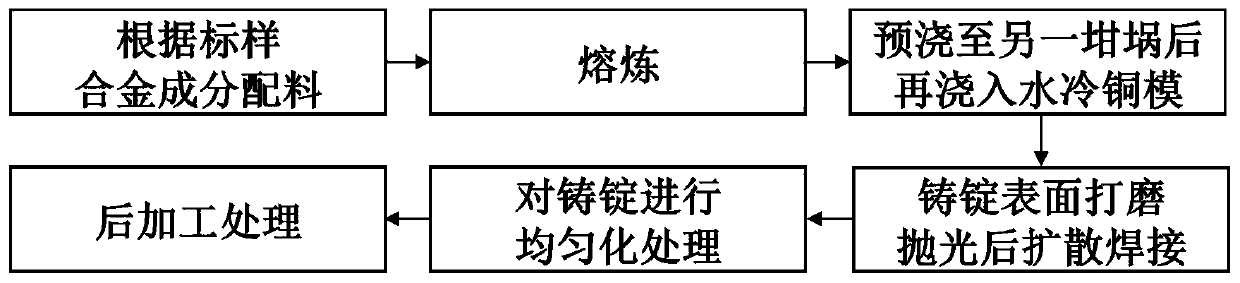

[0032] 1. Preparation of Mg-8Gd spectral standard sample

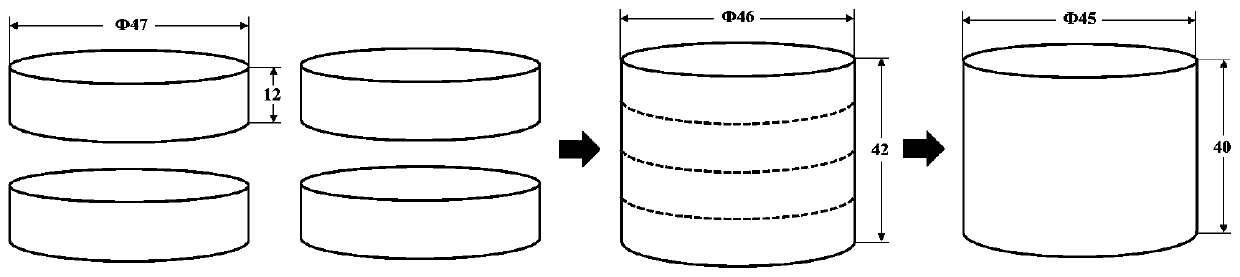

[0033] S1. Melting and casting a magnesium-rare earth alloy to obtain four Mg-8Gd binary alloy ingots with a diameter of Ф47 mm and a depth of 12 mm. Specific steps are as follows:

[0034] a. Prepare magnesium alloy and magnesium-rare earth master alloy according to the ratio of magnesium-rare earth alloy. When preparing pure magnesium ingots and Mg-20Gd (wt.%) intermediate alloy charge, the burning loss rate of Gd element should be considered reasonably when batching the ingredients. According to experience, the burning loss rate of Gd element is 8%.

[0035] b. First melt the pure magnesium ingot at 740°C and keep it warm for 20 minutes, then add the Mg-20Gd master alloy ingot into the pure magnesium melt and make the surface of the melt be covered with the master alloy material to prevent its oxidation and burning. Adjust the heating temp...

Embodiment 2

[0052] Embodiment 2: Mg-15Gd (wt.%) binary alloy spectral standard sample

[0053] 1. Preparation of Mg-15Gd spectral standard sample

[0054] S1. Melting and casting a magnesium-rare earth alloy to obtain four Mg-15Gd binary alloy ingots with a diameter of Ф47 mm and a depth of 12 mm. Specific steps are as follows:

[0055] a. Prepare magnesium alloy and magnesium-rare earth master alloy according to the ratio of magnesium-rare earth alloy. When preparing pure magnesium ingots and Mg-20Gd (wt.%) intermediate alloy charge, the burning loss rate of Gd element should be considered reasonably when batching the ingredients. According to experience, the burning loss rate of Gd element is 8%.

[0056] b. First melt the pure magnesium ingot at 760°C and keep it warm for 30 minutes, then add the Mg-20Gd master alloy ingot into the pure magnesium melt and make the surface of the melt be covered with the master alloy material to prevent its oxidation and burning. Adjust the heating t...

Embodiment 3

[0073] Embodiment 3: Mg-10Dy (wt.%) binary alloy spectral standard sample

[0074] 1. Preparation of Mg-10Dy spectral standard sample

[0075] S1. Melting and casting a magnesium-rare earth alloy to obtain four Mg-10Dy binary alloy ingots with a diameter of Ф47 mm and a depth of 12 mm. Specific steps are as follows:

[0076] a. Prepare magnesium alloy and magnesium-rare earth master alloy according to the ratio of magnesium-rare earth alloy. When preparing pure magnesium ingots and Mg-20Dy (wt.%) intermediate alloy charge, the burning loss rate of Dy element should be considered reasonably when batching ingredients, and the burning loss rate of Dy element should be 8% according to experience.

[0077] b. First melt the pure magnesium ingot at 740°C and keep it warm for 20 minutes, then add the Mg-20Dy master alloy ingot into the pure magnesium melt and make the surface of the melt be covered with the master alloy material to prevent its oxidation and burning. Adjust the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com