Special tool for heat treatment of shield hob ring and machining process thereof

A processing technology and a technology of a knife ring, applied in the field of tooling and its processing technology, can solve the problems of uneven heating of the knife ring, uneven hardness, low furnace loading, etc., and achieve the effect of ensuring uniform heating and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

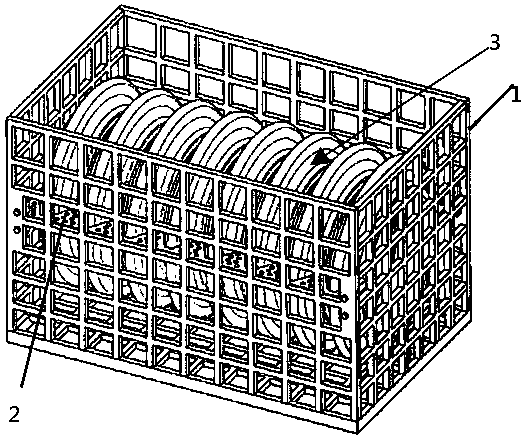

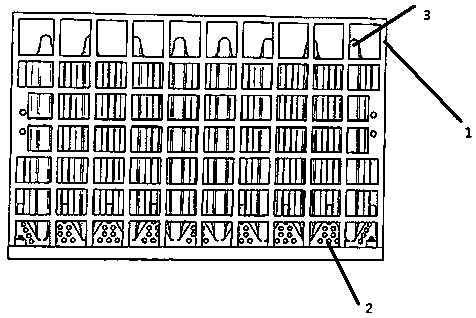

[0017] A special tooling for heat treatment of a shield hob cutter ring, which includes a housing 1, a hob cutter ring fixing frame 2 is installed at the bottom of the housing, and hob cutter ring fixing frames are respectively installed on both sides inside the housing 2;

[0018] The housing 1 described in this embodiment is a rectangular frame body, and ribs are arranged at intervals perpendicular to each other on the bottom surface and the vertical surface of the housing, and the two short beams on the bottom surface of the housing and the middle of the four long vertical columns on the vertical surface are provided with round holes for assembly. rectangular plate;

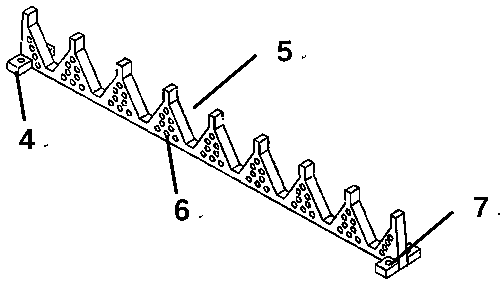

[0019] The hob cutter ring fixing frame 2 described in this embodiment is evenly distributed with grooves 5 matching the outer dimensions of the hob cutter ring, and fixing seats 4 are respectively provided at both ends of the shelf, and screw holes are opened on the fixing seats 7. The screw holes correspond...

Embodiment 2

[0025] The casing 1 and the hob cutter ring fixing frame 2 described in Embodiment 1 are all cast and formed by high temperature resistant nickel-based alloy.

[0026] The composition of its nickel-based alloy: C: 0.10%, Si: 1.00%, Mn: 1.00%, Cr: 18%, Ni: 48%, Al: 5%, S: 0.019%, P: 0.024%, the rest Fe .

Embodiment 3

[0028] The casing 1 and the hob cutter ring fixing frame 2 described in Embodiment 1 are all cast and formed by high temperature resistant nickel-based alloy.

[0029] The composition of its nickel-based alloy: C: 0.15%, Si: 0.8%, Mn: 0.8%, Cr: 16%, Ni: 45%, Al: 3%, S: 0.018%, P: 0.023%, the rest Fe .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com