Product quality testing device for different technological heating processes of hot-rolled steel billets

A technology of heating process and product quality, applied in the field of steel heat treatment, can solve the problem of inaccurate moisture content of wet mixture, and achieve the effect of ensuring accuracy, simple operation and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0026] The invention provides a product quality test device for hot-rolled billets in different process heating processes.

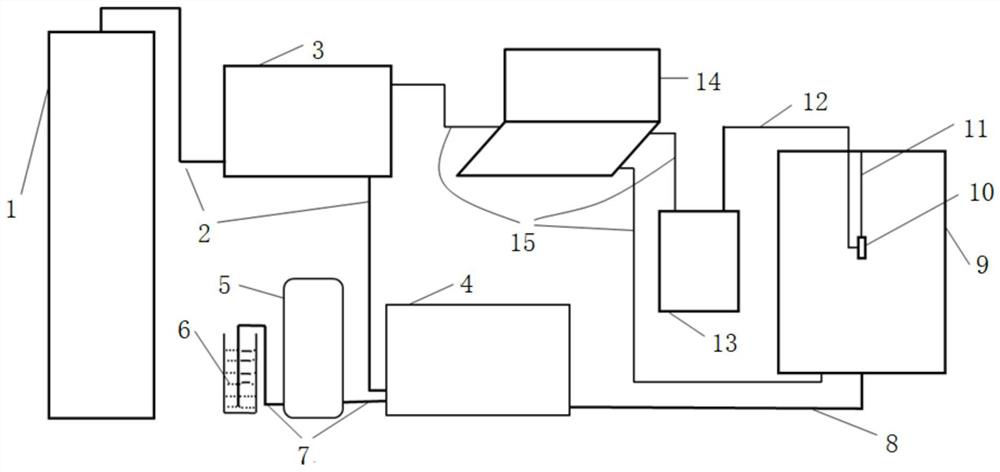

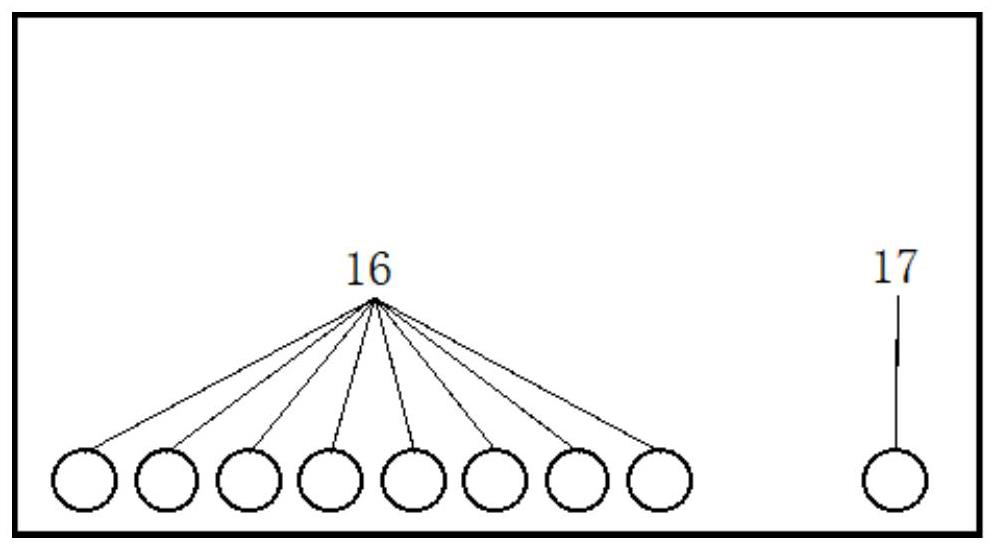

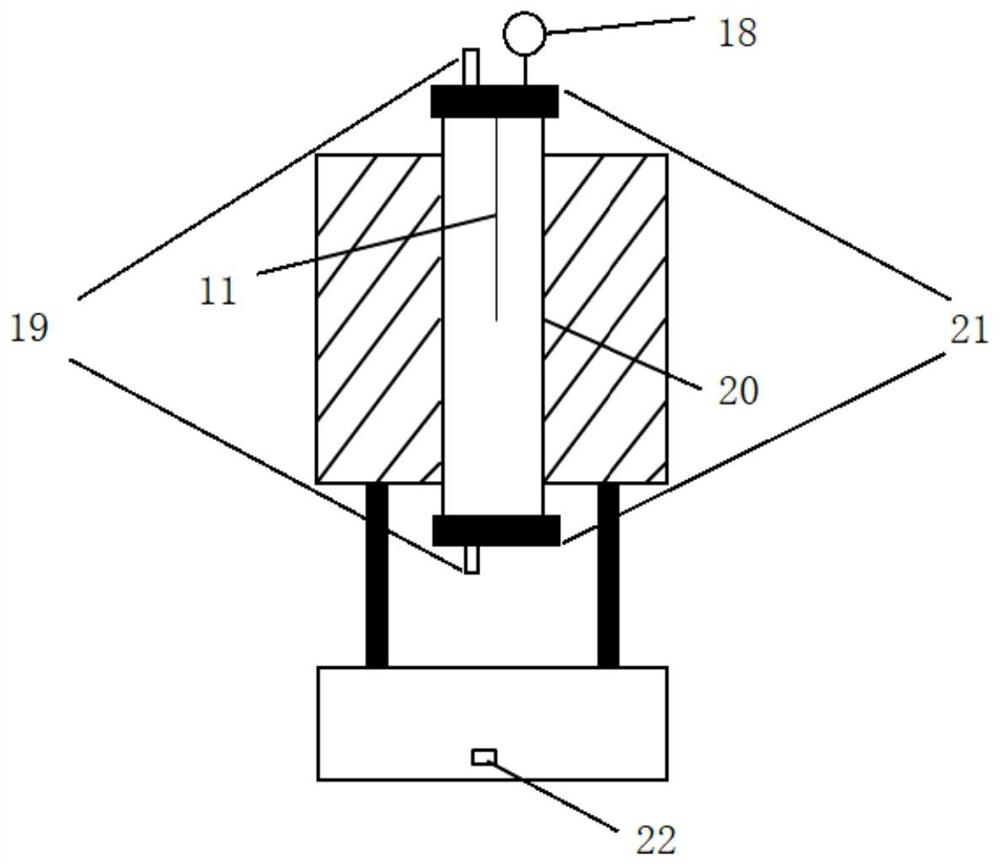

[0027] like figure 1 As shown, the device includes a precision multi-component gas distribution system 3, a double plunger pump 5, a steam generator 4, a tubular resistance furnace 9 and a temperature collector 13. The front end of the precision multi-component gas distribution system 3 passes through a gas distribution hose 2 Connect the high-pressure gas cylinder group 1, the precision multi-group gas distribution system 3 The rear end is connected to the steam generator 4 through the gas distribution hose 2; the liquid inlet of the steam generator 4 is connected to the deionized water 6 through the double plunger pump 5, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com