High temperature steam seed huller

A technology of high-temperature steam and solid peeling machine, which is applied in the direction of grain shelling, separating solids from solids with air flow, and shelling. High speed, less surface damage and low breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

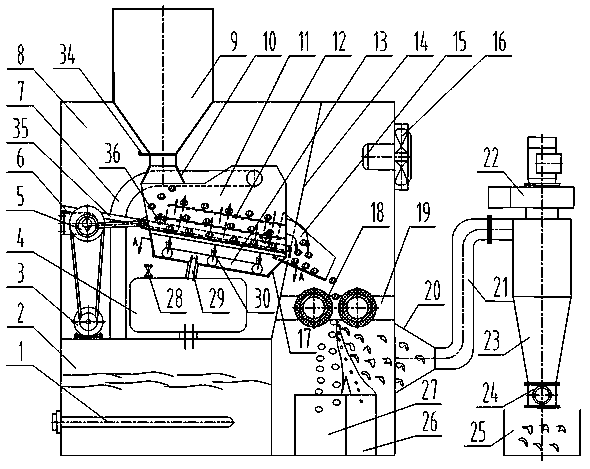

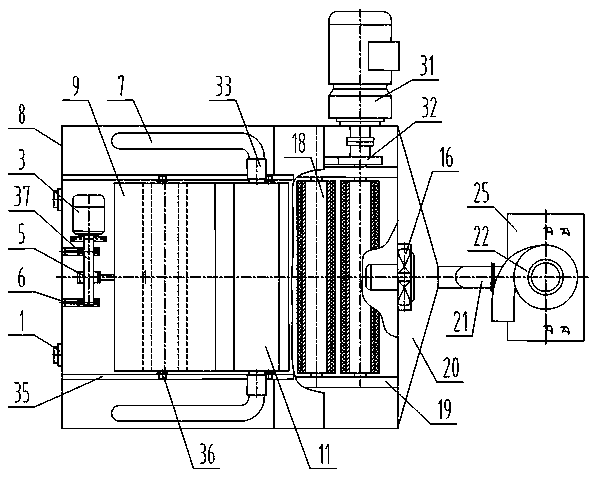

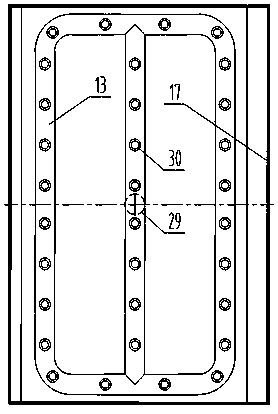

[0017] Such as figure 1 , figure 2 As shown, the structure schematic diagram of the high-temperature steam seed peeling machine of the present invention is provided, including a casing 8 and a peeling device arranged in the casing 8, and also includes a vibrating feeding device, a steam system, a winnowing system, and a partition 14 , steam exhaust fan 16, embryo box 26, seed core box 27, this dividing plate 14 is arranged in the casing 8, and this casing 8 is divided into the vibrating feeding chamber on the left side and the peeling chamber on the right side, the vibrating The feeding device and the steam system are arranged in the vibrating feeding chamber, the steam system is located below the vibrating feeding device, the peeling device is arranged in the peeling chamber, and the seed core box 27 and the germ box are arranged in sequence ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com