Peanut coat removing production system

A production system, peanut technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problem of high content of unpeeled peanuts, and achieve the effect of improving the peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

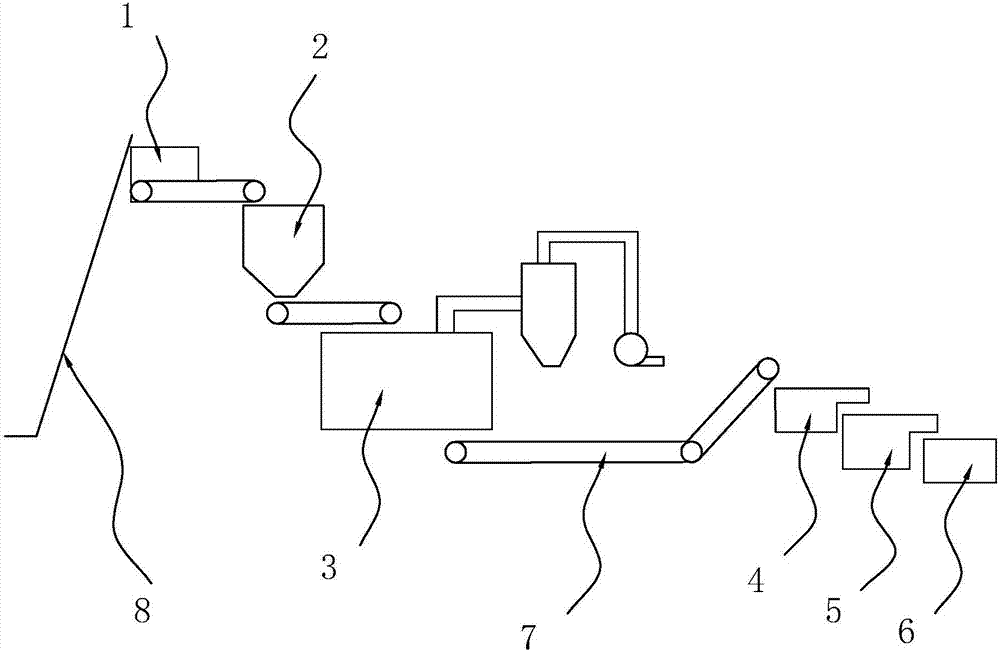

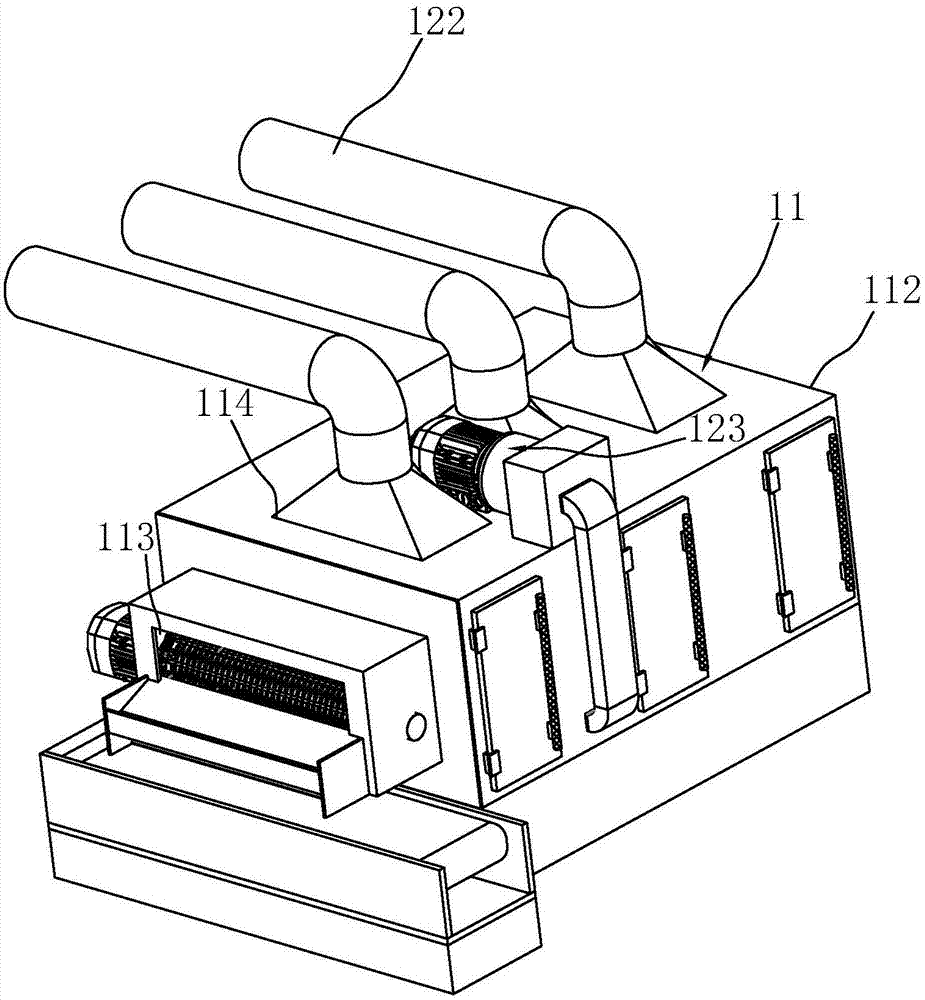

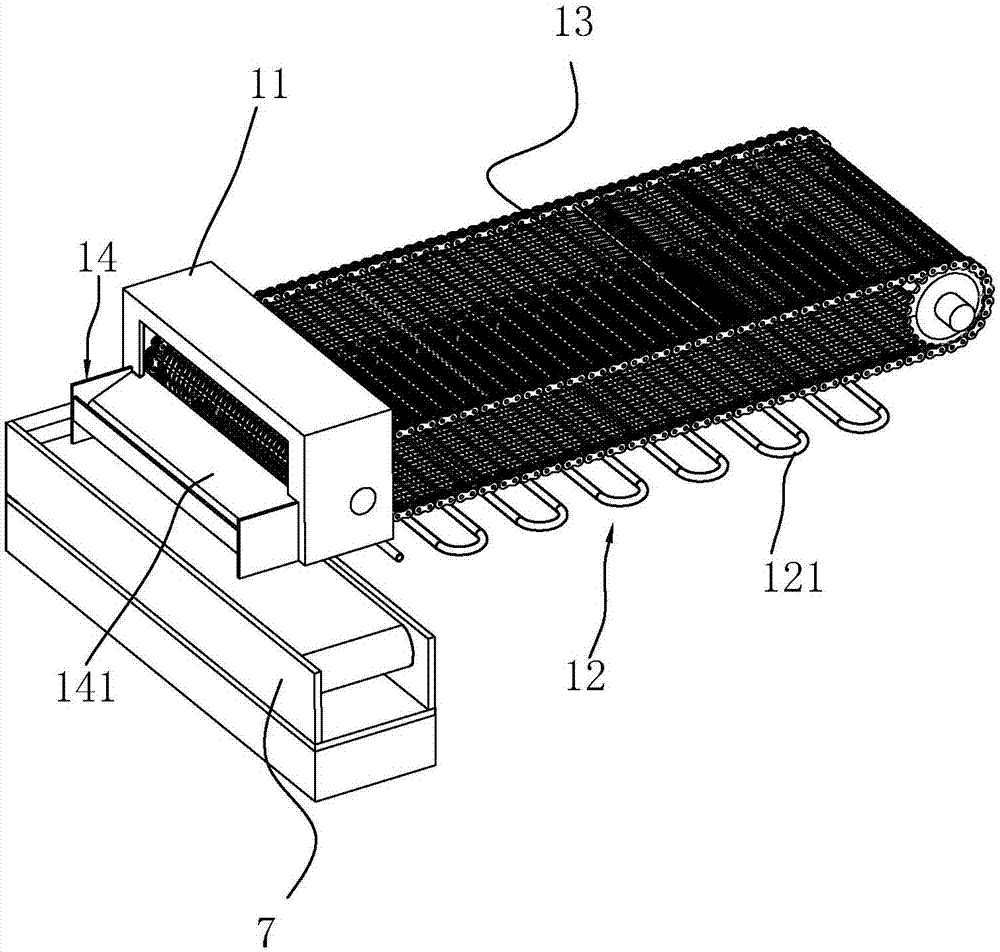

[0036] Embodiment: a kind of peanut peeling production system is used for peeling peanuts, see attached figure 1, the peanut peeling production system includes a peanut roasting machine 1, a storage bin 2, a peanut peeling machine 3, a peanut color sorter 4, a peanut screening machine 5 and a vacuum packaging machine 6 arranged in sequence, and each mechanism is carried out by a conveyor belt 7. For the transportation of peanuts, a lifting mechanism 8 is provided at the roasting inlet 112 at the front end of the peanut roasting machine 1 to lift the peanuts that need to be peeled into the roasting machine. Peanuts that need to be peeled are first put into the roaster for roasting. After roasting, they are sent from the roaster to the conveyor belt 7. The storage bin 2 is located under the roaster. The conveyor belt 7 can directly send the peanuts to the Cooling is carried out in the storage bin 2 until it cools to room temperature, the peanut peeling machine 3 is located under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com