Intelligent separation equipment and separation method for peanut kernels and peanut skin

A technology of peanut red coat and separation device, which is applied in the fields of shelling, food processing, and pod removal, etc., can solve problems such as damage, oil quality and human health impact, and changes in material nutrients.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

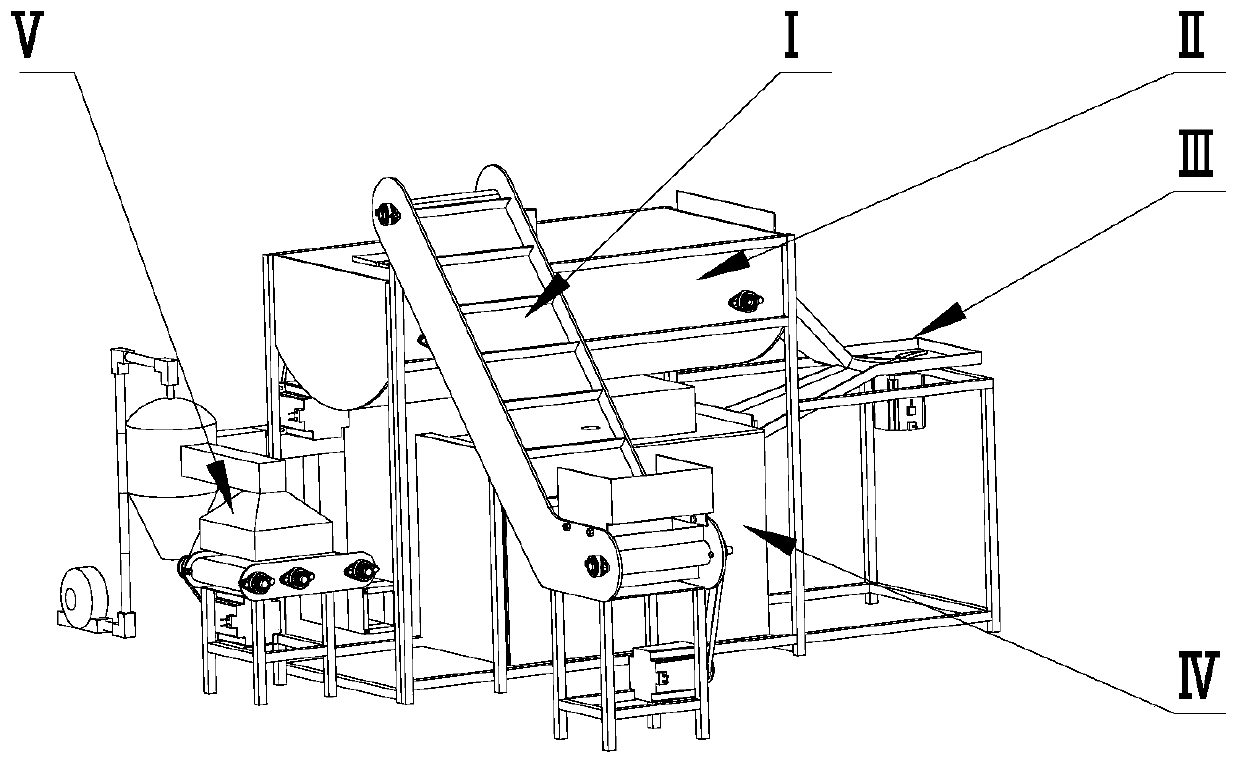

[0054] This embodiment discloses an intelligent separation device for peanut kernels and peanut red coats. figure 1 As shown, it includes the feeding device I fixed on the frame, the gas explosion device II, the toggle device III, the drying device IV, and the negative pressure adsorption device V. The gas explosion device is arranged behind the conveying device, the toggling device is located at the subsequent part of the gas explosion device, the drying device is located at the subsequent processing link of the toggling device, and the collecting device is arranged at the rear of the drying device.

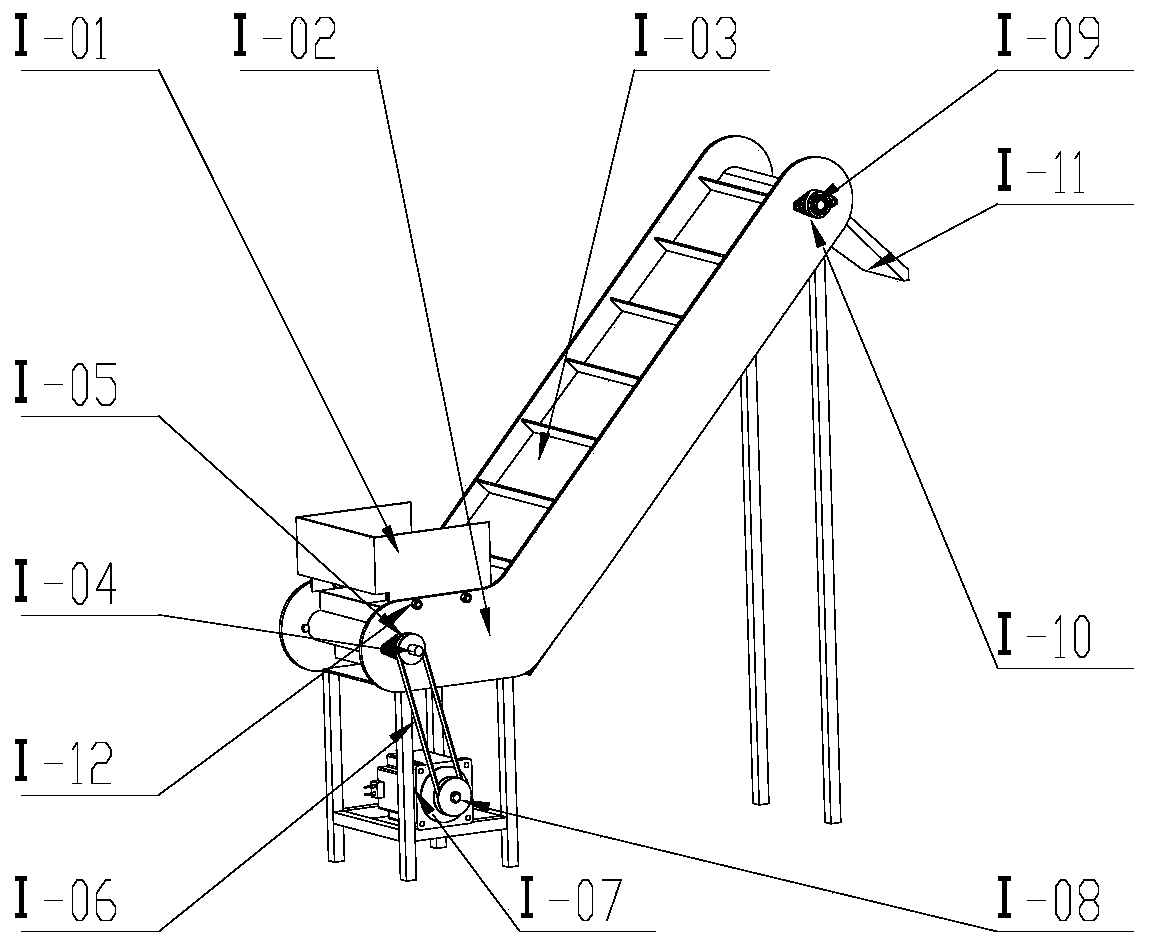

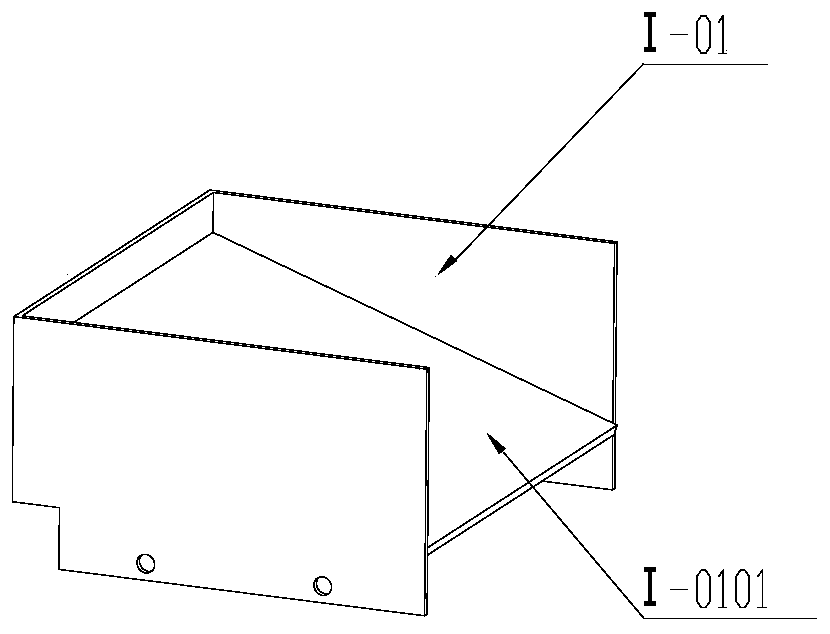

[0055] In a specific implementation example, the structure of the feeding device is shown in accompanying drawing 2 (a), and the feeding device includes a feeding device 1-01, a flexible conveyor belt 1-03, a driving part, and the tail portion of the flexible conveyor belt is provided with a feeding slide 1 -11, the two sides of the flexible conveyor belt are provided with trans...

Embodiment 2

[0097] The purpose of this embodiment is to provide the intelligent separation method of peanut kernels and peanut red coats, including:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com