Modified perovskite type catalyst and preparation method thereof

A perovskite-type catalyst technology, applied in chemical instruments and methods, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problems of low-temperature catalytic activity and limitations of perovskite-type catalysts, and achieve The effect of low operating cost, ease of industrial application, and increased catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of modified perovskite type catalyst is characterized in that, comprises the following steps:

[0026] (1) Mix the metal salt of A and the metal salt of M according to the molar ratio of A and B in the ratio of 1:0.8 to 1:1.2, load them on the carrier according to the sol-gel method, dry and roast, and prepare ABO 3 Perovskite materials;

[0027] (2) immersing the perovskite catalytic material prepared in step (1) in an acidic solution;

[0028] (3) The material obtained in step (2) is washed with distilled water or deionized water, and when the pH is neutral, it is placed in an oven for drying, and the obtained material is a modified perovskite catalyst.

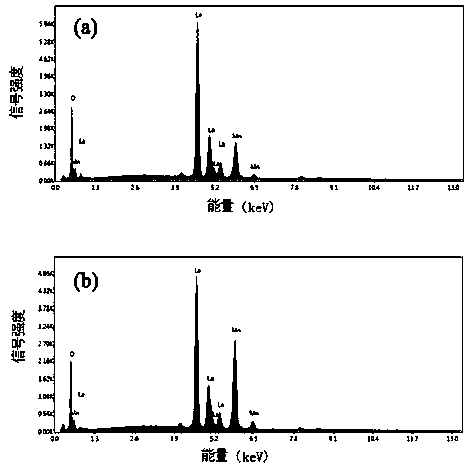

Embodiment 1

[0030] A modified perovskite catalyst, the modified perovskite catalyst is ABO 3 structure, where A is La 1-x m x , x=0, B bit is Mn.

[0031] A preparation method of a modified perovskite catalyst, comprising the following steps:

[0032] (1) Preparation of LaMnO supported on cordierite by sol-gel method 3 Perovskite. Take La(NO 3 ) 2 .6H 2 O11.5g, the weight fraction is 50% Mn(NO 3 ) 2 9.5g, citric acid 1.7g, add 7g of deionized water. Cook it in a water bath at 60°C to make it appear as a sol, then place the cordierite carrier in the sol, take it out and dry it, dry it at 105°C for 6 hours, and then bake it at 700°C for 4 hours. then prepared LaMnO 3 perovskite materials.

[0033] (2) LaMnO prepared in step (1) 3 Perovskite soaked in 3M HNO 3 solution, the duration is 20min.

[0034] (3) Rinse the modified material obtained in step (2) with distilled water or deionized water. When the pH is neutral, then place the material in an oven and dry it at 130°C for ...

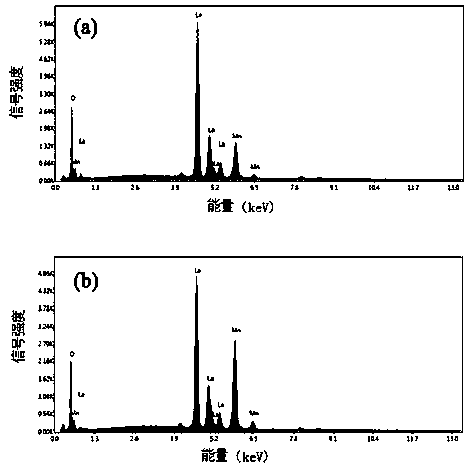

Embodiment 2

[0038] A modified perovskite catalyst, the modified perovskite catalyst is ABO 3 structure, where A is La 1-x m x , x=0, B bit is Co.

[0039] A preparation method of a modified perovskite catalyst, comprising the following steps:

[0040] (1) Preparation of LaCoO supported on alumina by sol-gel method 3 Perovskite. Take La(NO 3 ) 2 .6H 2 O11.5g, Co(NO 3 ) 2 .6H 2 O 7.7g, citric acid 1.7g, add deionized water 7g. Cook in a water bath at 60°C to make it appear as a sol, then place the alumina carrier in the sol, take it out and dry it, dry it at 120°C for 10 hours, and then bake it at 500°C for 6 hours. then prepare LaCoO 3 perovskite materials.

[0041](2) LaCoO prepared in step (1) 3 The perovskite was soaked in 3M glacial acetic acid solution for 80min.

[0042] (3) Rinse the modified material obtained in step (2) with distilled water or deionized water. When the pH is neutral, then place the material in an oven and dry it at 60°C for 5 hours. The obtained mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com