Air purification composition containing diatom pure negative ion particles and preparation method of composition

A technology of negative ion particles and air purification, applied in the field of air purification, can solve the problems of leakage of filling materials, cumbersome control, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

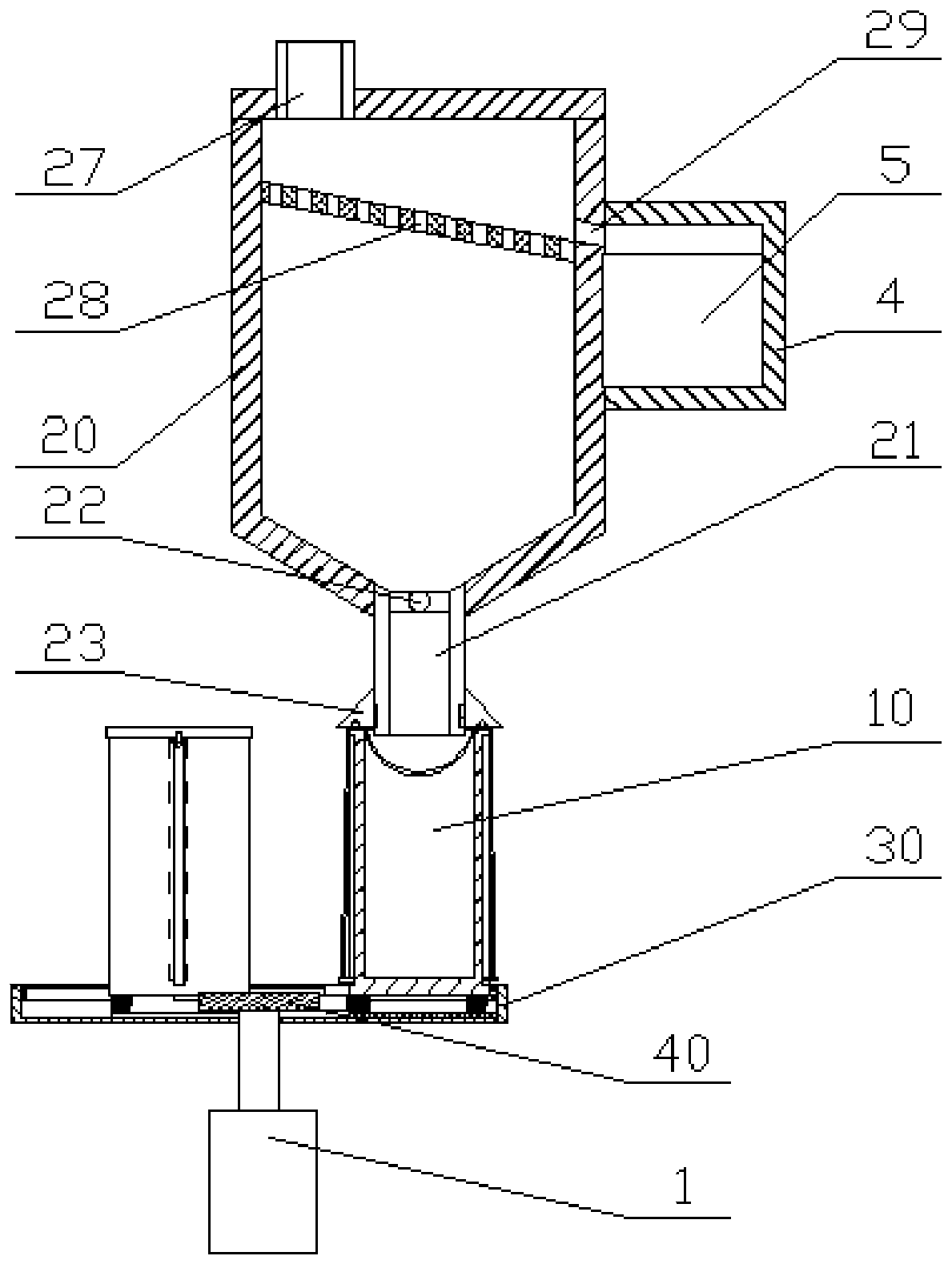

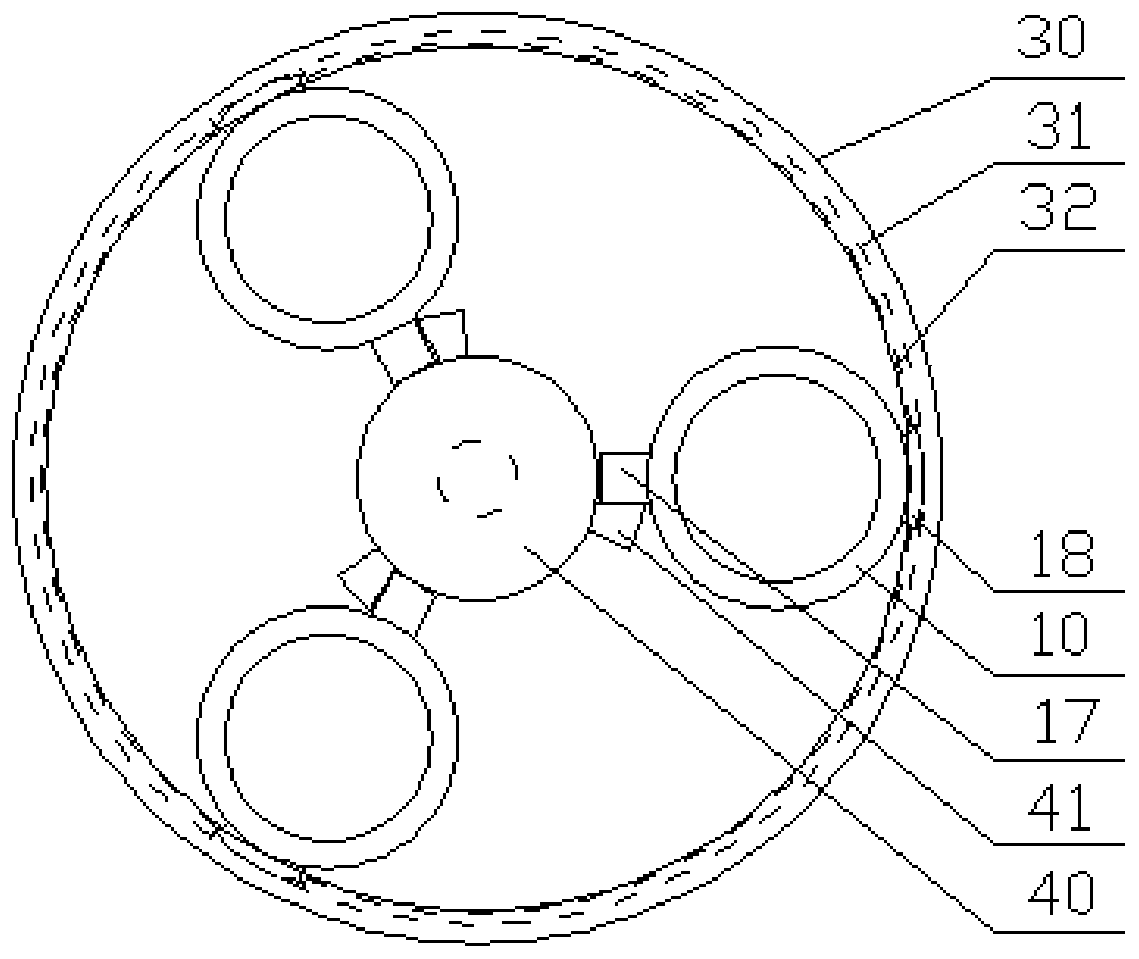

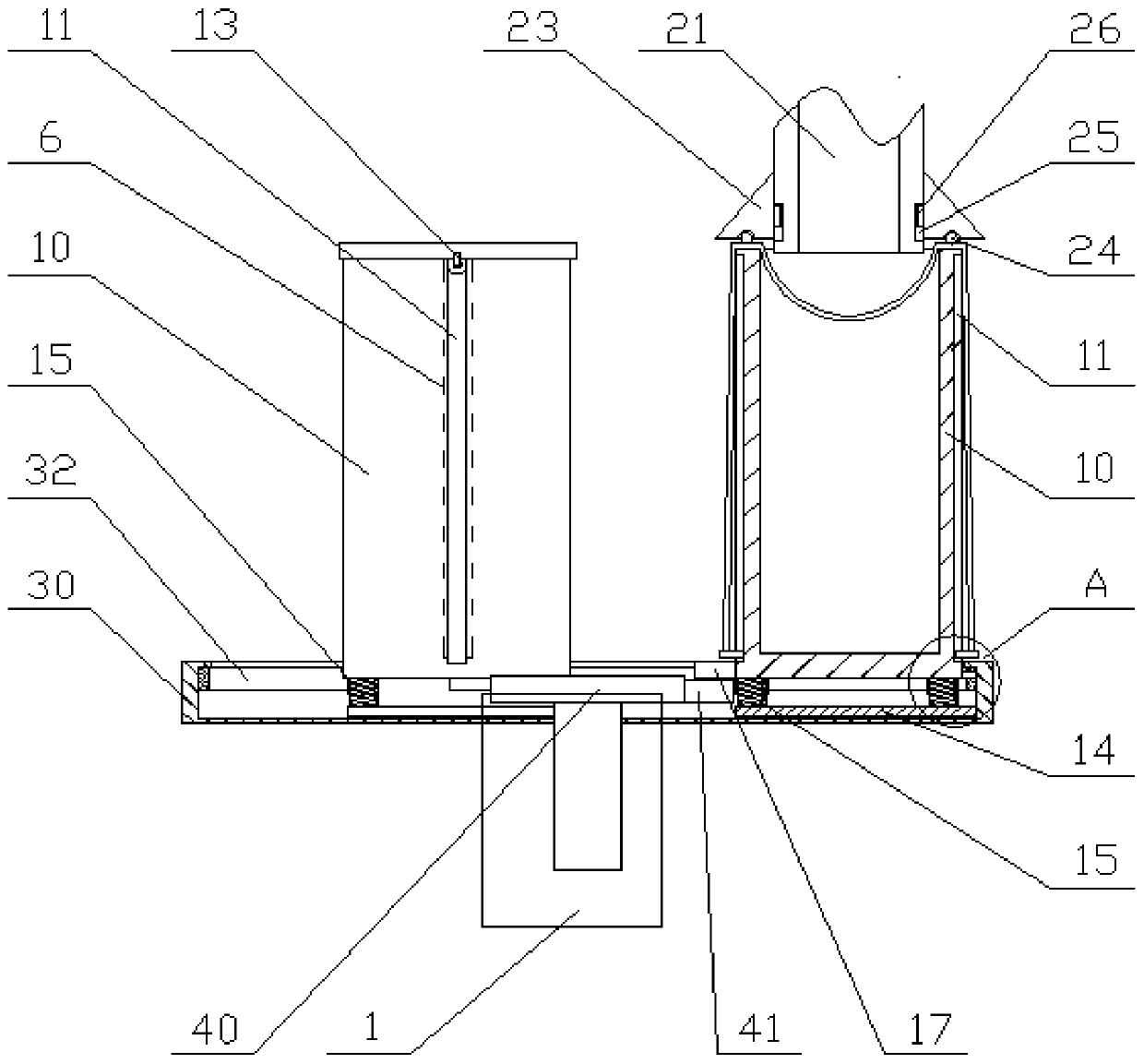

Image

Examples

Embodiment 1

[0065] An air purification composition containing diatom pure negative ion particles, including a first component and a second component, the raw material components of the first component include diatom pure negative ion particles, and the diatom pure negative ion particles include The following raw material components in parts by weight: 40 parts of diatomite, 18 parts of tourmaline, and 8 parts of nano photocatalyst; the second component includes the following raw material components in parts by weight: 8 parts of photocatalyst, CLO purification factor 6 22 parts of sepiolite, 40 parts of attapulgite, and 23 parts of diatomite; the mass ratio of the first component to the second component is 4:1.

[0066] The preparation method of the above-mentioned air purification composition containing diatom pure negative ion particles is as follows:

[0067] 1. The preparation of the first component comprises the steps of:

[0068] A1: Select diatomite material with adsorption capaci...

Embodiment 2

[0109] An air purification composition containing diatom pure negative ion particles, including a first component and a second component, the raw material components of the first component include diatom pure negative ion particles, and the diatom pure negative ion particles include The following raw material components in parts by weight: 35 parts of diatomite, 20 parts of tourmaline, and 9 parts of nano photocatalyst; the second component includes the following raw material components in parts by weight: 6 parts of photocatalyst, CLO purification factor 8 25 parts of sepiolite, 35 parts of attapulgite, and 25 parts of diatomite; the mass ratio of the first component and the second component is 3:1.

[0110] The preparation method of the above-mentioned air-purifying composition containing diatom pure negative ion particles is the same as in Example 1.

[0111] In the above step three, a small particle bagging device is used, and its structure and function process are the sam...

Embodiment 3

[0114] An air purification composition containing diatom pure negative ion particles, including a first component and a second component, the raw material components of the first component include diatom pure negative ion particles, and the diatom pure negative ion particles include The following raw material components in parts by weight: 45 parts of diatomite, 15 parts of tourmaline, 6 parts of nano photocatalyst; the second component includes the following raw material components in parts by weight: 9 parts of photocatalyst, CLO purification factor 5 20 parts of sepiolite, 45 parts of attapulgite, and 20 parts of diatomaceous earth; the mass ratio of the first component and the second component is 4:1.

[0115] The preparation method of the above-mentioned air-purifying composition containing diatom pure negative ion particles is the same as in Example 1.

[0116] In the above step three, a small particle bagging device is used, and its structure and function process are th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com