Multilayer adhesive article

A multi-layer product, adhesive layer technology, applied in the direction of adhesive products, adhesive types, ester copolymer adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

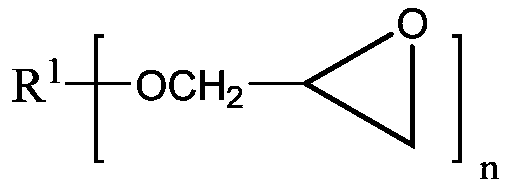

Image

Examples

Embodiment

[0138] Example

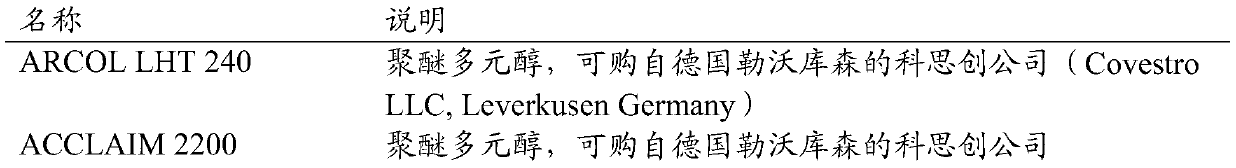

[0139] Material

[0140]

[0141]

[0142]

[0143] The acrylic mixtures listed in Table 1 were prepared for compounding experiments. Acrylic mixtures M1 and M2 were prepared according to method A. This method represents that proposed by Hamer (US5804610). Acrylic mixture M3 was prepared according to method B.

[0144] Table 1

[0145]

[0146] Curable layers L1-L5 as listed in Table 2 were prepared using acrylic mixtures M1-M3. Curable layers L1 and L2 were prepared according to method C. Curable layers L3 and L4 were prepared according to method D. Curable layer L5 was prepared according to method E.

[0147] Using Method F, test specimens were prepared for the measurement of tensile modulus (E'), stress at maximum load (σ max load ) and elongation. Test specimens were prepared for the Parallel Torque Adhesion Test according to Method G, using the total energy listed in Table 2 to initiate cure. The adhesion properties of curable l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com