A method for locating the shear failure position of rock structure plane in direct shear test

A technology of shear failure and positioning method, which is applied in the field of rock and soil mechanics, can solve the problems of damage acoustic emission source positioning, large positioning error, and inability to locate and analyze, and achieve high monitoring accuracy, high processing effectiveness, and fast search speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

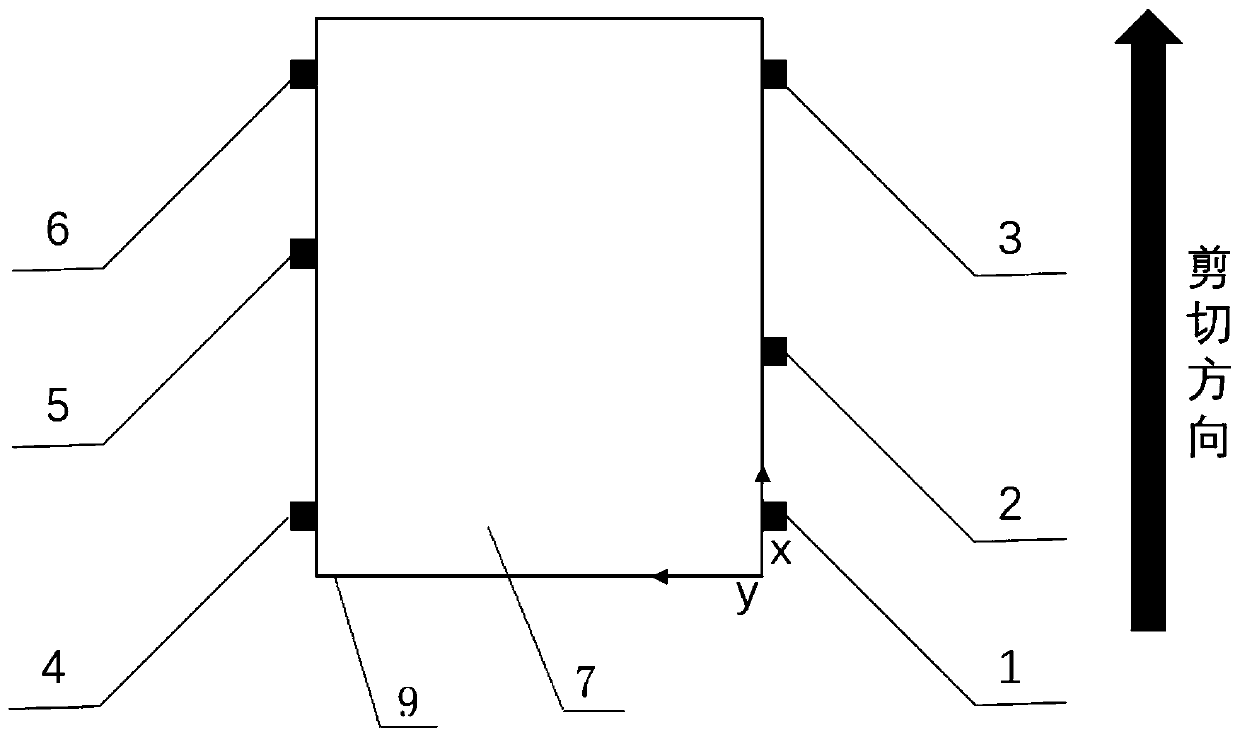

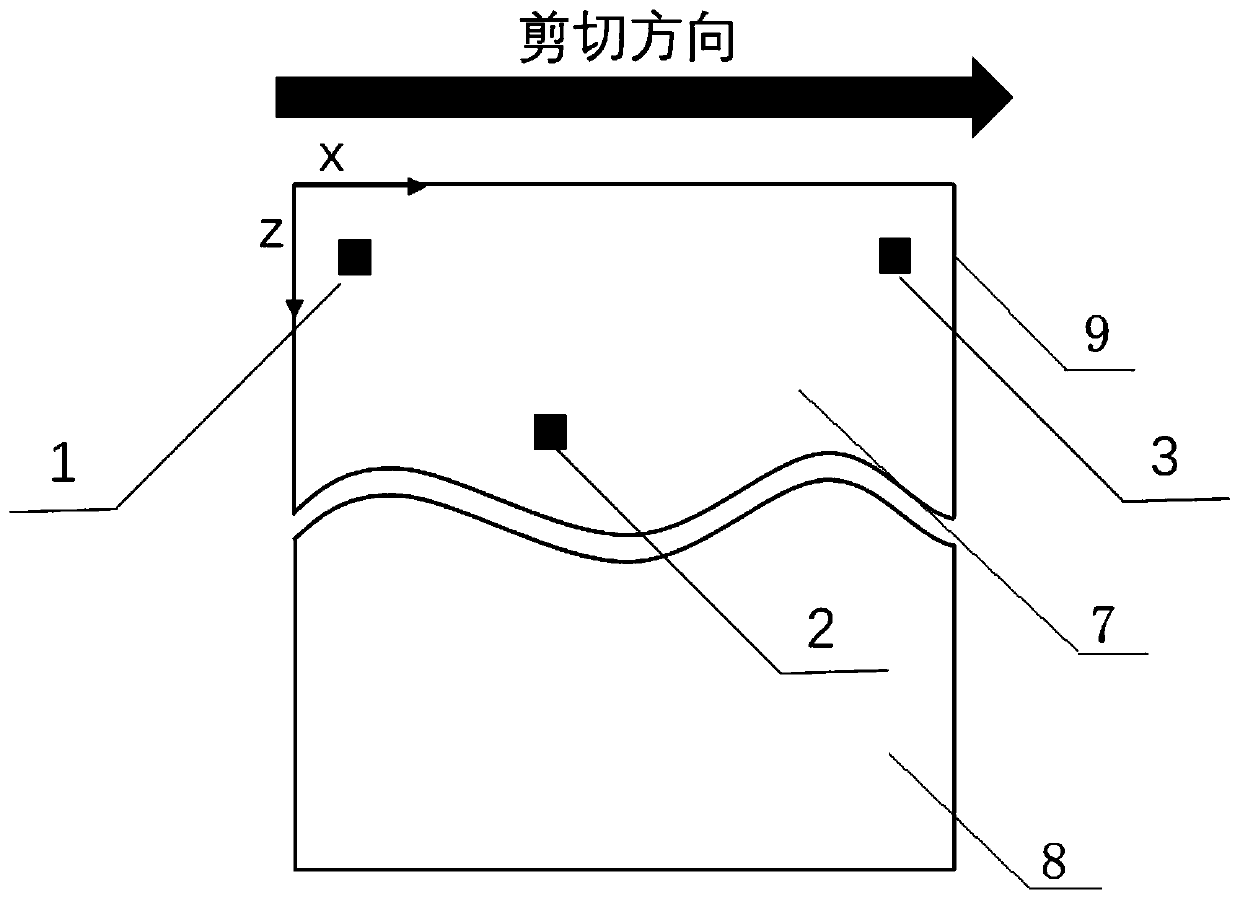

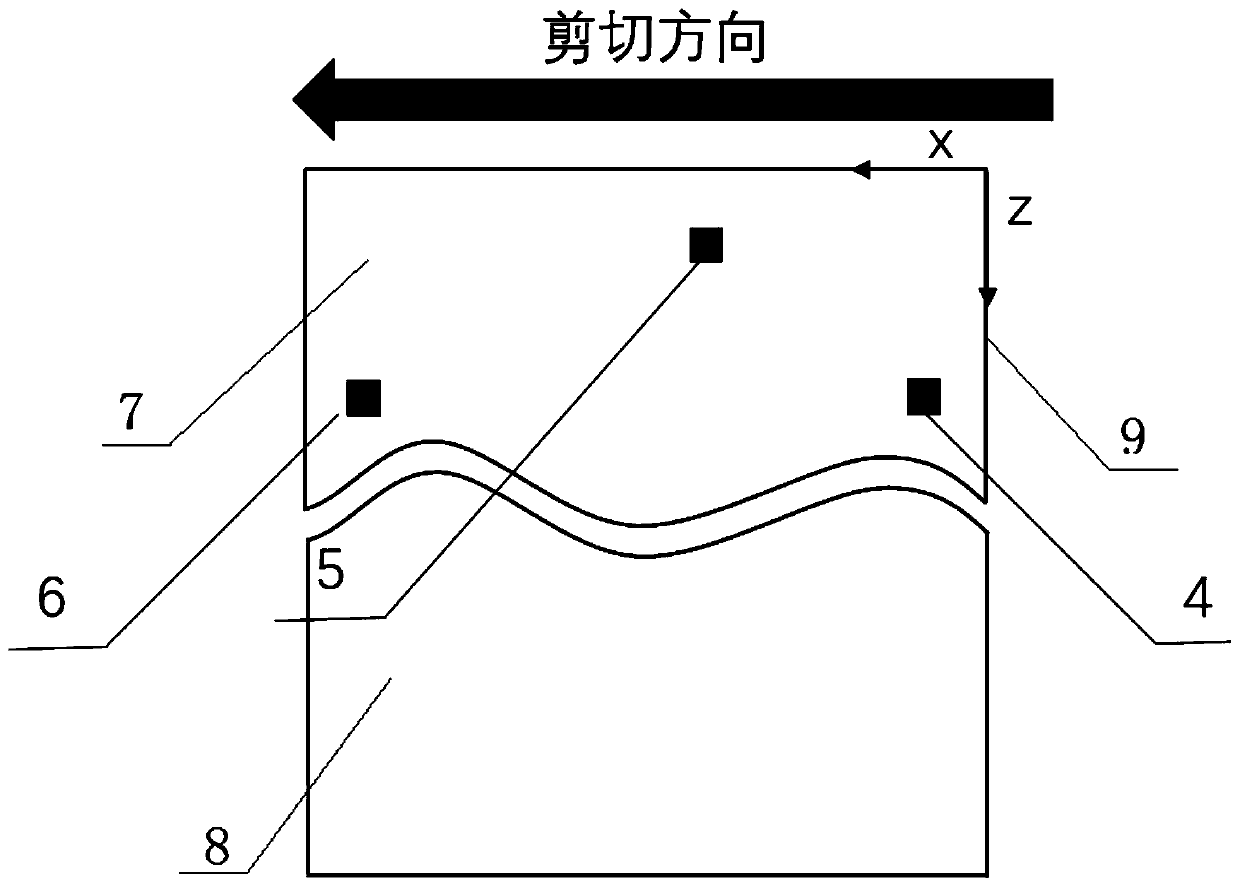

[0061] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , to further describe in detail the method of the present invention for locating the shear failure position of a block on a structural surface by using acoustic emission.

[0062] The present invention adopts acoustic emission to locate the optimization method of the block shear damage position on the structural surface comprising the following steps:

[0063] (1) Experimental test block 10 is processed into a cuboid test block of 150*120*150mm, such as figure 2 As shown, a total of two test blocks are divided into an upper block 7 and a lower block 8, and the upper block 7 and the lower block 8 are assembled into a cuboid of 150*120*150 mm. The contact surface of the upper and lower blocks is made close to the natural structure surface, which can be closely fitted.

[0064] (2) if figure 1 For the top view of the upper block 7, six acoustic emission sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com