Dumbbell-shaped pressure-point composite non-woven fabric and processing device and technology thereof

A dumbbell-shaped, non-woven fabric technology, applied in the field of raw materials for hygiene products, can solve problems such as small adhesion area, insufficient peeling force between product layers, anti-reverse seepage ability and infiltration ability cannot be guaranteed, and achieve increased Adhesive area, good anti-reverse seepage ability and infiltration ability, good three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

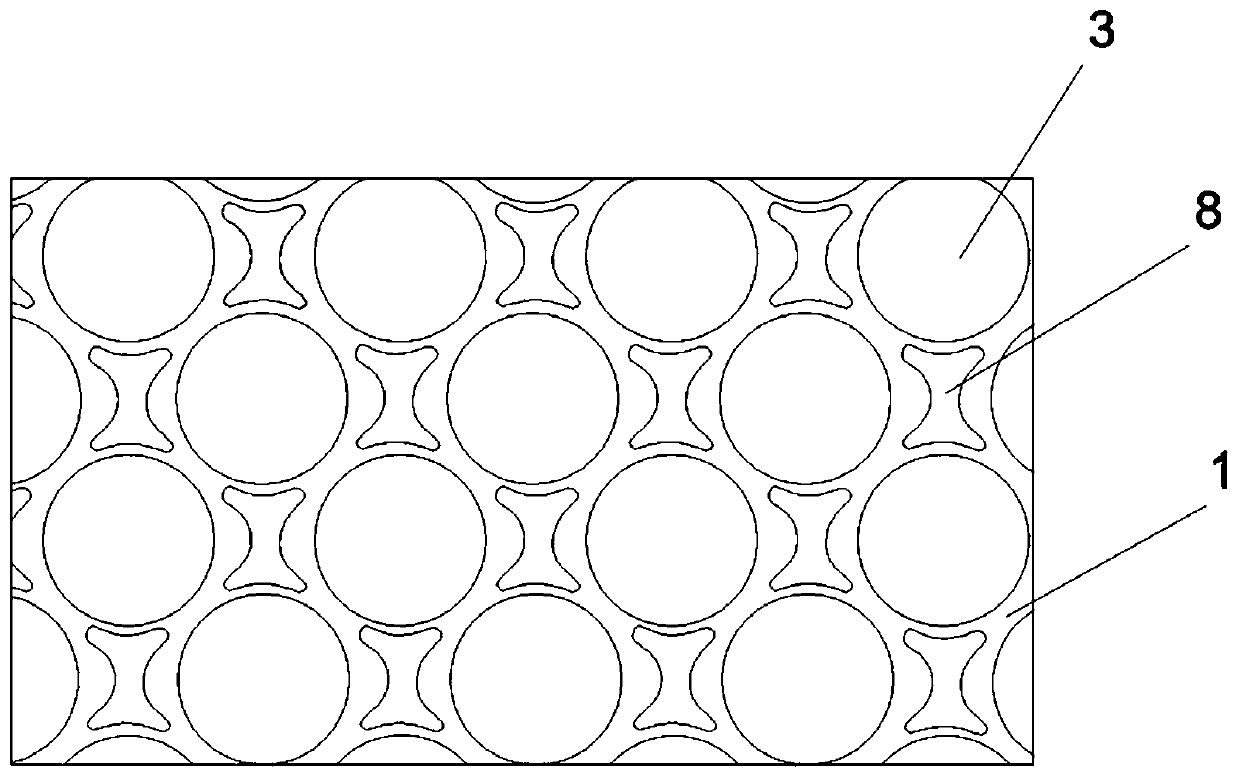

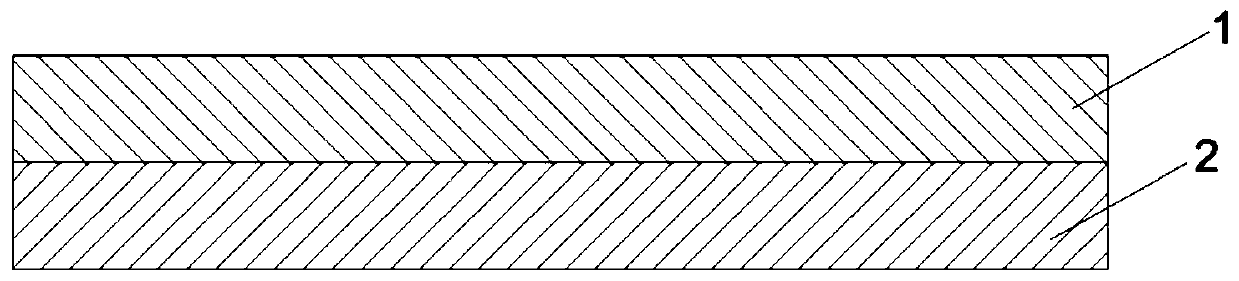

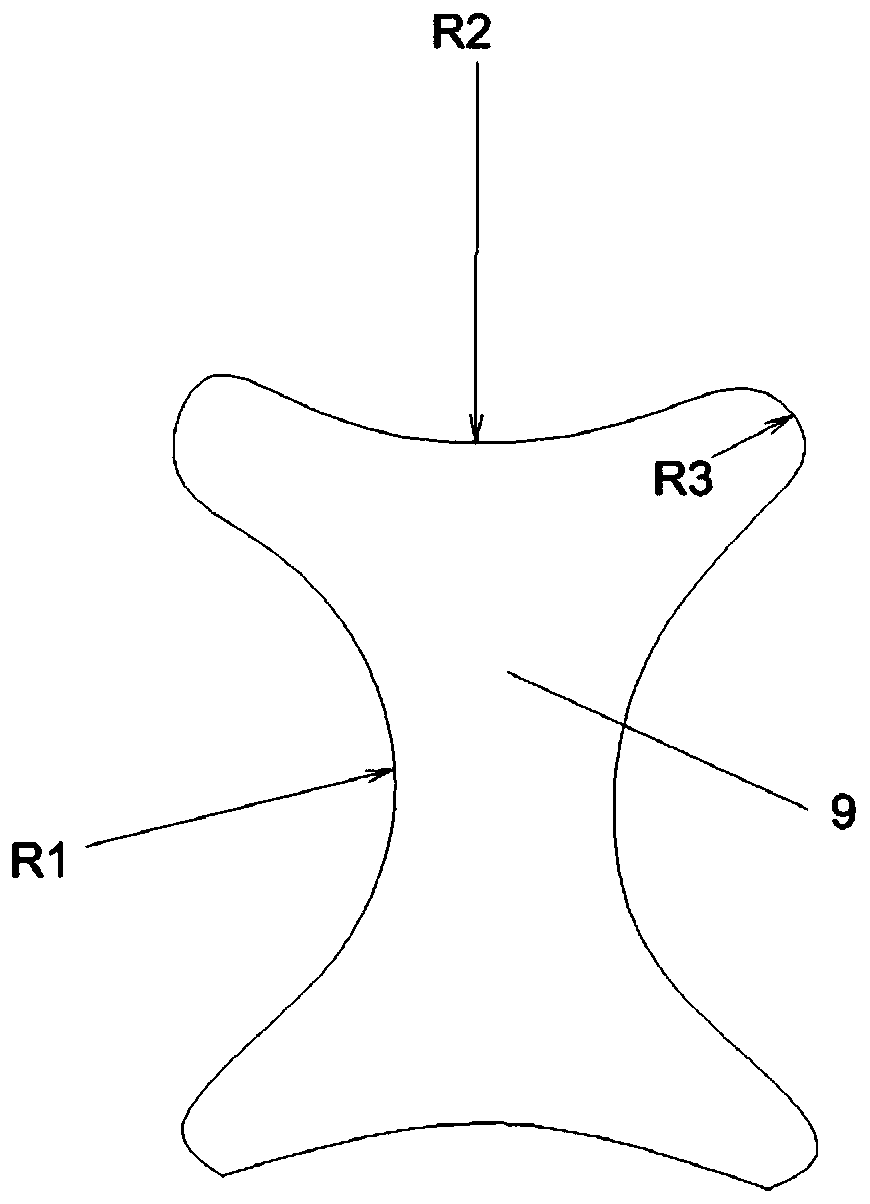

[0024] Such as Figure 1-3 As shown, a dumbbell-shaped pressure point composite non-woven fabric includes a composite surface layer 1 and a bottom layer 2, the surface layer 1 is a hot-air non-woven fabric, and the bottom layer 2 is a hot-air non-woven fabric. Ultrasonic thermal bonding and embossing through dumbbell-shaped flat points 9, and after ultrasonic thermal bonding between the surface layer 1 and the bottom layer 2, several pearl-shaped bumps 3 are formed, and between the surface layer 1 and the bottom layer 2 through dumbbell-shaped After the flat point 9 is embossed, several dumbbell-shaped shaping points 8 are formed, and there is a dumbbell-shaped shaping point 8 between every four adjacent pearl-shaped swelling points 3 . The length*width of the dumbbell-shaped shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com