A kind of preparation method of absorbent product

A technology for absorbent and absorbent articles, applied in the field of sanitary product production, can solve the problems of inability to monitor and detect in real time, large error in the amount of blanking, etc., and achieve the effect of reducing the flow of unqualified products into the market, reducing waste, and improving the utilization rate of production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

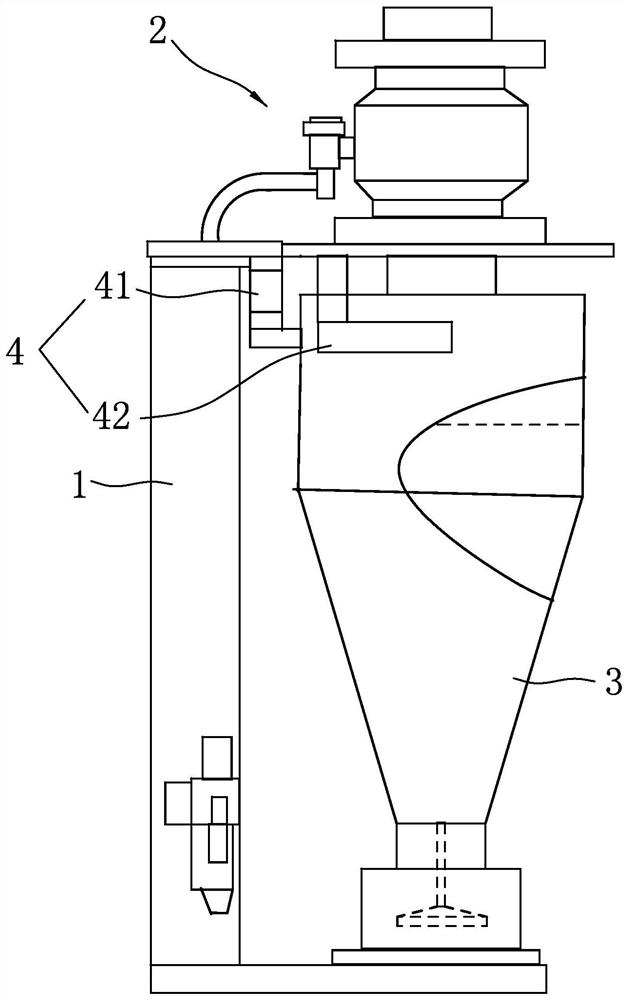

[0044] refer to figure 2 , is the water-absorbent resin adding device used in this embodiment, including a frame and a water-absorbent resin hopper arranged on the frame from top to bottom, a discharge controller, a metering hopper and a feeding device, and the frame is also provided with a control device and metering device, the output end of the metering device, the input end of the discharging controller, and the input end of the feeding device are respectively connected to the controller by communication, and the discharging controller is set under the water-absorbent resin hopper for controlling water absorption Resin feeding, the metering hopper and the water-absorbing resin hopper are arranged vertically separately, the metering hopper is indirectly arranged on the frame through the metering device, the feeding device is separated from the metering hopper and arranged below the metering hopper, and the controller is simultaneously connected with the absorber The host c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com