Biomass charcoal digestion method

A biochar and digestion instrument technology, applied in the preparation of test samples, etc., can solve the problem of low accuracy of test results, achieve complete destruction, low blank value, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

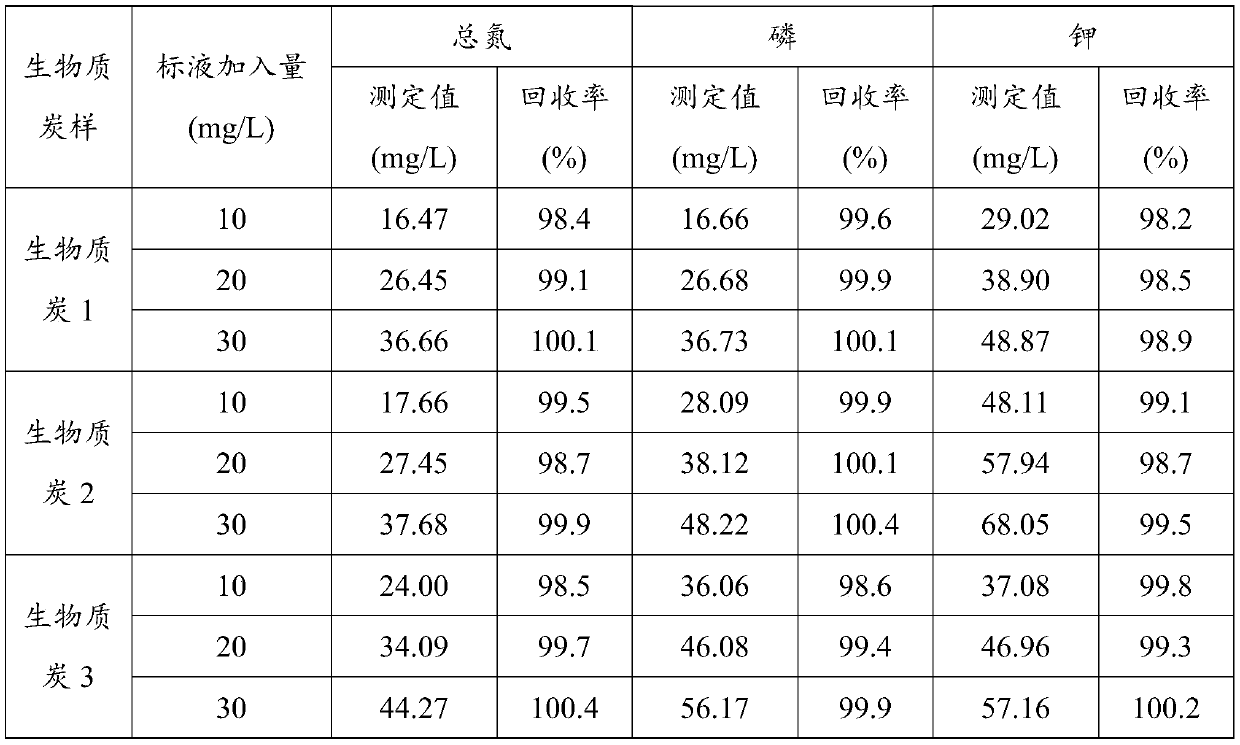

[0028] The present embodiment provides a kind of digestion method of biochar, comprises the steps:

[0029] (1) Weigh 0.05 g of air-dried crop straw charcoal with a particle size of 1 mm, place it at the bottom of the digestion tube, add 5 mL of concentrated sulfuric acid, shake well, and place it overnight;

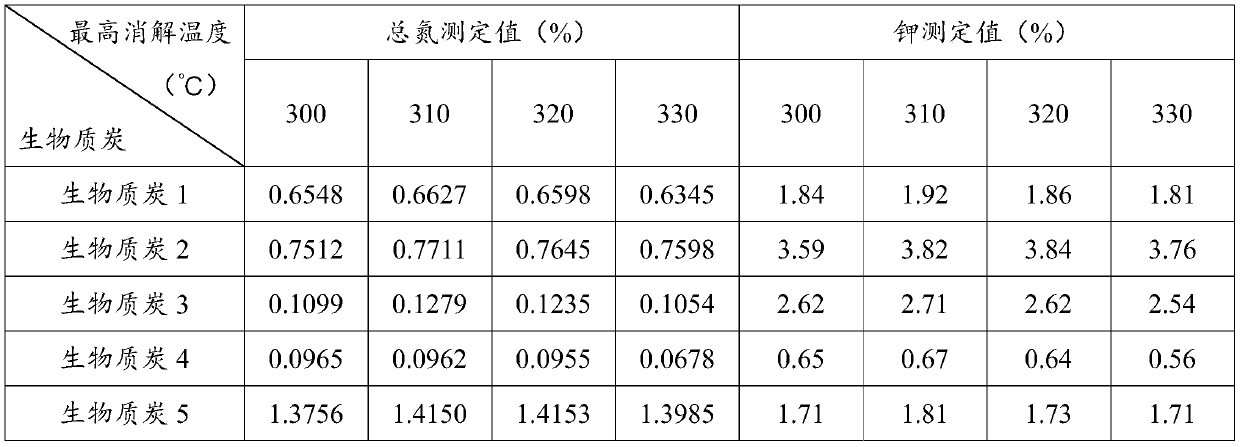

[0030] (2) Place the above-mentioned digestion tube in a temperature-controlled digestion apparatus, raise the temperature to 180°C at a uniform speed, and keep it warm for 30 minutes; continue to raise the temperature at a uniform speed to 250°C, and keep it warm for 20 minutes; continue to raise the temperature at a uniform speed to 310°C, and keep it warm for 40 minutes;

[0031] Wherein, when the temperature rises to 250°C and a large amount of white smoke is no longer produced in the digestion tube, take out the digestion tube, add 30wt% hydrogen peroxide solution in 3 times, mix well, put it back into the temperature-controlled digestion apparatus, and continue dige...

Embodiment 2

[0034] The present embodiment provides a kind of digestion method of biochar, comprises the steps:

[0035] (1) Weigh 0.05 g of air-dried crop straw charcoal with a particle size of 1 mm, place it at the bottom of the digestion tube, add 4 mL of concentrated sulfuric acid, shake well, and place it overnight;

[0036] (2) Place the above-mentioned digestion tube in a temperature-controlled digestion apparatus, raise the temperature to 180°C at a uniform speed, and keep it warm for 30 minutes; continue to raise the temperature at a uniform speed to 250°C, and keep it warm for 20 minutes; continue to raise the temperature at a uniform speed to 300°C, and keep it warm for 40 minutes;

[0037] Wherein, when the temperature rises to 250°C and a large amount of white smoke is no longer produced in the digestion tube, take out the digestion tube, add 30wt% hydrogen peroxide solution in 5 times, mix well, put it back into the temperature-controlled digestion apparatus, and continue dige...

Embodiment 3

[0040] The present embodiment provides a kind of digestion method of biochar, comprises the steps:

[0041] (1) Weigh 0.05 g of air-dried crop straw charcoal with a particle size of 1 mm, place it at the bottom of the digestion tube, add 6 mL of concentrated sulfuric acid, shake well, and place it overnight;

[0042] (2) Place the above-mentioned digestion tube in a temperature-controlled digestion apparatus, raise the temperature to 180°C at a uniform speed, and keep it warm for 30 minutes; continue to raise the temperature to 250°C at a uniform speed, and keep it warm for 20 minutes; continue to raise the temperature to 360°C at a uniform speed, and keep it warm for 40 minutes;

[0043] Wherein, when the temperature rises to 250°C and a large amount of white smoke is no longer produced in the digestion tube, take out the above digestion tube, add 30wt% hydrogen peroxide solution in 4 times, mix well, put it back into the temperature-controlled digestion apparatus, and continu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com