Direct combustion type efficient and energy-saving humidity control denitration catalyst drying system

A denitration catalyst, high-efficiency and energy-saving technology, applied in drying safety systems, drying solid materials, drying gas layout, etc., can solve the problems of easy safety accidents, easy safety problems, low thermal efficiency, etc., to achieve high heat utilization efficiency, reduce The effect of labor cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

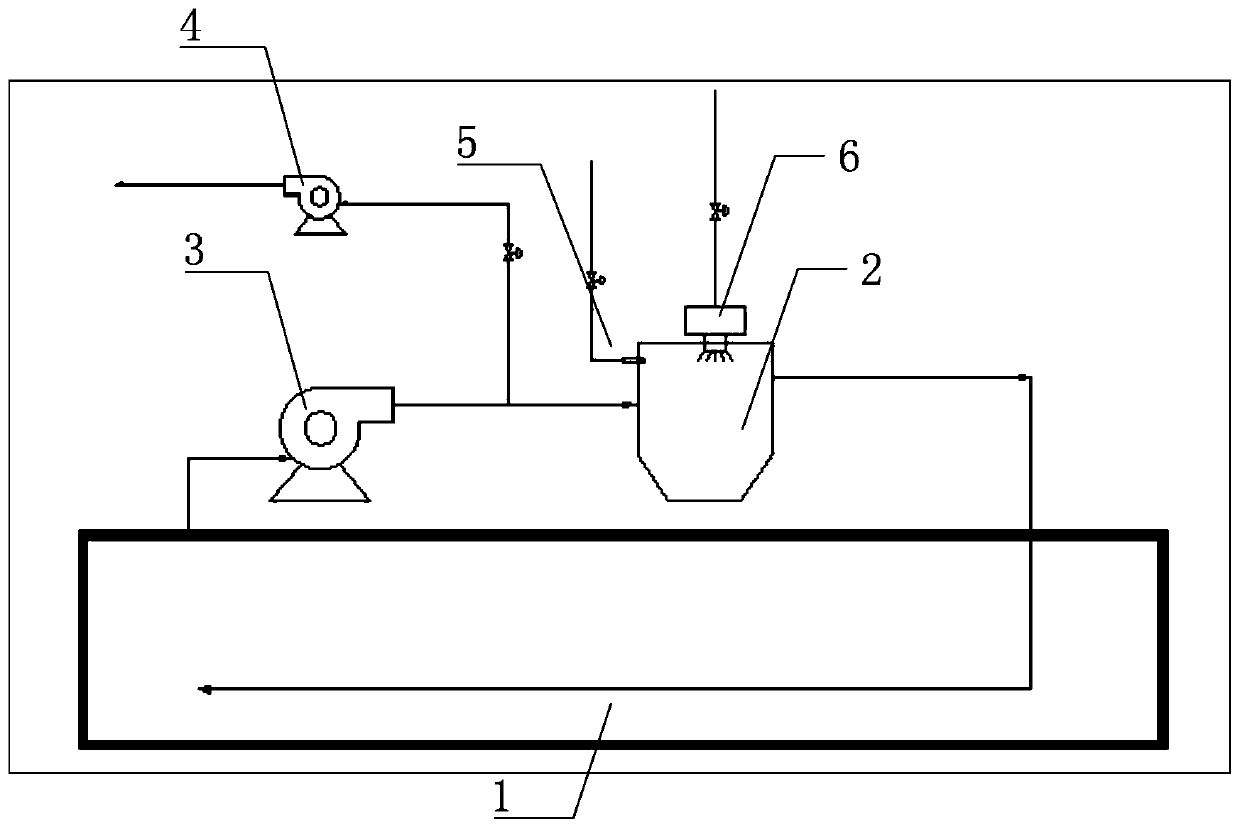

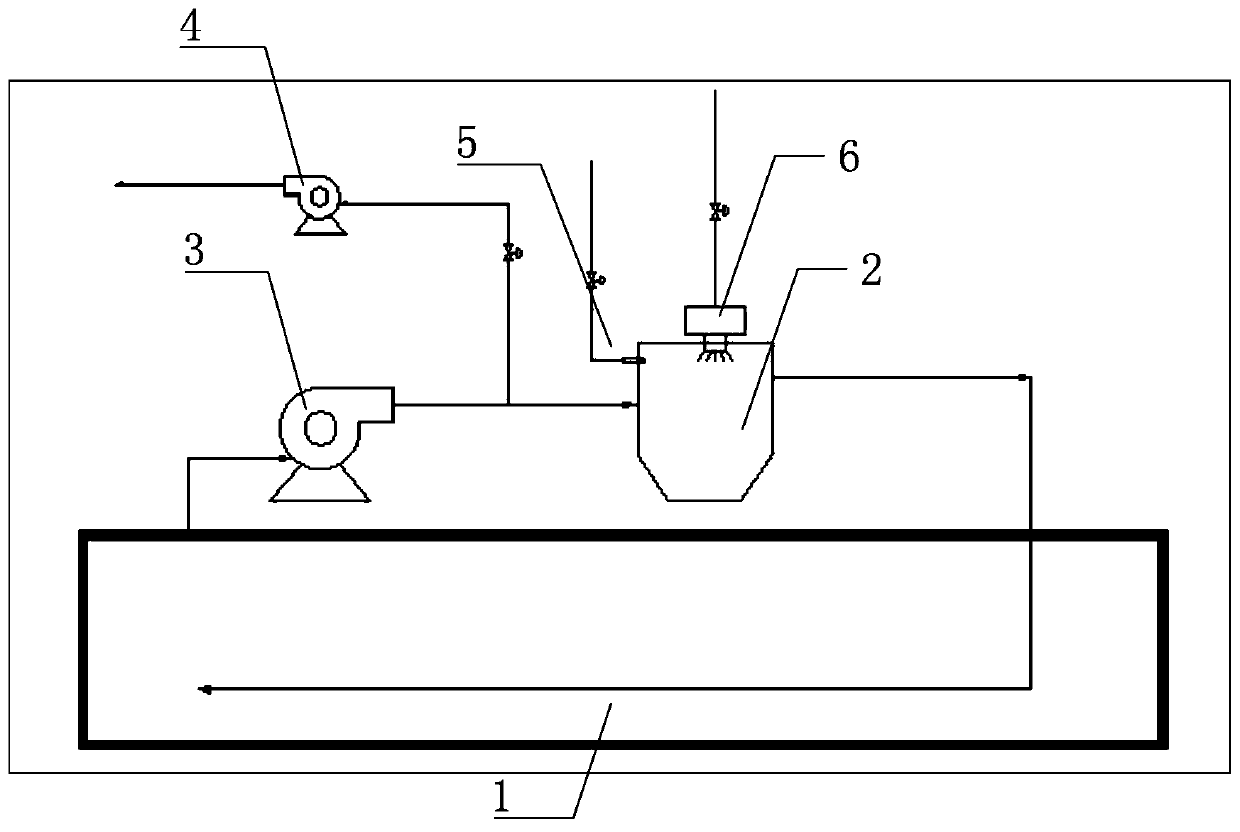

[0020] Such as figure 1 As shown, the present invention provides a direct-fired high-efficiency energy-saving humidity control denitrification catalyst drying system, comprising a primary drying chamber 1, the entrance of the primary drying chamber 1 is connected to a combustion control system and a humidification control system, and the exit of the primary drying chamber 1 is connected to The circulation fan 3 and the humidity exhaust fan 4, the combustion control system includes a burner 6, a combustion chamber 2, a natural gas pipeline and an automatic program control system, the top of the burner 6 is connected to the natural gas pipeline, and the bottom of the burner 6 is connected to the combustion chamber 2; humidification control The system includes a humidification and atomization device 5, a water supply pipe and an automatic control system. The top of the humidification and atomization device 5 is connected to the water supply pipe, and the bottom of the humidificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com