Bidirectional speed regulation hydraulic control system of oil return cavity based on hydraulic cylinder negative load

A technology of hydraulic control system and hydraulic cylinder, which is applied in the directions of fluid pressure actuation system components, fluid pressure actuation devices, servo motors, etc., can solve the problems of hydraulic cylinder climbing, balance valve speed control but not force control, etc., to achieve stable flow , the effect of low failure rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

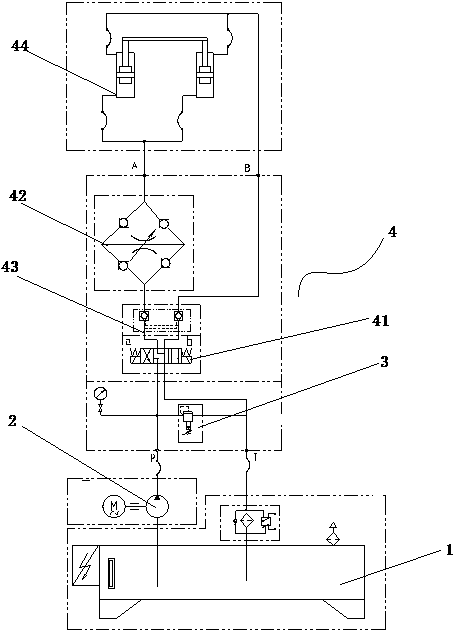

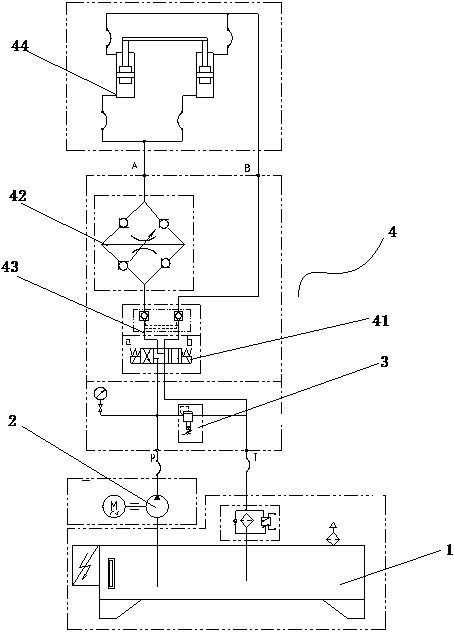

[0019] Such as figure 1 The shown is a two-way speed-regulating hydraulic control system based on the negative load oil return chamber of the hydraulic cylinder, including a fuel tank 1, a power pump 2, an oil source pressure setting valve group 3 and a two-way speed-regulating hydraulic control circuit 4.

[0020] The power pump 2 is driven by a drive motor, and the input end of the power pump 2 extends into the oil tank 1 through a pipeline, and the output end of the power pump 2 is connected to the two-way speed regulating hydraulic control circuit 4 through a pipeline; the oil source pressure The setting valve group 3 is connected in parallel between the output pipeline of the power pump 2 and the oil return port of the fuel tank 1 .

[0021] The two-way speed regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com