Compressed air energy storage type wind driven vertical axis air flotation power generation system

A technology of compressed air energy storage and power generation system, applied in the field of wind power, can solve the problems of increased dead weight of fan blade wind collection system, large suspension power consumption, wind energy capture control lag, etc., to achieve low wind speed start or even breeze start, reduce Suspension power consumption and friction power consumption, improving the effect of wind energy capture power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

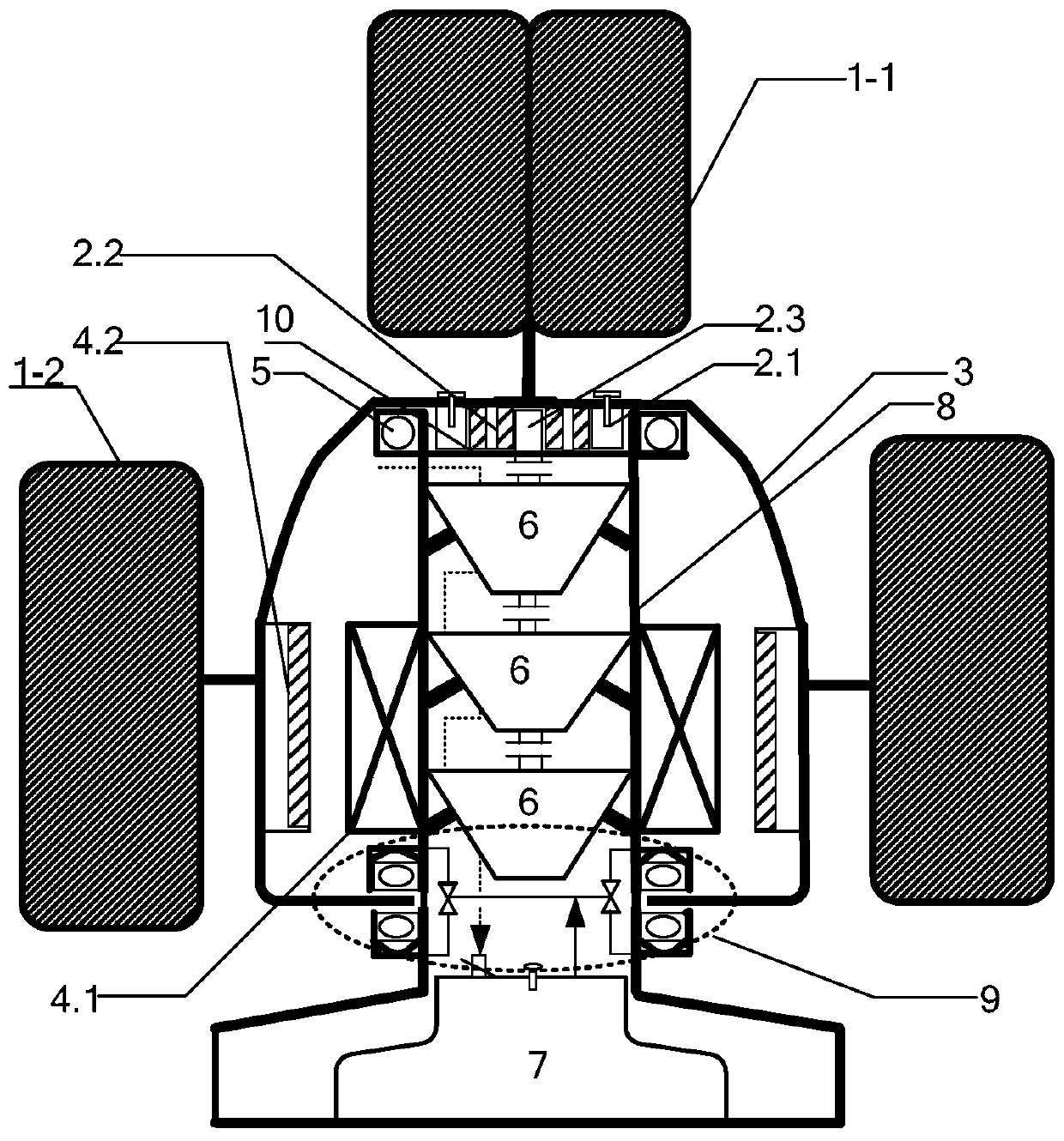

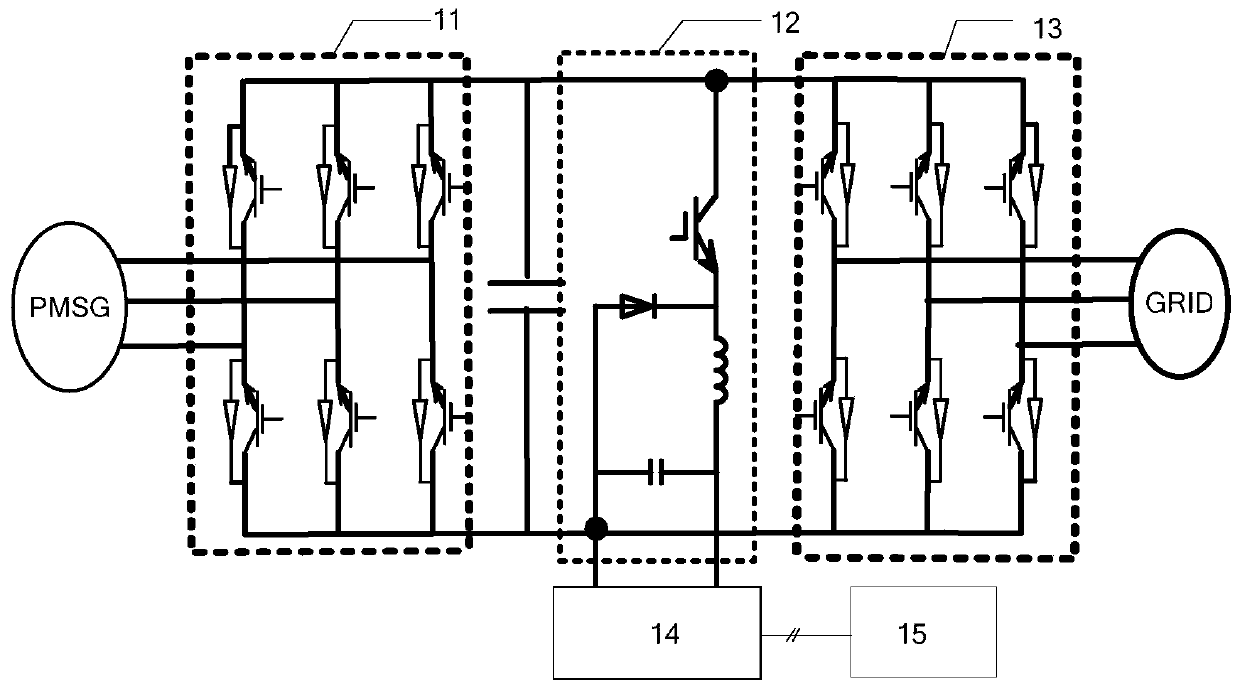

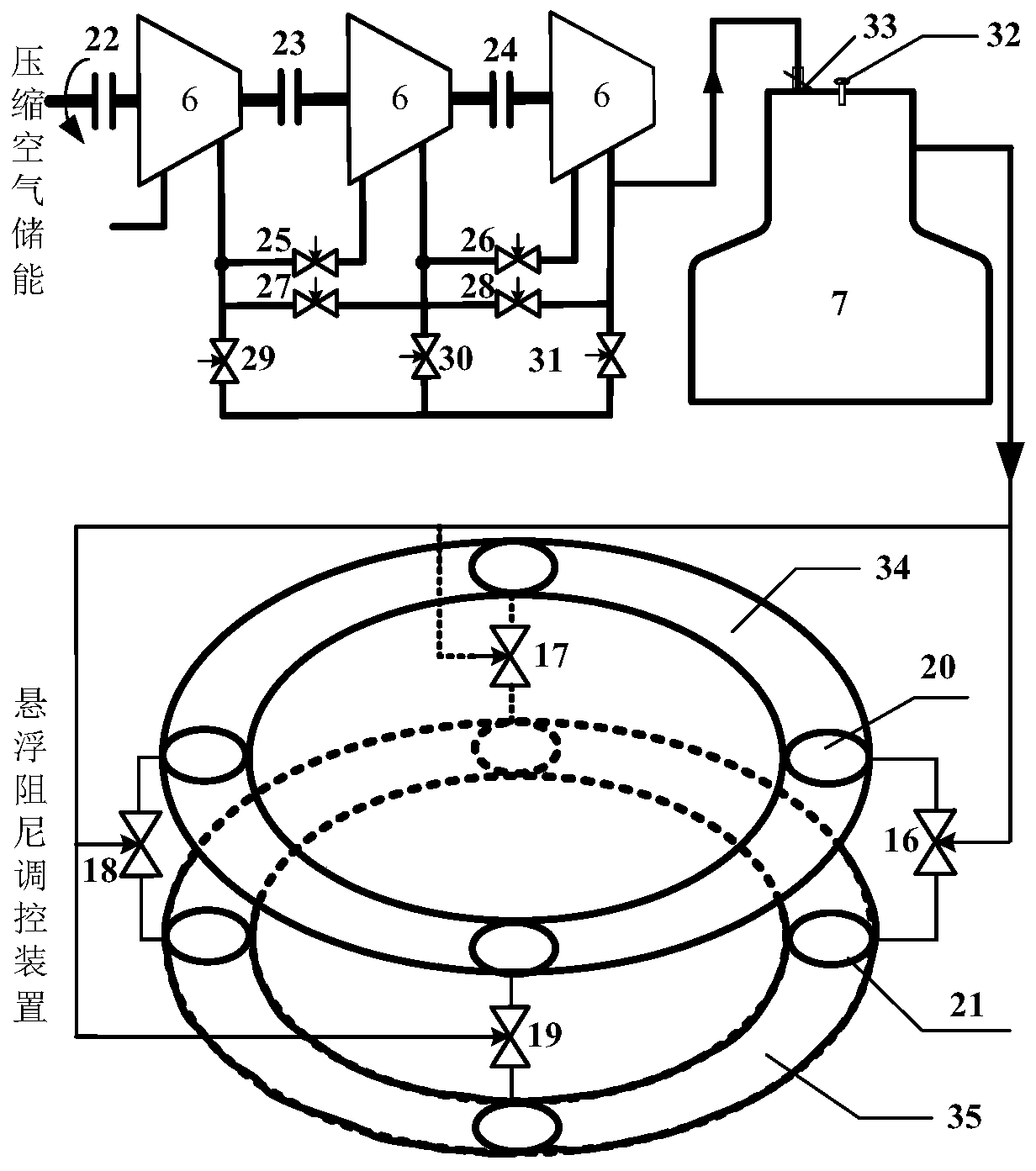

[0018] Such as figure 1 , figure 2 , image 3 As shown, the wind-driven compressed air energy storage type vertical axis air-floating power generation system of the present invention includes: fan blades 1, fan rotating body 3, permanent magnet synchronous generator 4, compressed air energy storage (6,7,22~24,25 ~31), suspension damping control device 9, tower frame 8, mechanical coupling device 2, and converter parts 11~15; fan blades are four sets of two-layer structures, including 1 axial blade 1.1 and 3 diameter Directional blades 1.2, axial blades 1.1 are arranged on the top of the fan rotating body 3, and radial blades 1.2 are distributed on the outside of the fan rotating body according to the principle of equal division; the fan rotating body 3 has a streamlined casing structure, and the top is supported by a tower 8 Circular horizontal rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com