High-speed railway

A high-speed railway and elevated channel technology, applied in the field of transportation, can solve problems such as intolerable vibration and noise, and achieve the effects of noise and pollution reduction, stability improvement, and low energy consumption for suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

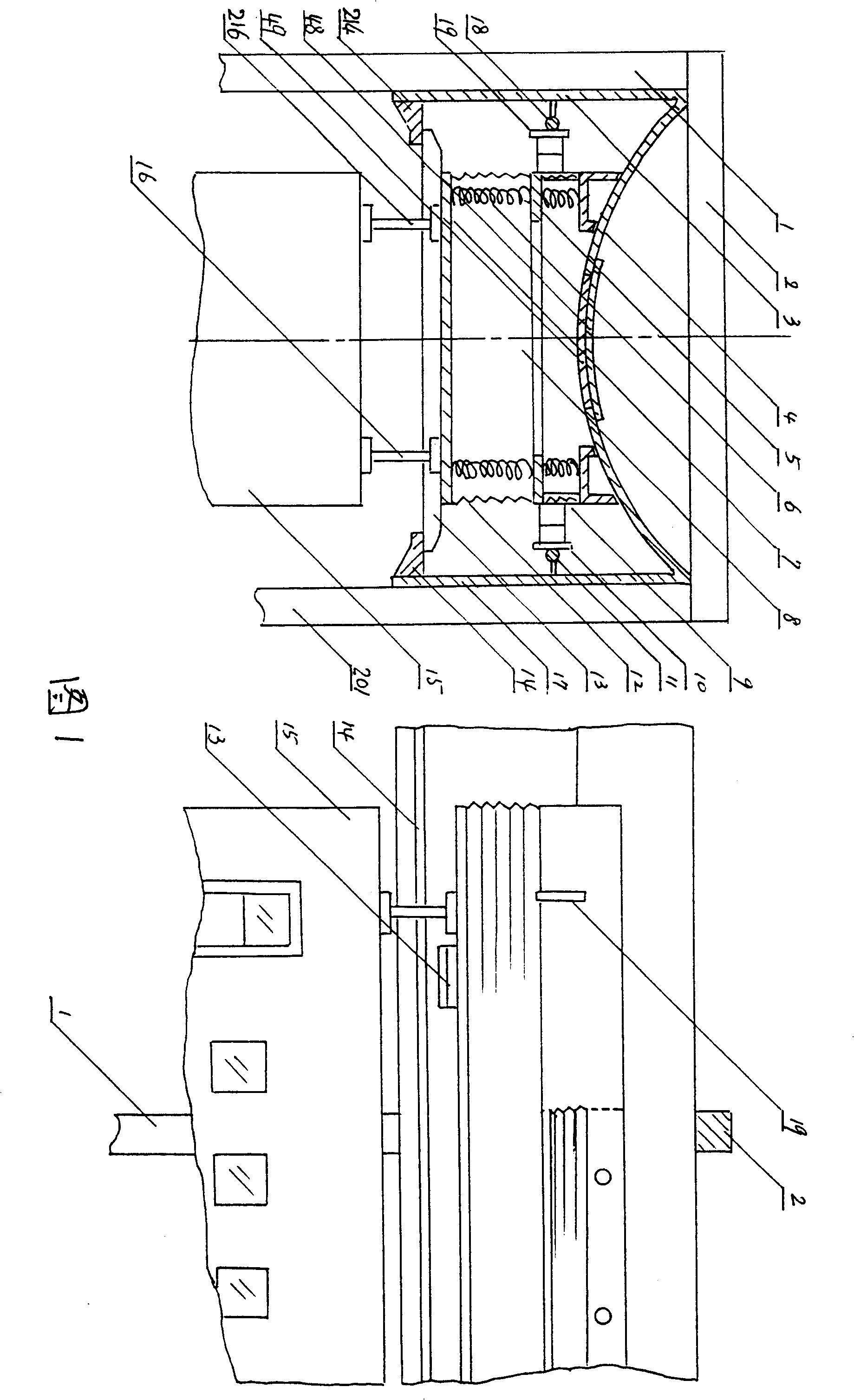

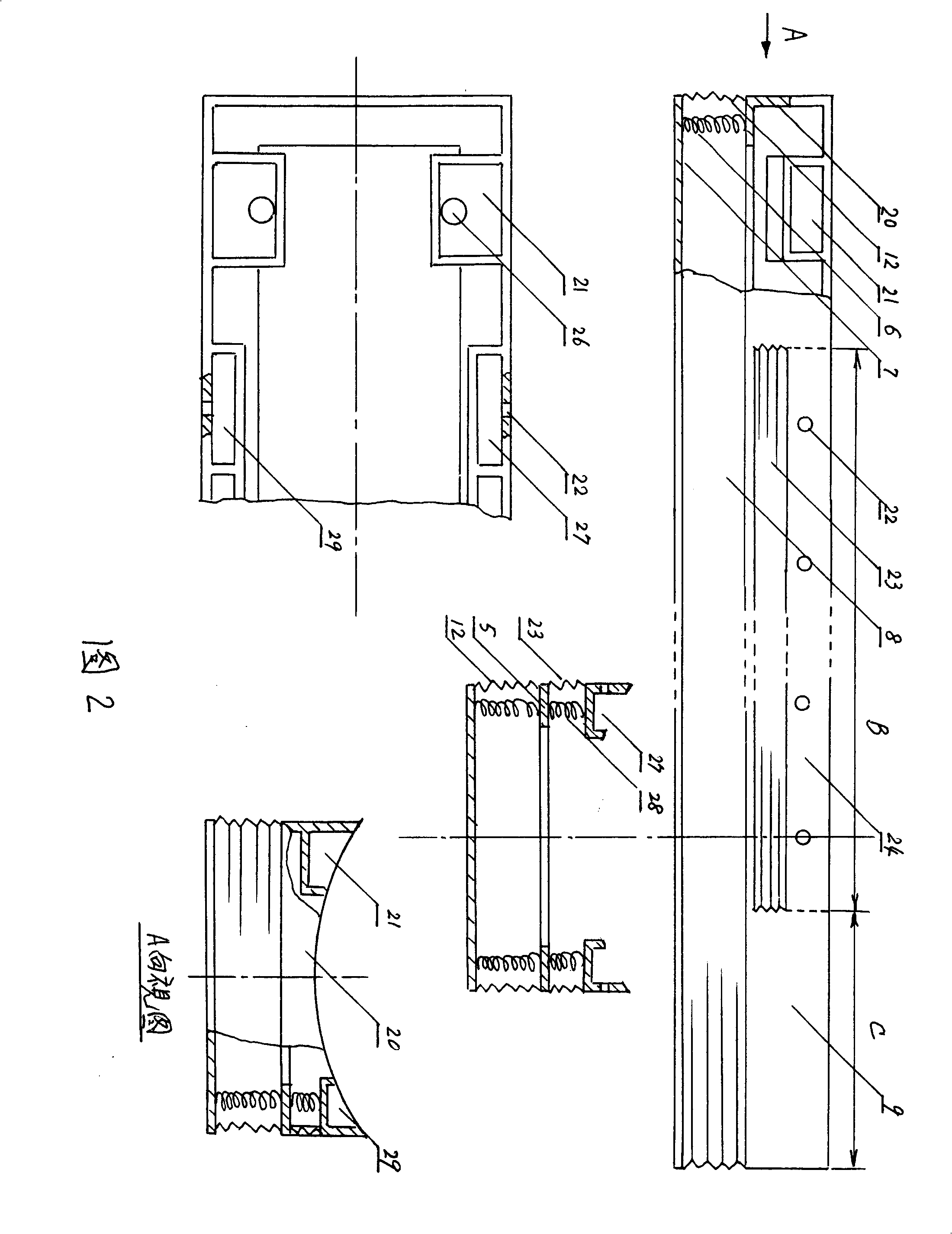

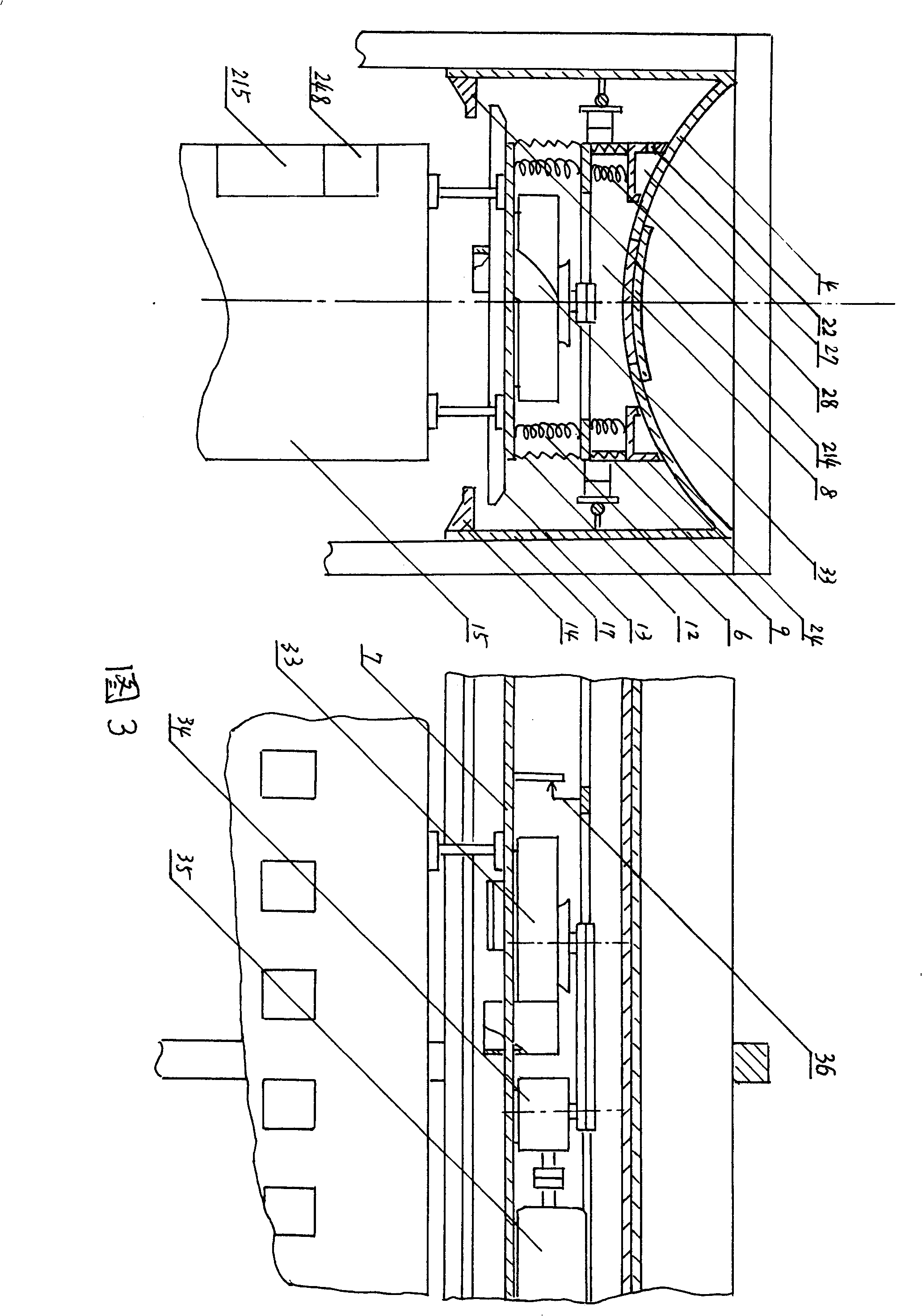

[0046] Fig. 1 has provided the basic structure of the elevated passageway and the suspended carriage of a kind of high-speed railway embodiment (1) of the present invention. On the elevated passage, the left and right ends of the overhead horizontally placed beam 2 are supported by symmetrically standing brackets 1 and 201. The brackets are evenly arranged on both sides along the railway line at a certain interval, and the roots of the brackets are fixed on the ground. in the concrete foundation. The beam 2 and the support 1, 201 can be made of steel. Be fixed with the top plate 4 of overhead passage below crossbeam 2, the cross-section of top plate 4 is the arc shape of concave, and its center of circle is directly above top plate 4. The secondary composite reaction plates 48 and 49 as the secondary composite reaction plates for driving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com