Polycrystalline silicon ingot preparation technology

A polycrystalline silicon ingot and process technology, applied in the directions of polycrystalline material growth, crystal growth, single crystal growth, etc., can solve the problems of intensified solid-phase diffusion, small thermal shock, poor quality of polycrystalline silicon ingots, etc., to reduce the level of dislocation defects, The effect of reducing dislocation slip proliferation and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

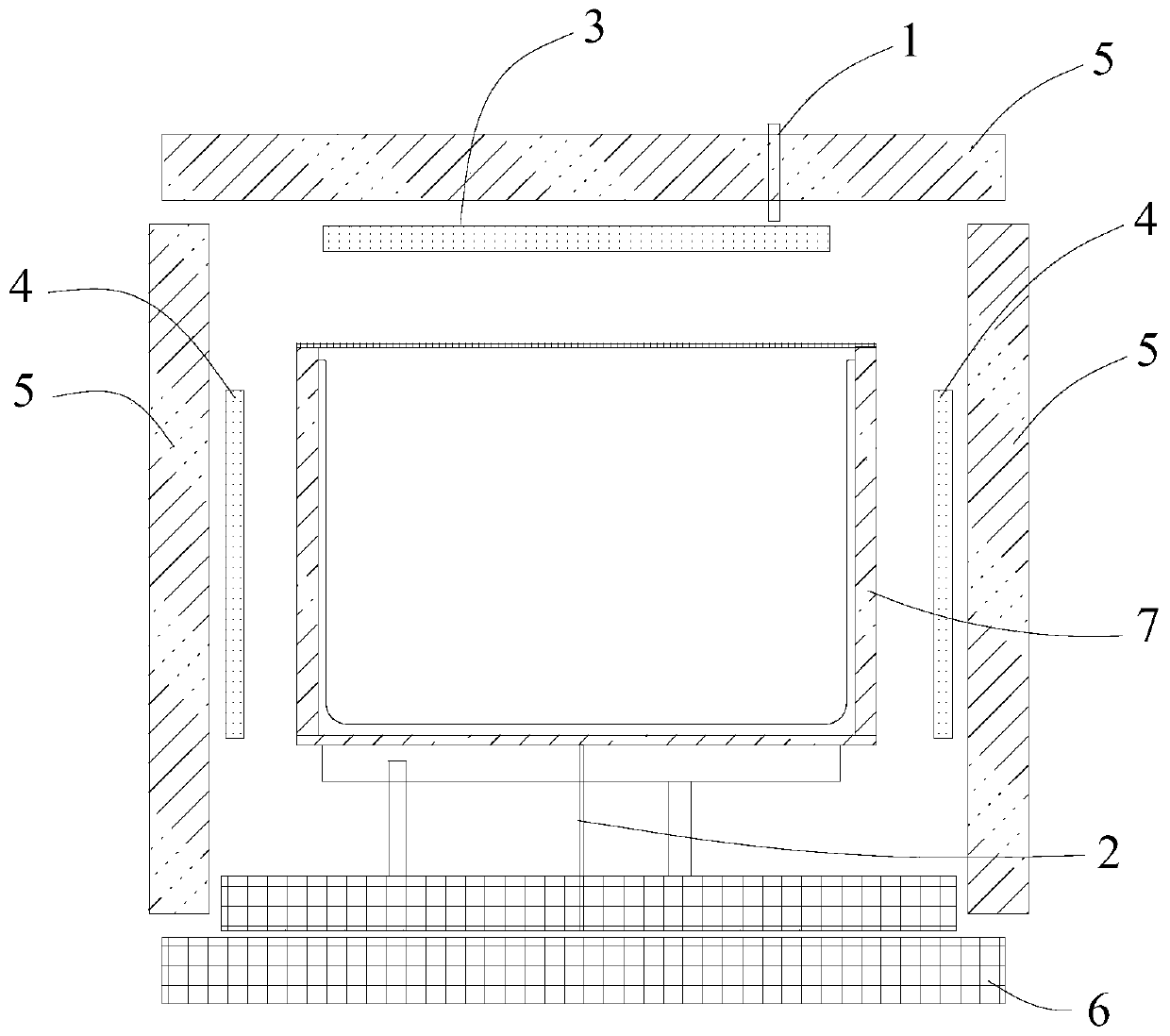

[0040] This embodiment provides a process for casting polycrystalline silicon ingots. In this process, figure 1 The polysilicon ingot casting device shown. The technique of the present embodiment comprises the following steps:

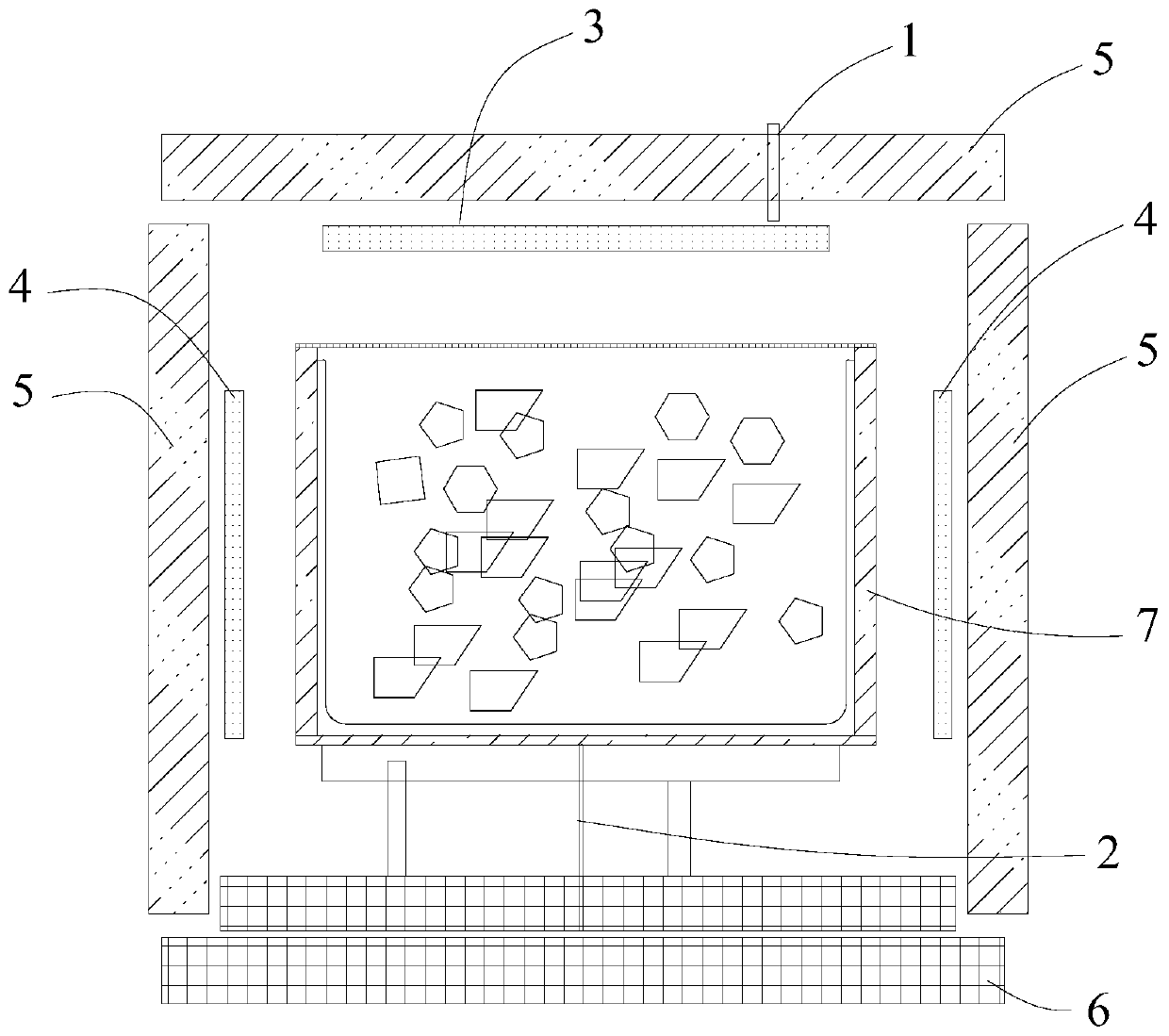

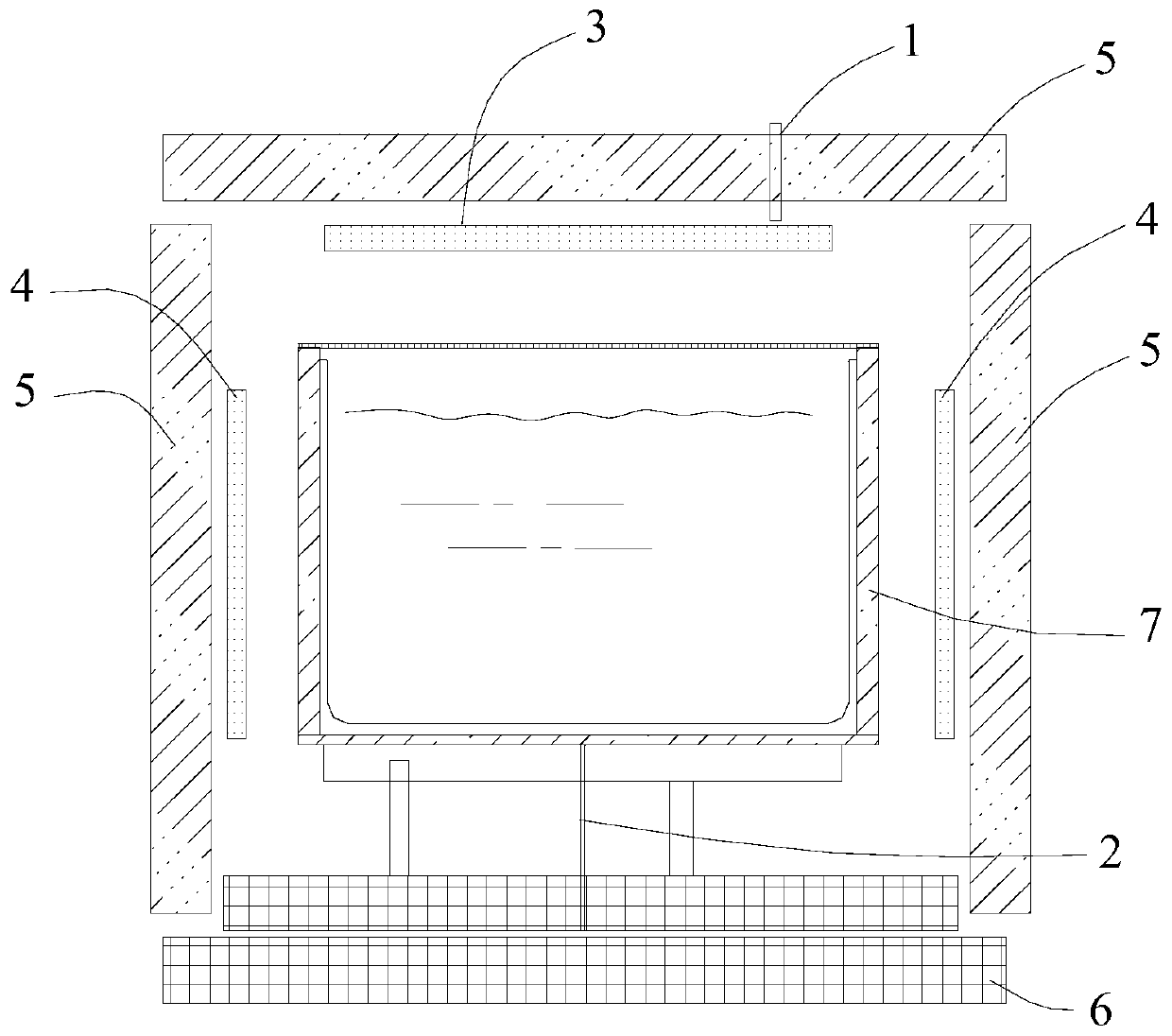

[0041] Step 1. In the heat insulation cage 5 with the bottom plate 6, use the top heater 3 and the side heater 4 to heat the crucible 7 containing the silicon material to above 1540 ° C, so that the silicon in the crucible 7 The material is melted to form a silicon melt; such as figure 2 with image 3 as shown, figure 2 It is a schematic diagram of the state of the polysilicon ingot casting device before heating, image 3 It is a schematic diagram of the state of the polysilicon ingot casting device after heating, from figure 2 with image 3 It can be seen from the comparison that the state of polysilicon in the crucible 7 changes from solid silicon material to liquid silicon melt;

[0042] Step 2, open the bottom plate 6 of the heat insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com